02.08.18

The year 2018 will be a milestone for Novaled in the company’s history, because the move to the new premises in Dresden will be kicked off in the second half of the year.’

On the 10,200 square meter plot, the interior construction of the buildings is currently in full swing. The monument protected historic mill with office space and the R&D plant with research areas, clean rooms of classes ISO5 and ISO7 as well as laboratories have a combined floor area of 6,160 square meters.

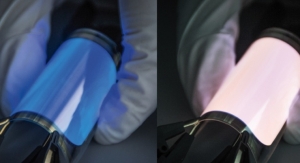

In addition to investments in property and buildings, Novaled invests also in increased capacities for the development and production of organic materials at the new headquarters. Laboratories and cleanrooms will be fully equipped with state-of-the-art tools. This also includes investments in high-precision, high-performance OLED deposition systems for the production of organic light-emitting diodes to qualify new materials.

Accordingly, Novaled recently entered into a purchase and delivery agreement for OLED deposition systems from Sunic System for $3 million. This increases the capacity for OLED production by 40% and at the same time enables an even more precise repeatability in processing. The new equipment will significantly accelerate the development, testing and qualification of novel organic materials for high-efficiency, long-life OLEDs.

Novaled is currently the only supplier of organic dopants for OLED display mass production globally, with its materials found in most smartphones, tablets and other devices with OLED displays.

Source: Novaled

On the 10,200 square meter plot, the interior construction of the buildings is currently in full swing. The monument protected historic mill with office space and the R&D plant with research areas, clean rooms of classes ISO5 and ISO7 as well as laboratories have a combined floor area of 6,160 square meters.

In addition to investments in property and buildings, Novaled invests also in increased capacities for the development and production of organic materials at the new headquarters. Laboratories and cleanrooms will be fully equipped with state-of-the-art tools. This also includes investments in high-precision, high-performance OLED deposition systems for the production of organic light-emitting diodes to qualify new materials.

Accordingly, Novaled recently entered into a purchase and delivery agreement for OLED deposition systems from Sunic System for $3 million. This increases the capacity for OLED production by 40% and at the same time enables an even more precise repeatability in processing. The new equipment will significantly accelerate the development, testing and qualification of novel organic materials for high-efficiency, long-life OLEDs.

Novaled is currently the only supplier of organic dopants for OLED display mass production globally, with its materials found in most smartphones, tablets and other devices with OLED displays.

Source: Novaled