06.07.18

The business unit Precision Coatings at Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP has special expertise in developing deposition processes for high-precision coating systems on optical components. Now, a coating technology for deposition of laterally graded optical layers on 2D and in the future also on 3D substrates has been developed. The results will be presented at the 2nd OptecNet Annual Conference in Berlin, June 20-21, 2018.

Light plays an important role in more and more economic sectors and markets – including in data transmission, communication, energy generation, laser processing, and classical optics. Accordingly, the demands placed on high-performance optical products and systems are increasing rapidly. Components and integrated optical systems are becoming increasingly complex.

Recently, a team of researchers from science and industry was awarded the “Forschung im Verbund” joint industry and science prize for the latest developments in free-form optical systems. Use of increasingly complex surfaces in optics means the complexity of the coatings also increases.

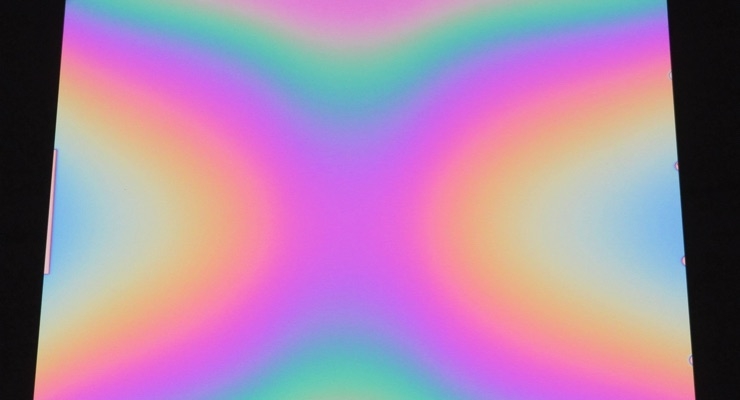

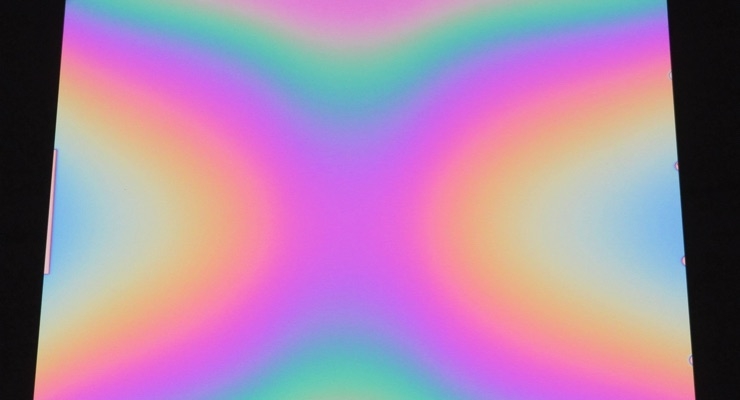

The scientists at Fraunhofer FEP have now succeeded in developing new processes and coating technologies that can be used for complex surfaces of large optical components. Specifically, this involves fabrication of lateral gradient layer systems. The objective of this research is to manufacture optical layer systems adapted to applications characterized by variable angles of incidence, such as waveguides in holography, head-up displays, laser illumination, and laser processing systems. One focus has also been adapting the coating technology to larger surfaces, as a trend towards larger substrates with curved surfaces has become apparent.

The results make it feasible to better adapt to specific customer requirements by locally adjusting the optical function of optical multilayer systems. This applies in particular to coatings on large substrates or 3D substrates, where the incident angle of the light locally varies in the application. The optical function now can be adapted to the given incident angle of light.

“The requirements for process control are very high,” Dr. Daniel Glöß, head of department Dynamic Coating, said. “We basically have to adjust the coating thickness locally, which can be done either by accelerating the substrate movement during deposition or by varying the coating rate as a function of the substrate location. In both cases, we need very precise substrate movement. With the PreSensLine, we have a coating system with the means for precision movement. The system control has now been adapted so that we can manufacture such coatings and offer them on a customer-specific basis.”

Through the joint research project “TopBePro” together with with AIS Automation Dresden GmbH, LSA GmbH and dresden elektronik ingenieurtechnik GmbH, Fraunhofer FEP scientists are now able to exert very precise temporal control over the different components (precision drive, coating sources, and power supply).

Source: Fraunhofer FEP.

Light plays an important role in more and more economic sectors and markets – including in data transmission, communication, energy generation, laser processing, and classical optics. Accordingly, the demands placed on high-performance optical products and systems are increasing rapidly. Components and integrated optical systems are becoming increasingly complex.

Recently, a team of researchers from science and industry was awarded the “Forschung im Verbund” joint industry and science prize for the latest developments in free-form optical systems. Use of increasingly complex surfaces in optics means the complexity of the coatings also increases.

The scientists at Fraunhofer FEP have now succeeded in developing new processes and coating technologies that can be used for complex surfaces of large optical components. Specifically, this involves fabrication of lateral gradient layer systems. The objective of this research is to manufacture optical layer systems adapted to applications characterized by variable angles of incidence, such as waveguides in holography, head-up displays, laser illumination, and laser processing systems. One focus has also been adapting the coating technology to larger surfaces, as a trend towards larger substrates with curved surfaces has become apparent.

The results make it feasible to better adapt to specific customer requirements by locally adjusting the optical function of optical multilayer systems. This applies in particular to coatings on large substrates or 3D substrates, where the incident angle of the light locally varies in the application. The optical function now can be adapted to the given incident angle of light.

“The requirements for process control are very high,” Dr. Daniel Glöß, head of department Dynamic Coating, said. “We basically have to adjust the coating thickness locally, which can be done either by accelerating the substrate movement during deposition or by varying the coating rate as a function of the substrate location. In both cases, we need very precise substrate movement. With the PreSensLine, we have a coating system with the means for precision movement. The system control has now been adapted so that we can manufacture such coatings and offer them on a customer-specific basis.”

Through the joint research project “TopBePro” together with with AIS Automation Dresden GmbH, LSA GmbH and dresden elektronik ingenieurtechnik GmbH, Fraunhofer FEP scientists are now able to exert very precise temporal control over the different components (precision drive, coating sources, and power supply).

Source: Fraunhofer FEP.