11.13.18

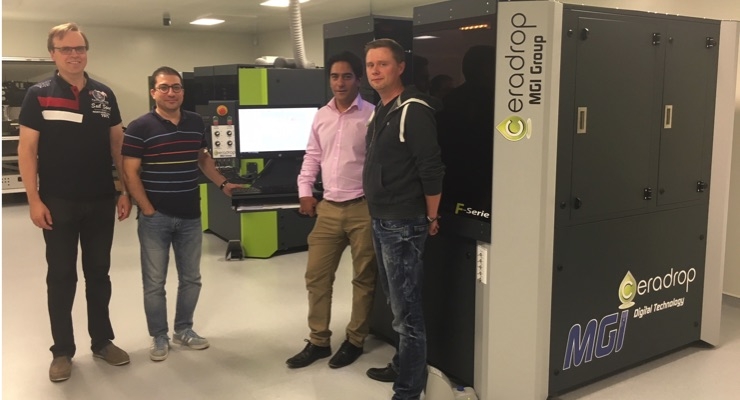

CERADROP, an MGI Group company, expanded its horizon and welcomed a new customer and partner – The Tampere University of Technology.

TUT is located in Tampere, the Nordic countries’ largest inland city, and conducts research in the fields of technology and architecture.

“The CeraPrinter F-Serie enables complex functional multi-material components design, printing and characterization and represents a breakthrough for emerging applications in organic and printed electronics,” said Nicolas Bernardin, sales and business development director, CERADROP. “Providing our customers with such an all-in-one tool for complex systems is in the core of our company’s mission.”

The CERADROP F-Serie is operating in the Laboratory for Future Electronics of Tampere University of Technology, Finland, for the additive manufacturing of high-resolution thin-film electronics, energy-autonomous sensors, conformable wearable electronics (soft/stretchable, on-skin, textile), and hybrid systems.

According to TUT Professor Matti Mäntysalo, the main advantages of the technology:

TUT is located in Tampere, the Nordic countries’ largest inland city, and conducts research in the fields of technology and architecture.

“The CeraPrinter F-Serie enables complex functional multi-material components design, printing and characterization and represents a breakthrough for emerging applications in organic and printed electronics,” said Nicolas Bernardin, sales and business development director, CERADROP. “Providing our customers with such an all-in-one tool for complex systems is in the core of our company’s mission.”

The CERADROP F-Serie is operating in the Laboratory for Future Electronics of Tampere University of Technology, Finland, for the additive manufacturing of high-resolution thin-film electronics, energy-autonomous sensors, conformable wearable electronics (soft/stretchable, on-skin, textile), and hybrid systems.

According to TUT Professor Matti Mäntysalo, the main advantages of the technology:

- High-accuracy printing with excellent layer-to-layer registration;

- Support of various inkjet heads from disposable cartridges to high-quality industrial heads;

- Integrated drop watcher with software for automated drop analysis;

- Integration of online annealing units i.e. UV LED and near infrared;

- Integrated 4-point resistance measurement system;

- Fully integrated software, with a single interface, for print file/program design, printing, post-printing processes, and post-printing characterization