06.13.19

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory.

A scientific sandbox and technology accelerator, the MDF is easily accessible by industrial and academic partners wanting to team up with national lab experts on big challenges manufacturers face. MDF researchers at the forefront of materials and deposition science have worked with more than 180 companies to create metal and polymer feedstocks and processing systems to 3D print complex objects from human prosthetics to tools for making building facades.

“We’re looking at understanding how we control various additive processes to create structural and functional materials that were never before possible,” said ORNL’s Ryan Dehoff, who works on robotic, aeronautic and automotive projects at the MDF. “Extremely demanding applications are a whole area of additive manufacturing that the national labs are exploring.”

MDF researchers concurrently develop 3D-printing systems, the materials used in the printers, and the diverse applications the printers and materials enable.

“Many institutions are experts in one of these areas,” said ORNL composites engineer Vlastimil Kunc. “But if you are developing materials and have limited access to modifying your equipment, very quickly you will run into limitations that stifle your innovation.”

Compared to conventional manufacturing, additive manufacturing methods employed at the MDF use less material and energy and add new capabilities. MDF researchers are exploring ways to make polyesters 3D-printable with Polynt, a supplier of polymers for a variety of products. They are 3D printing rare-earth-containing magnets for energy-generation and high-tech applications. And while working to identify bioderived feedstocks, they 3D printed pavilions for the 2016 Design Miami expo using bamboo fiber in a matrix polymer. The pavilions survived Hurricane Irma the following year.

Synergistic partnerships

“Industry is amazing and does incredible things, but at the end of the day, industry has to make a profit and therefore has to be a bit more cautious with R&D,” said Dehoff. “We can help them push the bounds and mitigate risk associated with implementing advanced manufacturing.”

The MDF model requires a one-to-one cost match and allows companies to access ORNL’s capabilities and expertise while protecting their intellectual property through business agreements. Among the participants are Dixie Chemical Company, which seeks ways to 3D print with epoxies, and TCPoly, which works with ORNL through the Innovation Crossroads program to 3D print plastics that are highly thermally conductive.

MDF’s research expertise and equipment are so valuable that partners beyond industry have allied themselves with the facility to accelerate their progress. Other DOE labs have collaborated, such as Lawrence Livermore National Laboratory, which connects via a program that uses high-performance computing to advance manufacturing. So too have military organizations, such as Wright-Patterson Air Force Base, which teams up on data frameworks for simulations. Especially active are university partnerships, such as with the University of California at Santa Barbara to characterize metal materials and Penn State to model fluid flow in additive manufacturing. Many students of Suresh Babu, Governor’s Chair in Additive Manufacturing at the University of Tennessee, participate in MDF research as well.

ORNL has decades of experience collaborating with partners on materials characterization, development, processing, and modeling and simulation. The lab can offer best practices as well as tools for design, fabrication, costing, qualification and certification to reduce risks to commercialization. MDF partners have access to renowned experts and instruments that have provided unparalleled insight into the materials under development for 3D printing at ORNL’s Spallation Neutron Source, High Flux Isotope Reactor, National Transportation Research Center, Oak Ridge Leadership Facility and Center for Nanophase Materials Sciences.

Approximately 80 ORNL researchers focus primarily on additive manufacturing. About 100 more share their expertise in advanced materials, supercomputing, neutron science, national security and clean energy.

“The strength of ORNL is being able to draw on experts with diverse backgrounds that are all world-renowned in their fields,” Dehoff said.

Advancing materials

Pioneering research and development are critical to certifying robust materials, resilient components and reliable processes for next-generation vehicles, buildings and power plants. With a long history of materials science excellence stretching back to its founding in 1943, ORNL advances metal and polymer feedstocks for additive manufacturing.

“Only a handful of materials are used in additive manufacturing today,” said Dehoff, who leads R&D of metals. “Oak Ridge has a lot of expertise in designing new materials that take advantage of the rapid solidification conditions that you typically see in the melting process.”

To predict stress responses, experimentalists measure materials of various shapes under different conditions, and theoreticians develop numerical methods for modeling and simulation.

Recent metals research includes processing of powdered alloy feedstocks that can be melted with an electron beam or laser in a guided way to control defects that can shorten an object’s lifespan. If a manufacturer is fabricating a part with this technique and something goes wrong, that fine control opens the door to the ability to fix a defect before moving on.

“Real-time repairs are becoming possible,” Dehoff said. “Our core R&D program pushes the boundaries of additive manufacturing related to controlling the microstructure and mechanical response of materials. This is groundbreaking in the additive manufacturing world. It’s really hard to do – but that’s why a national lab should be doing it.”

National labs can also help industry use less material. For every 10 pounds of titanium purchased to manufacture an airplane, only 1 pound goes on the plane, Dehoff approximated. Titanium material goes to scrap for pennies on the dollar. Topology optimization – designing parts to decrease weight while preserving function – can cut half the weight. “You get a lot of energy efficiency from not having to fly around all that additional weight,” he said.

In polymers research, top advances include characterizing microstructure to create a better understanding of material properties, stabilizing chemistry to improve printability and customizing equipment to optimize processes to deposit thermoplastics and liquid polymers.

This new knowledge can help innovators deal with competing demands during materials processing. “To print a polymer as fast as possible, the material should have low viscosity and flow like water,” Kunc said. “But as soon as the material is out of the nozzle, it needs to maintain its shape and support subsequent layers. For that, the polymer must have high viscosity.”

At the MDF, companies can examine small-scale research batches (say, 100 grams) before committing money and materials to produce large-scale batches (say, 1 ton) at industrial plants. Multi-materials such as syntactic foams filled with lightweight particles or fiber-reinforced composites, present special challenges at interfaces between materials.

“Problems at the interface drive the science,” said Kunc, pointing to a small batch of highly filled polymer that had separated into layers like loosely stacked potato chips. “If you don’t know the underlying science and process, this is what you would end up with.”

Equipment that excels

Companies make major investments in additive manufacturing at their own facilities. The fact that they also do so at the MDF emphasizes the shared role in helping manufacturers with problems too great to solve alone. Engineering solutions require shared resources and increased capacity.

“Companies frequently place a high-value printer on our floor and supply a lot of developmental material to us at no cost,” Kunc said. “That ensures that we increase the competitiveness of our U.S. industry partners because when they make these commitments to our joint development, they have expectations of us and skin in the game.”

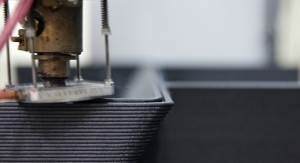

With Cincinnati Incorporated, ORNL co-developed the Big Area Additive Manufacturing (BAAM) system, renowned for 3D printing a prototype car, house and submarine. The BAAM system at the MDF was also used to produce a trim tool that holds the Guinness world record for the largest 3D-printed object; Boeing used it to make components for its 777X aircraft.

ORNL co-developed the world’s first large-scale thermoset printer with Magnum Venus Products. Chemical reactions between layers enable better mechanical properties, and controllable chemistry allows for high-resolution solid features.

What’s more, MDF houses the world’s first printer of multi-materials from thermoplastics, including bioderived materials, to thermosets. Large-scale feedstocks were once available only as filaments, and additive manufacturers paid a premium for that form. Now, pelletized feedstock can be 100 times cheaper.

Because MDF researchers don’t want a high-value advanced 3D printer to idle, they designed removable printer beds that can be swapped out quickly. They also developed an algorithm that gets around a constraint that forces other printers to lay down material with starts and stops. Theirs is the only additive manufacturing done via continuous printing. A patent is pending for these developments.

Tooling is an area where 3D printers shine. To 3D print an airplane winglet, for example, a sheet of composite material is placed on a shaping tool, and the whole assembly goes into an autoclave where heat, pressure and vacuum adhere the composite firmly to the tool and remove gases that create porosity. In conventional manufacturing, such tooling is expensive to make. Now the shaping tools themselves can be made of 3D-printed composites.

Yet, those 3D-printed composites, like many other 3D-printed objects, need functional surfaces that are smoother than 3D printing can currently deliver. “That is where machining (or subtractive manufacturing) comes in,” said Scott Smith, who leads machining and machine tool research at ORNL. “At the MDF, we are working on the best ways to combine additive and subtractive manufacturing technologies to reduce costs, improve quality, reduce energy consumption and produce parts with new functionality. These ideas were unthinkable just a few short years ago, but they are becoming reality today.”

In six weeks, the MDF team 3D printed a composite mold for manufacturing wind turbine blades that typically takes six months. Such agility is good news for the U.S. manufacturing sector, bent on speeding innovative products from laboratory to marketplace.

When industry asked for the capability to 3D print Inconel 718, a nickel-based superalloy for aerospace and energy applications that remains strong at high temperatures, MDF researchers developed the technology and have since printed with Inconel 738 and Mar M 247 – even more advanced superalloys. Credit: Oak Ridge National Laboratory, U.S. Dept. of Energy; photographer Jason Richards

When industry asked for the capability to 3D print Inconel 718, a nickel-based superalloy for aerospace and energy applications that remains strong at high temperatures, MDF researchers developed the technology and have since printed with Inconel 738 and Mar M 247 – even more advanced superalloys. Credit: Oak Ridge National Laboratory, U.S. Dept. of Energy; photographer Jason Richards