Years of out-of-the-box thinking have yielded a broad range of design concepts for the marine energy industry.

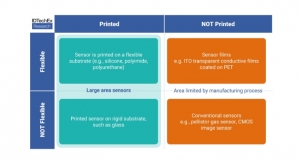

While the three-bladed axial flow turbine has long defined the wind industry, marine energy devices include a wide variety of concepts, including tidal turbines, wave point absorbers, river current turbines, and oscillating water columns, each of which is uniquely suited for certain operating conditions. Without one approach outperforming the others, the nascent water power industry is busy experimenting with various options.

Marine energy devices that can capture energy from water bodies take many shapes, as shown in these reference model illustrations. Image from Sandia National Laboratories

Marine energy system developers, therefore, have a pressing need for more efficient and cost-effective prototyping techniques. To fill this innovation gap, researchers at the National Renewable Energy Laboratory (NREL) and Montana State University set out to explore the potential for rapid prototyping using additively manufactured composite molds.

With $75,000 in funding from the U.S. Department of Energy Water Power Technologies Office's Water Power Laboratory Seedling Program, the researchers began a year-long effort to combine additive and composite manufacturing techniques into a faster, cheaper, and more repeatable process.

NREL's Manufacturing and Characterization research group has previously partnered with Montana State University and Sandia National Laboratories to innovate manufacturing materials and geometries related to wind power.

Using NREL's Composites Manufacturing Education and Technology (CoMET) Facility, the team has demonstrated experience using state-of-the-art manufacturing techniques to simulate and model wind turbine blade designs.

In recent years, the wind industry has explored the benefits of applying large-scale additive manufacturing techniques to create complex blade mold sections that can be bonded.

The process involved in this technique shows promise for overcoming transportation barriers by allowing for on-site manufacturing of large wind turbine blades.

However, the process remains both expensive and time-consuming, and it is thus justifiable only on the massive scales occurring in the wind industry.

"This Seedling project has roots in our previous work with wind and tidal turbine blade manufacturing," said Paul Murdy, a postdoctoral researcher at NREL who acted as the principal investigator for this effort. "We've also been part of a multi-lab collaboration focused on advancing composite materials and coatings for marine energy applications."

The typical wind turbine blade in the field today is made with traditional composite materials, such as fiberglass infused with an epoxy thermoset resin.

Because this approach is energy-intensive, costly, and nonrecyclable, NREL has been experimenting with groundbreaking thermoplastic resins.

Thermoplastic composites hold the potential for enabling lighter-weight and lower-cost blades that can be recycled at the end of their lifetimes.

"We saw an opportunity to combine the strengths of additive manufacturing with advanced composite materials for more efficient device prototyping," Murdy said. "By applying this new approach to create a small-scale tidal turbine blade, we could apply our knowledge of wind system manufacturing in a new way."

Previously, the NREL-led team had applied large 3D-printed external wind blade molds produced by Oak Ridge National Laboratory to manufacture a thermoplastic wind turbine blade.

For the Seedling project, the researchers flipped the script to create additively manufactured internal molds that could become a permanent part of the final load-bearing structure.

Though other industries have regularly used internal molds for composite manufacturing, they are rarely left as part of the final structure.

And this approach had not yet been demonstrated in the renewable energy industry.

"The main benefit of additive manufacturing is that it allows for a much more creative design space," Murdy said. "Because we weren't limited by geometries like we would be with a subtractive manufacturing process, we were able to implement significant innovations to reduce the number of composite manufacturing steps involved."

The team demonstrated unique design features that could lead to improvements in manufacturability, blade strength, reliability, and continuity, such as integrated fasteners and resin passageways.

While traditional blades comprise two or more parts that are bonded together, the Seedling project allowed the researchers to experiment with a continuous composite construction.

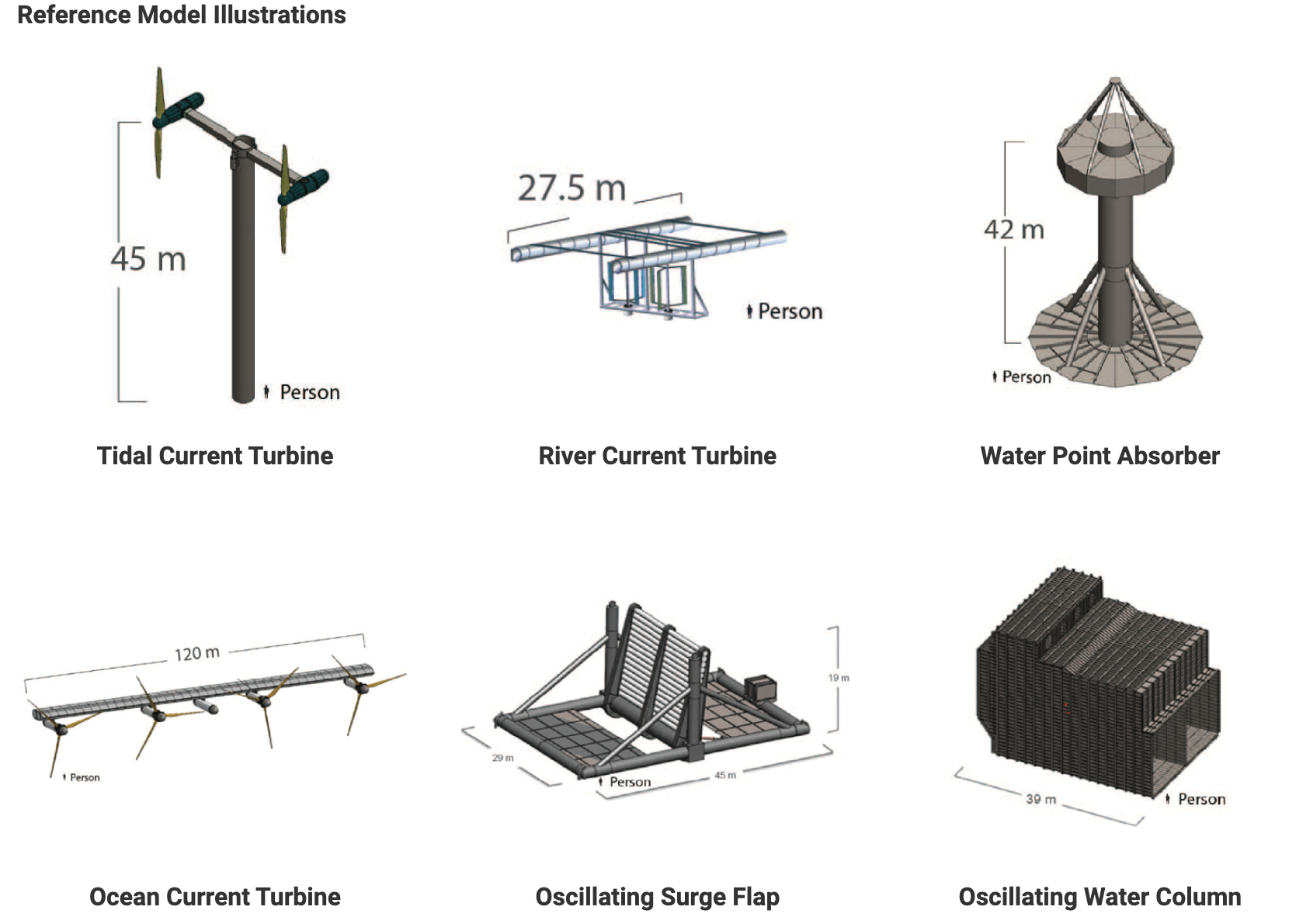

They printed the tidal turbine blade mold in four sections and then wrapped composite plies around them to remove any discontinuities and eliminate common points of failure.

Assembly drawings of the blade section mold, including the fully assembled version at top, an exploded version to show the connections between sections in the middle, and a finished version with the composite overlay below. Image from Paul Murdy, NREL

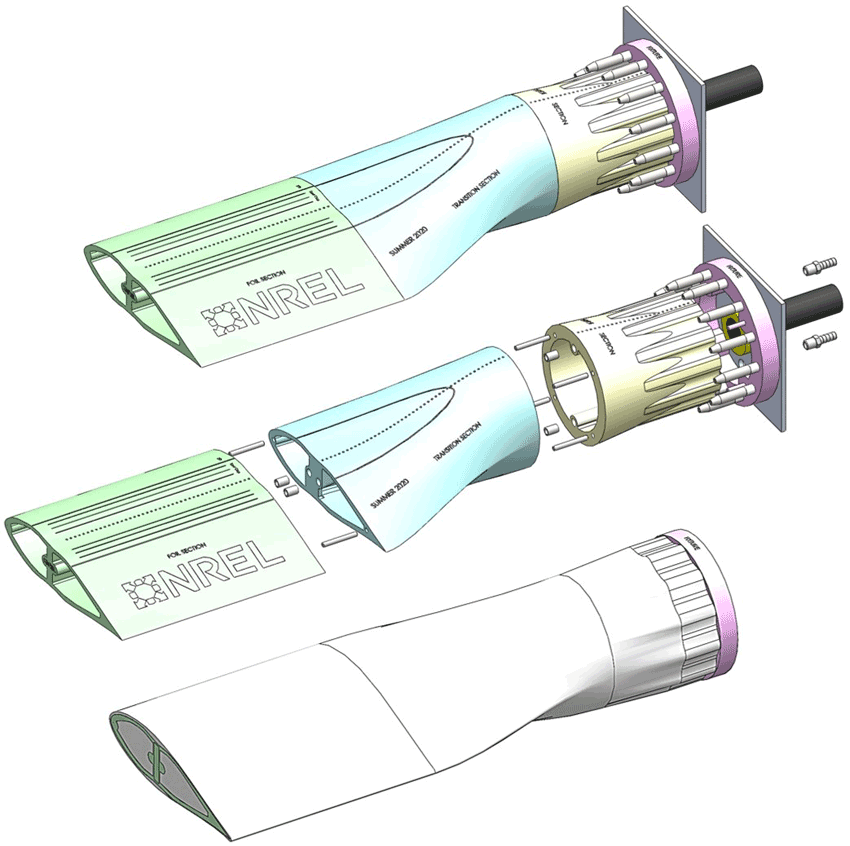

Though it is small in size, the reduced-scale additively manufactured composite tidal turbine blade section that Murdy and team produced shows significant promise for the marine energy community.

The Seedling project identified several opportunities to improve the tidal turbine blade manufacturing process, including single-piece construction and embedded root fasteners.

Most significantly, the researchers were able to demonstrate that additively manufactured composite molds can serve as part of the final load-bearing structure.

The team recently published their findings in a journal article titled "Leveraging the Advantages of Additive Manufacturing to Produce Advanced Hybrid Composite Structures for Marine Energy Systems."

The 3D-printed mold sections after being sanded and sealed with epoxy and fully assembled (front) and finished (rear). Image from Paul Murdy, NREL

"This portion of our preliminary research focused on the manufacturing side of things, so we optimized the blade section for the manufacturing process, but not structurally or hydrodynamically," Murdy said. "Our next step is to take a deeper look into the potential for structural optimization of 3D printing and composite overlays at the same time for a more holistic approach to a final blade design."

Though the application of these concepts to other types of marine energy devices will come further down the road, Murdy believes the timing is right to explore manufacturing opportunities for water power systems.

"This is just one example, but there are so many different devices and components out there that could benefit from this approach while companies are still going through early-stage design concepts and testing," Murdy said. "Hopefully, our work advances the effort to get more durable, recyclable, and less expensive machines in the water, quicker."