Susannah Shoemaker, NREL05.26.22

Among the National Renewable Energy Laboratory's (NREL) many funding agencies, the U.S. Department of Energy's Advanced Research Projects Agency-Energy (ARPA-E) funds what is perhaps some of NREL's most innovative work.

ARPA-E's mission is to advance promising technologies that are not yet ready for private-sector investment, with the goal of developing new ways to generate, store, and use energy. The high-risk, high-reward nature of these projects is what makes them so exciting—and what requires NREL researchers to use their most creative problem-solving approaches.

This year, ARPA-E-funded projects will be showcased at the 12th annual ARPA-E Energy Innovation Summit, to be held on May 23–25 in Denver, CO. In the lead-up to the summit, NREL researchers are reflecting on the ways in which ARPA-E funding has allowed them to advance innovative research and develop robust industry partnerships.

Since 2009, ARPA-E has provided approximately $2.93 billion in R&D funding for more than 1,270 potentially transformational energy technology projects. NREL has played a key role in many of these projects, ranging from developing new solar cell material growth techniques and improving grid control to reducing energy use in transportation. In the five ARPA-E projects featured here, NREL's collaborative, partnership-oriented approach has been crucial.

"ARPA-E proposals are among the most cross-cutting, innovative technologies. That's what makes them so exciting," said Kirstin Alberi, who serves as the ARPA-E point of contact for NREL. "[The projects below] represent the many ways NREL is partnering with industry to advance disruptive technologies."

Energy Storage Technology Heats Up

NREL’s ARPA-E ENDURING project is aimed at developing low-cost long-duration thermal energy storage. Illustration by Jeffrey Gifford and Patrick Davenport, NRELPrincipal Investigator Zhiwen Ma and his team are in the final stages of their ARPA-E project, ENDURING (Economic Long-Duration Electricity Storage by Using Low-Cost Thermal Energy Storage and High-Efficiency Power Cycle), aimed at developing a new, low-cost technology for long-duration thermal energy storage. This technology is poised to have far-reaching impacts; it has applications in transportation and industry, and it ultimately aims to compete with natural gas.

The idea for the project originated over a decade ago. "At first, everyone challenged this method of converting electricity back to heat," said Ma, who is a senior mechanical engineering researcher. But with the electrification of the energy sector and more abundant renewable electricity becoming available, thermal energy began to make more and more sense in the broad decarbonization of the economy.

"Our technology focuses on using low-cost silica sand to provide broad application potentials for integrating renewable generation," Ma said. "This is in contrast to molten salt energy storage, which is challenging because it freezes at low temperatures and can decompose at high temperatures."

Ma and his team persevered, and in 2018, the project received nearly $2.8 million in funding over three years from ARPA-E.

The ENDURING technology works by heating stable, low-cost solid silica particles—which, unlike molten salts, are stable at both high and ambient temperatures—to over 1,000 degrees Celsius. This charging process happens when electric power is cheapest, allowing the resulting energy to be stored for several days in large storage modules. To discharge this energy, the hot particles are fed through a heat exchanger, ultimately driving an electric generator.

This type of long-duration stationary energy storage is key to improving the resiliency of the grid, integrating more intermittent renewable energy resources such as wind and solar, and improving these renewable resources' reliability.

And now, this technology is becoming a reality.

"The project is wrapping up this spring, and we're now looking to get it out of lab scale and into pilot scale," Ma said. "We have received some follow-up funding, and the potential next step is to develop a pilot facility with our industry partners in a site adjacent to NREL's Flatirons Campus."

Industry partnership has been crucial throughout the project and is perhaps one of the most exciting aspects of the work.

"We're helping a traditional coal company move into a new energy area, and they're very excited about that," Ma said. "Our partnership is helping them to reshape their vision and get into things that will blossom in the next 10, 15, 20 years."

Drilling Down into Next-Generation Energy Resources

Geothermal energy is a vast, untapped source of clean electricity. Photo from San Federico, Geothermal Resources Council Photo Contest 2019Jody Robins and his team are utilizing ARPA-E funding to tap into a vast, untapped source of clean electricity—geothermal energy. Geothermal rock is harder, higher-temperature, and less porous than the rock typically found in oil and gas wells, making drilling more difficult and expensive.

Their project, RePED 250: A Revolutionary, High-Drilling Rate, High-T Geothermal Drilling System and Companion (250°–350°C) Power Electronics, aims to change that by increasing drilling speeds and reducing costs.

The ultimate goal is to enable drilling of engineered geothermal system (EGS)-type wells, which offer significant potential for expanding geothermal energy.

"EGS is geothermal that can be drilled anywhere—it would mean that geothermal would no longer be limited to the western United States," said Robins, a senior geothermal engineer at NREL. "For the geothermal industry, it would be a massive change, and it would be an always-on complement to solar and wind."

The team received nearly $5 million in ARPA-E funding in September 2019 (the initial application was developed by Kate Young, and Robins joined the project after the application had been submitted).

"The technology is risky, so ARPA-E was the logical place to go for funding," Robins said.

Apart from some supply-chain delays, the project has been progressing rapidly, with some pleasant surprises along the way. "We thought there would be significant redesign necessary to drill through granite, because it's so much harder and lower porosity. It was a big surprise, but a welcome one, to find out that this wasn't necessary."

As with NREL's other ARPA-E projects, industry collaboration is a key focus.

"Most of the competing methods require huge changes to the drilling rigs at the surface," Robins said. "This one doesn't. For people used to drilling, not much will change. If we're successful, there's a good chance [industry] will try it out. Commercialization is always the question, and we've got a good shot at it being widely deployed."

Devon Kesseli, a researcher in the Thermal Energy Science and Technologies Group at NREL, is now poised to lead this project in its next steps.

Enabling Fast Growth and Low Costs for Multijunction Solar Cells

III-V semiconductors are the best available for many telecommunications, solar energy, and electronics applications. But high costs and low production volumes have long constrained the growth of this technology. For example, III-V solar cell manufacturing is measured in kilowatts per year (compared to gigawatts per year for silicon solar cells).

Led by senior scientist Aaron Ptak, NREL and industry partners are developing the dynamic hydride vapor phase epitaxy (D-HVPE) process to enable the mass production of III-V semiconductors. Like many great inventions, D-HVPE is the result of re-envisioning a persistent problem as an opportunity. HVPE was one of the first processes used to grow III-V semiconductors, but it was mostly abandoned because its fast growth made it difficult to control and form abrupt interfaces.

"Everyone recognized in decades past that HVPE was a great technique for growing really high-quality materials, but it wasn't super useful. You couldn't use it to make complex device structures like transistors or lasers or high-efficiency solar cells. Our challenge was to figure out how to make HVPE useful for these applications," Ptak said.

The D-HVPE team at NREL turned HVPE's fast growth to an advantage by developing a reactor with multiple chambers, allowing the team to abruptly change which elements are growing on the crystal. Not only does this enable cheaper, faster growth, but it perfectly sets the stage for a transition to high-throughput, in-line production.

ARPA-E funding was a critical in developing this innovation. The ARPA-E High-Efficiency PV Cells project funding period is now over, but the demonstration of using HPVE to grow high-efficiency PV cells was important because it helped to test a use case for HPVE.

"ARPA-E support was critical for us," Ptak said. "Not only did it allow us to understand and refine the technology, but ARPA-E's focus on tech-to-market activities allowed us to go out and talk to people and show that, if successful, people in the real world would care about what we're doing."

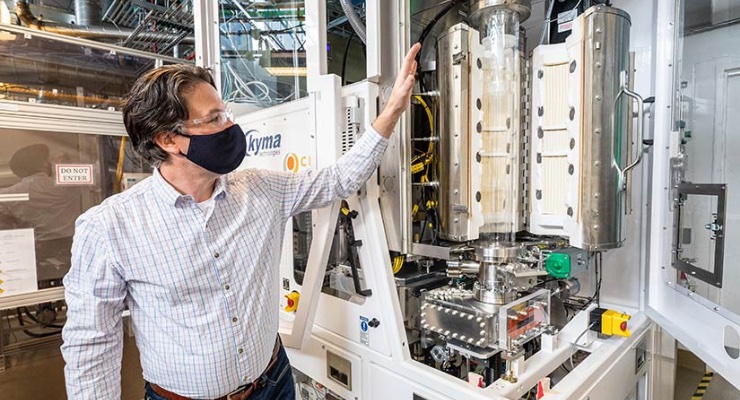

NREL is now working with several industry partners to commercialize the D-HVPE process for III-V solar cells. Kyma Technologies, a U.S.-based small business and producer of HVPE equipment for other materials, was competitively selected to work with NREL to design a pilot-scale production line. Ceres, another U.S. small business, is partnered with Kyma to construct the pilot line. Kyma and Ceres will host a factory acceptance test of the pilot reactor in May 2022 in anticipation of a delivery to NREL in July.

Bringing Floating Offshore Wind Design into Deeper Waters

Optimizing new wind energy technologies and reducing the cost of wind energy are critical to meeting the United States' ambitious decarbonization goals—in particular, the Biden administration's 30 GW by 2030 goal for offshore wind. To further that effort, Alan Wright and his team at NREL are developing a new toolset, called Wind Energy With Integrated Servo-Control (WEIS), to optimize the design of both conventional and novel floating offshore wind turbines. This toolset uses a technique called control co-design to achieve reduced costs and improved designs.

"In systems design, things are done sequentially—maybe the rotor is designed first, then the drivetrain, then the generator, then the platform, and so on. The objective of control co-design is to do all of that concurrently," said Wright, a control engineering researcher at NREL and principal investigator of the WEIS project. "Optimizing the components, including the controller, together allows you to realize cost reductions and lighter, more flexible components."

With $2.7 million in ARPA-E funding, Wright and his team—including co-PIs Garrett Barter, Jason Jonkman, Matthew Hall, Dan Zalkind, and John Jasa at NREL; James Allison at the University of Illinois Urbana-Champaign; and Daniel Herber at Colorado State University—are working to demonstrate the toolset's capabilities to ready it for industry use.

To ensure that the toolset will have a real-world impact, the team has set up an external advisory board with members from General Electric, Glosten, Siemens, Shell, the University of Maine, and other industry, university, and national laboratory partners.

"The collaborations have been a big emphasis. We're not just developing a toolset, but also trying to help industry develop lighter, lower-cost floating offshore wind turbines," Wright said. "Getting the toolset into our industry partners' hands is a big goal of the project."

The open-source tool is publicly accessible and flexible enough to allow users to incorporate their own models and inputs.

"One of the most exciting parts of the project thus far is that we've recently demonstrated the toolset on a few benchmark case studies," Wright said. "Two years isn't a lot of time to start from scratch and develop a big toolset, but we've done that and realized very positive results."

Electrification Takes Flight

Sreekant Narumanchi—senior researcher and manager of the Advanced Power Electronics and Electric Machines (APEEM) Group within the Center for Integrated Mobility Sciences at NREL—and his group are involved in no less than seven ARPA-E projects at NREL. These projects are focused on power electronics, electric machines, and thermal management, but there is also another common theme: collaboration.

"When a new opportunity comes along, we're very proactive about reaching out to our network to say, 'Hey, let's team up,'" Narumanchi said. "Our group has been very excited about the collaborations we've developed."

One of these collaborative projects, led by General Electric (GE), focuses on power electronics, electric machines, and thermal management for the electrification of aviation. The team is developing an ultrahigh-efficiency aircraft propulsion system to reduce aviation-related greenhouse gas emissions, and Narumanchi's group in particular is focusing on developing an integrated electric drive for the hybrid electric aircraft of the future. Ultimately, GE plans to develop a 2-MW, fully integrated all-electric aircraft powertrain and demonstrate a 350-kW lab-scale prototype.

"ARPA-E has proven itself to be a pioneer in many areas, and the project with GE is a good example," Narumanchi said. "This is one of the first DOE-funded programs related to electrified components in the context of aviation. ARPA-E likes to use the word 'transformational,' and they do walk that talk."

In addition to the GE project, Narumanchi's group is involved in six other projects, ranging from exploring the limits of cooling for extreme heat flux applications (in collaboration with Stanford University) to developing power electronics for fusion applications (in collaboration with Princeton Fusion Systems).

Because ARPA-E funds projects that are not yet ready for private sector investment, these projects help foster early-stage collaboration, setting the stage for fruitful partnerships later on. Industry partnerships not only bring valuable capabilities and expertise to NREL's research, but also allow NREL to add value to projects led by industry.

"Our group—and this is true in general at NREL—is always on the lookout for collaborations, partnerships, and opportunities," Narumanchi said. "Over the years, we've presented to colleagues at DOE meetings, presented at other meetings, and have participated in conferences and advisory boards. That exposure has expanded our spectrum of collaborators. It's very much a cumulative process."

ARPA-E's mission is to advance promising technologies that are not yet ready for private-sector investment, with the goal of developing new ways to generate, store, and use energy. The high-risk, high-reward nature of these projects is what makes them so exciting—and what requires NREL researchers to use their most creative problem-solving approaches.

This year, ARPA-E-funded projects will be showcased at the 12th annual ARPA-E Energy Innovation Summit, to be held on May 23–25 in Denver, CO. In the lead-up to the summit, NREL researchers are reflecting on the ways in which ARPA-E funding has allowed them to advance innovative research and develop robust industry partnerships.

Since 2009, ARPA-E has provided approximately $2.93 billion in R&D funding for more than 1,270 potentially transformational energy technology projects. NREL has played a key role in many of these projects, ranging from developing new solar cell material growth techniques and improving grid control to reducing energy use in transportation. In the five ARPA-E projects featured here, NREL's collaborative, partnership-oriented approach has been crucial.

"ARPA-E proposals are among the most cross-cutting, innovative technologies. That's what makes them so exciting," said Kirstin Alberi, who serves as the ARPA-E point of contact for NREL. "[The projects below] represent the many ways NREL is partnering with industry to advance disruptive technologies."

Energy Storage Technology Heats Up

NREL’s ARPA-E ENDURING project is aimed at developing low-cost long-duration thermal energy storage. Illustration by Jeffrey Gifford and Patrick Davenport, NRELPrincipal Investigator Zhiwen Ma and his team are in the final stages of their ARPA-E project, ENDURING (Economic Long-Duration Electricity Storage by Using Low-Cost Thermal Energy Storage and High-Efficiency Power Cycle), aimed at developing a new, low-cost technology for long-duration thermal energy storage. This technology is poised to have far-reaching impacts; it has applications in transportation and industry, and it ultimately aims to compete with natural gas.

The idea for the project originated over a decade ago. "At first, everyone challenged this method of converting electricity back to heat," said Ma, who is a senior mechanical engineering researcher. But with the electrification of the energy sector and more abundant renewable electricity becoming available, thermal energy began to make more and more sense in the broad decarbonization of the economy.

"Our technology focuses on using low-cost silica sand to provide broad application potentials for integrating renewable generation," Ma said. "This is in contrast to molten salt energy storage, which is challenging because it freezes at low temperatures and can decompose at high temperatures."

Ma and his team persevered, and in 2018, the project received nearly $2.8 million in funding over three years from ARPA-E.

The ENDURING technology works by heating stable, low-cost solid silica particles—which, unlike molten salts, are stable at both high and ambient temperatures—to over 1,000 degrees Celsius. This charging process happens when electric power is cheapest, allowing the resulting energy to be stored for several days in large storage modules. To discharge this energy, the hot particles are fed through a heat exchanger, ultimately driving an electric generator.

This type of long-duration stationary energy storage is key to improving the resiliency of the grid, integrating more intermittent renewable energy resources such as wind and solar, and improving these renewable resources' reliability.

And now, this technology is becoming a reality.

"The project is wrapping up this spring, and we're now looking to get it out of lab scale and into pilot scale," Ma said. "We have received some follow-up funding, and the potential next step is to develop a pilot facility with our industry partners in a site adjacent to NREL's Flatirons Campus."

Industry partnership has been crucial throughout the project and is perhaps one of the most exciting aspects of the work.

"We're helping a traditional coal company move into a new energy area, and they're very excited about that," Ma said. "Our partnership is helping them to reshape their vision and get into things that will blossom in the next 10, 15, 20 years."

Drilling Down into Next-Generation Energy Resources

Geothermal energy is a vast, untapped source of clean electricity. Photo from San Federico, Geothermal Resources Council Photo Contest 2019Jody Robins and his team are utilizing ARPA-E funding to tap into a vast, untapped source of clean electricity—geothermal energy. Geothermal rock is harder, higher-temperature, and less porous than the rock typically found in oil and gas wells, making drilling more difficult and expensive.

Their project, RePED 250: A Revolutionary, High-Drilling Rate, High-T Geothermal Drilling System and Companion (250°–350°C) Power Electronics, aims to change that by increasing drilling speeds and reducing costs.

The ultimate goal is to enable drilling of engineered geothermal system (EGS)-type wells, which offer significant potential for expanding geothermal energy.

"EGS is geothermal that can be drilled anywhere—it would mean that geothermal would no longer be limited to the western United States," said Robins, a senior geothermal engineer at NREL. "For the geothermal industry, it would be a massive change, and it would be an always-on complement to solar and wind."

The team received nearly $5 million in ARPA-E funding in September 2019 (the initial application was developed by Kate Young, and Robins joined the project after the application had been submitted).

"The technology is risky, so ARPA-E was the logical place to go for funding," Robins said.

Apart from some supply-chain delays, the project has been progressing rapidly, with some pleasant surprises along the way. "We thought there would be significant redesign necessary to drill through granite, because it's so much harder and lower porosity. It was a big surprise, but a welcome one, to find out that this wasn't necessary."

As with NREL's other ARPA-E projects, industry collaboration is a key focus.

"Most of the competing methods require huge changes to the drilling rigs at the surface," Robins said. "This one doesn't. For people used to drilling, not much will change. If we're successful, there's a good chance [industry] will try it out. Commercialization is always the question, and we've got a good shot at it being widely deployed."

Devon Kesseli, a researcher in the Thermal Energy Science and Technologies Group at NREL, is now poised to lead this project in its next steps.

Enabling Fast Growth and Low Costs for Multijunction Solar Cells

III-V semiconductors are the best available for many telecommunications, solar energy, and electronics applications. But high costs and low production volumes have long constrained the growth of this technology. For example, III-V solar cell manufacturing is measured in kilowatts per year (compared to gigawatts per year for silicon solar cells).

Led by senior scientist Aaron Ptak, NREL and industry partners are developing the dynamic hydride vapor phase epitaxy (D-HVPE) process to enable the mass production of III-V semiconductors. Like many great inventions, D-HVPE is the result of re-envisioning a persistent problem as an opportunity. HVPE was one of the first processes used to grow III-V semiconductors, but it was mostly abandoned because its fast growth made it difficult to control and form abrupt interfaces.

"Everyone recognized in decades past that HVPE was a great technique for growing really high-quality materials, but it wasn't super useful. You couldn't use it to make complex device structures like transistors or lasers or high-efficiency solar cells. Our challenge was to figure out how to make HVPE useful for these applications," Ptak said.

The D-HVPE team at NREL turned HVPE's fast growth to an advantage by developing a reactor with multiple chambers, allowing the team to abruptly change which elements are growing on the crystal. Not only does this enable cheaper, faster growth, but it perfectly sets the stage for a transition to high-throughput, in-line production.

ARPA-E funding was a critical in developing this innovation. The ARPA-E High-Efficiency PV Cells project funding period is now over, but the demonstration of using HPVE to grow high-efficiency PV cells was important because it helped to test a use case for HPVE.

"ARPA-E support was critical for us," Ptak said. "Not only did it allow us to understand and refine the technology, but ARPA-E's focus on tech-to-market activities allowed us to go out and talk to people and show that, if successful, people in the real world would care about what we're doing."

NREL is now working with several industry partners to commercialize the D-HVPE process for III-V solar cells. Kyma Technologies, a U.S.-based small business and producer of HVPE equipment for other materials, was competitively selected to work with NREL to design a pilot-scale production line. Ceres, another U.S. small business, is partnered with Kyma to construct the pilot line. Kyma and Ceres will host a factory acceptance test of the pilot reactor in May 2022 in anticipation of a delivery to NREL in July.

Bringing Floating Offshore Wind Design into Deeper Waters

Optimizing new wind energy technologies and reducing the cost of wind energy are critical to meeting the United States' ambitious decarbonization goals—in particular, the Biden administration's 30 GW by 2030 goal for offshore wind. To further that effort, Alan Wright and his team at NREL are developing a new toolset, called Wind Energy With Integrated Servo-Control (WEIS), to optimize the design of both conventional and novel floating offshore wind turbines. This toolset uses a technique called control co-design to achieve reduced costs and improved designs.

"In systems design, things are done sequentially—maybe the rotor is designed first, then the drivetrain, then the generator, then the platform, and so on. The objective of control co-design is to do all of that concurrently," said Wright, a control engineering researcher at NREL and principal investigator of the WEIS project. "Optimizing the components, including the controller, together allows you to realize cost reductions and lighter, more flexible components."

With $2.7 million in ARPA-E funding, Wright and his team—including co-PIs Garrett Barter, Jason Jonkman, Matthew Hall, Dan Zalkind, and John Jasa at NREL; James Allison at the University of Illinois Urbana-Champaign; and Daniel Herber at Colorado State University—are working to demonstrate the toolset's capabilities to ready it for industry use.

To ensure that the toolset will have a real-world impact, the team has set up an external advisory board with members from General Electric, Glosten, Siemens, Shell, the University of Maine, and other industry, university, and national laboratory partners.

"The collaborations have been a big emphasis. We're not just developing a toolset, but also trying to help industry develop lighter, lower-cost floating offshore wind turbines," Wright said. "Getting the toolset into our industry partners' hands is a big goal of the project."

The open-source tool is publicly accessible and flexible enough to allow users to incorporate their own models and inputs.

"One of the most exciting parts of the project thus far is that we've recently demonstrated the toolset on a few benchmark case studies," Wright said. "Two years isn't a lot of time to start from scratch and develop a big toolset, but we've done that and realized very positive results."

Electrification Takes Flight

Sreekant Narumanchi—senior researcher and manager of the Advanced Power Electronics and Electric Machines (APEEM) Group within the Center for Integrated Mobility Sciences at NREL—and his group are involved in no less than seven ARPA-E projects at NREL. These projects are focused on power electronics, electric machines, and thermal management, but there is also another common theme: collaboration.

"When a new opportunity comes along, we're very proactive about reaching out to our network to say, 'Hey, let's team up,'" Narumanchi said. "Our group has been very excited about the collaborations we've developed."

One of these collaborative projects, led by General Electric (GE), focuses on power electronics, electric machines, and thermal management for the electrification of aviation. The team is developing an ultrahigh-efficiency aircraft propulsion system to reduce aviation-related greenhouse gas emissions, and Narumanchi's group in particular is focusing on developing an integrated electric drive for the hybrid electric aircraft of the future. Ultimately, GE plans to develop a 2-MW, fully integrated all-electric aircraft powertrain and demonstrate a 350-kW lab-scale prototype.

"ARPA-E has proven itself to be a pioneer in many areas, and the project with GE is a good example," Narumanchi said. "This is one of the first DOE-funded programs related to electrified components in the context of aviation. ARPA-E likes to use the word 'transformational,' and they do walk that talk."

In addition to the GE project, Narumanchi's group is involved in six other projects, ranging from exploring the limits of cooling for extreme heat flux applications (in collaboration with Stanford University) to developing power electronics for fusion applications (in collaboration with Princeton Fusion Systems).

Because ARPA-E funds projects that are not yet ready for private sector investment, these projects help foster early-stage collaboration, setting the stage for fruitful partnerships later on. Industry partnerships not only bring valuable capabilities and expertise to NREL's research, but also allow NREL to add value to projects led by industry.

"Our group—and this is true in general at NREL—is always on the lookout for collaborations, partnerships, and opportunities," Narumanchi said. "Over the years, we've presented to colleagues at DOE meetings, presented at other meetings, and have participated in conferences and advisory boards. That exposure has expanded our spectrum of collaborators. It's very much a cumulative process."