David Savastano, Editor04.15.15

Flexible and printed electronics are finding new opportunities in numerous fields, including automotive seat heaters, biosensors, keyboards and touch screens and more. For Henkel Electronic Materials, these fields provide excellent opportunities for its conductive ink and coating technologies.

Henkel Electronic Materials was formed in 2008, when Henkel acquired the National Starch Adhesives group, including Acheson Printed Inks. Today, Henkel offers conductive, dielectric and thick film functional inks and coatings for a wide range of applications. These inks and coatings can be printed by screen, flexo and gravure on flexible or rigid substrates, and can be dried or cured through heat or UV curing.

Henkel’s conductive inks and coatings are found in numerous applications, including flexible circuits for membrane touch switches, desktop and notebook keyboards, touch screens, heating elements, automotive sensors, biosensors, EKG/ECG electrodes, antennas for contactless smart cards and RFID labels, electroluminescent lamps and printed circuit boards.

Doug Dixon, global marketing director for Henkel Electronic Materials LLC, noted that flexible electronics is a growth area for Henkel.

“Flexible electronics is a growing industry, one of the areas Henkel has been investing,” said Dixon. “Flexible displays will be one of the major drivers going forward, specifically touch screen displays, and mobile devices have driven touch screens. The big question still not known is wearable electronics. This market is still developing.”

Henkel uses a variety of materials for its conductive inks, including silver and silver/silver chloride (its water-based ACHESON and ELECTRODAG screen ink lines); carbon (ELECTRODAG inks for membrane touch switches and printed circuit boards); and dielectric inks (ELECTRODAG and MINICO screen ink lines for keyboards and hybrid circuits).

“Henkel has a complete line of printed inks, non-conductive, conductive, protective layering designed for the flexible electronics markets” Dixon said. “We also have a full product offering for electronic assembly and semiconductor assembly materials.”

Dixon noted that the company is having strong success with its PTC Ink series.

“We developed materials that heat up to specific temperatures and then stop heating,” he said. “This is a major breakthrough in the industry. Currently the PTC inks are being used for automotive heated seats, but this could easily go into other markets as well.”

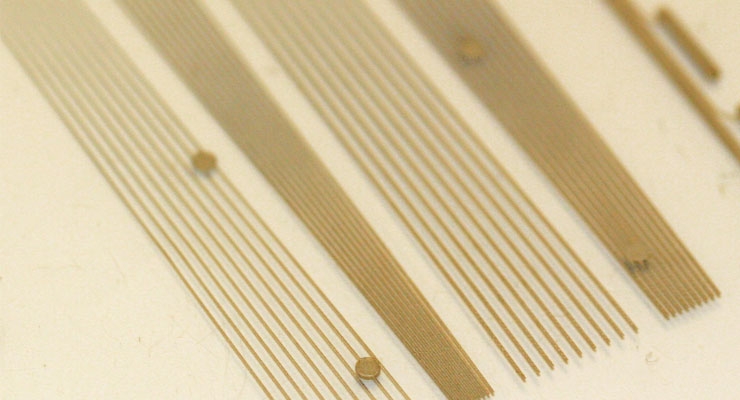

Fine Line inks are another growth area for Henkel.

“We are continuing to develop materials that are able to be printed to fine pitch applications with improved ability to bend and flex,” Dixon noted.

One key to Henkel’s growth in flexible electronics is its focus on innovation.

“Henkel is approaching the printed ink market with a strategy of innovation,” Dixon added. “We want to be the innovation leaders in this market.

Dixon anticipates “aggressive growth” for flexible electronics.

“We think that there are a number of opportunities for growth in the printed inks market.,” Dixon concluded. “Henkel’s significant investments in this technology, pulling from our knowledge in adhesives and technology, will help enable new applications, like our PTC inks for heating car seats.”

Henkel Electronic Materials was formed in 2008, when Henkel acquired the National Starch Adhesives group, including Acheson Printed Inks. Today, Henkel offers conductive, dielectric and thick film functional inks and coatings for a wide range of applications. These inks and coatings can be printed by screen, flexo and gravure on flexible or rigid substrates, and can be dried or cured through heat or UV curing.

Henkel’s conductive inks and coatings are found in numerous applications, including flexible circuits for membrane touch switches, desktop and notebook keyboards, touch screens, heating elements, automotive sensors, biosensors, EKG/ECG electrodes, antennas for contactless smart cards and RFID labels, electroluminescent lamps and printed circuit boards.

Doug Dixon, global marketing director for Henkel Electronic Materials LLC, noted that flexible electronics is a growth area for Henkel.

“Flexible electronics is a growing industry, one of the areas Henkel has been investing,” said Dixon. “Flexible displays will be one of the major drivers going forward, specifically touch screen displays, and mobile devices have driven touch screens. The big question still not known is wearable electronics. This market is still developing.”

Henkel uses a variety of materials for its conductive inks, including silver and silver/silver chloride (its water-based ACHESON and ELECTRODAG screen ink lines); carbon (ELECTRODAG inks for membrane touch switches and printed circuit boards); and dielectric inks (ELECTRODAG and MINICO screen ink lines for keyboards and hybrid circuits).

“Henkel has a complete line of printed inks, non-conductive, conductive, protective layering designed for the flexible electronics markets” Dixon said. “We also have a full product offering for electronic assembly and semiconductor assembly materials.”

Dixon noted that the company is having strong success with its PTC Ink series.

“We developed materials that heat up to specific temperatures and then stop heating,” he said. “This is a major breakthrough in the industry. Currently the PTC inks are being used for automotive heated seats, but this could easily go into other markets as well.”

Fine Line inks are another growth area for Henkel.

“We are continuing to develop materials that are able to be printed to fine pitch applications with improved ability to bend and flex,” Dixon noted.

One key to Henkel’s growth in flexible electronics is its focus on innovation.

“Henkel is approaching the printed ink market with a strategy of innovation,” Dixon added. “We want to be the innovation leaders in this market.

Dixon anticipates “aggressive growth” for flexible electronics.

“We think that there are a number of opportunities for growth in the printed inks market.,” Dixon concluded. “Henkel’s significant investments in this technology, pulling from our knowledge in adhesives and technology, will help enable new applications, like our PTC inks for heating car seats.”