David Savastano, Editor08.03.16

The world of 3D printing holds so much promise for many industries, and there are new technologies that are improving the 3D printing process. Through its Continuous Scaled Manufacturing process, Continuous Composites (CC3D), located in Coeur d’Alene, ID, is helping to move the technology ahead.

Continuous Scaled Manufacturing is a new 3D printing process that prints continuous fiber with UV thermoset resin. As a result, Continuous Composites received the Emerging Innovation Award at RadTech’s 2016 UV/EB Conference in Chicago.

From its first provisional patent for Continuous Composite Three Dimensional filed in August 2012 to today, Continuous Composites is creating strong, functional, lightweight parts at a lower cost and at greater speed. Two years ago, the company pioneered its AMG (additive mechanical growth) concept, which utilizes tubular printing techniques to digitally produce advanced structures with potentially unlimited size and shape. CC3D’s continuous scaled manufacturing process has the potential to produce 3D printed objects at speeds of up to 1,200 inch/min. The goal at CC3D is to license its technology to a variety of industries and revolutionize composite manufacturing.

History of Continuous Composites

Continuous Composites founder and inventor Ken Tyler was building boats when he came up with the idea of 3D printing continuous fiber in 2012. Ken had some experience with traditional methods of 3D printing and thought there had to be a better way than melting plastic together. When working on boats, Ken accidently stabbed himself with a single strand of fiberglass from a layup that had cured overnight, and the idea was born He filed his first patent in the summer of 2012, using fast curing UV thermoset resins and continuous fibers.

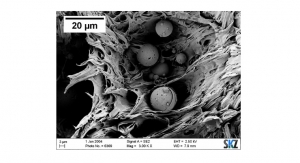

By November 2012, the first prototype was built to prove the technology. Ken continued to focus on proving out the technology and filing additional patents around the technology. A few years into the venture, the owners of McAllister Technical Services joined forces with Ken making an investment and creating a strategic relationship between McAllister and CC3D in July 2015. In March of 2016, CC3D demonstrated printing with functional materials such as continuous copper wire .01 gauge and fiber optics To date, CC3D has demonstrated its ability to print with single channel and multi-channel nozzles using the following materials: carbon fiber, fiber glass, fiber optics, copper wire and Kevlar.

Advantages of CC3D’s Technology

Continuous Composites’ 3D printing technology offers numerous advantages, beginning with the ability to print functional, strong materials for its core, including fiber optics, carbon fiber, metal wire, thermoset resin and polymer encasement.

“Demonstrating a new approach to 3D printing, we have developed a Continuously Scaled Manufacturing solution focused on printing functional, strong and lightweight materials,” Tyler reported. “In addition, our patent pending AMG Technology provides a foundational new positioning system utilizing hollow tubular printing techniques and multiple print heads working together in tandem to continuously manufacture large advanced structures.”

Tyler said that CC3D’s core technology developments harness UV light to instantly cure the company’s combination of continuous fiber and matrix material, giving CC3D the ability to print into free space at a rapid speed.

“Initially printing with a single nozzle, we have rapidly improved our process to print with 8 channel and 16 channel nozzles utilizing different material combinations, including novel combinations of copper wire and fiber optics,” said Tyler.

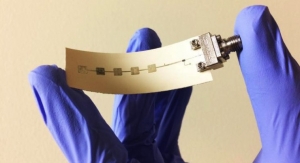

“Printing with our technology enables the ability to produce functional end use parts,” he added. “We can embed and print with continuous strands of conductive material that are capable of carrying high current. We can print with fiber optics directly in our composite parts for applications such as an active strain gauge for sensing stress or fractures across the part in real time. True 3D printing is at hand with the ability to print complex geometries and surfaces into free space, utilizing generative design software fiber is discretely oriented to counteract forces and meet the constraints of a part utilizing just the right amount of material.”

For Continuous Composites, the key differentiator is its patent-pending production approaches.

“We own cutting edge, patent-pending manufacturing processes that are poised to revolutionize the additive manufacturing industry,” said Tyler. “Utilizing this technology, we have the capability to print unique geometries, such as curves, into free space. Our process is fast, efficient and scalable. We have also developed methods of multi-material and tubular printing utilizing materials such as fiber optics, carbon fiber, Kevlar, fiberglass and copper wire. Unlike traditional additive manufacturing processes, which are restricted to a print bed, we are utilizing series of anchor points which we can use to manipulate the part from multiple points, with additional control axes.”

“Our Additive Mechanical Growth of Tubular Structures enables unlimited build volume,” he added. “With this unique process, the print head travels along the tubular path created from within for a zero form factor printing path providing a swarm bot approach to additive manufacturing. Our tubular manufacturing concepts create the ability to print a seamless tube of virtually endless length and directions.”

Tyler said that the combination of continuous fibers and UV curing leads to speeds unique in 3D printing.

“Our product is our process,” said Tyler. “By combining continuous fibers and rapidly cured proprietary thermoset resins, users are able to print exponentially faster than current industry capabilities. Our process has the potential to reach cure speeds of up to 1200 inch/min. In addition, a greater throughput of material results in an overall cubic volume output unrivaled by the traditional appliance approach of 3D printing.”

“Our curing process uses minimal energy, with the current prototype using less than 3 AMPs,” he added. “This is crucial for applications where power constraints exist. Our process also has the ability to integrate fiber optics for real-time analysis of a printed structure as well as printing flexible circuits capable of handling high current and high temperatures, reaching upwards of 300°C.”

Key Markets

Continuous Composites already sees numerous industrial opportunities, such as intelligent parts. For example, the company sees Continuous Scaled Manufacturing as an enabler for the Internet of Things IoT and integrated embedded electronics devices, through the use of multiple strands of continuous conductive material.

Other markets include boat hulls; aerospace; vehicles, motorcycles and ATVs; bike frames; data transfer and light; anti-gravity; building construction; pipelines; 3D body part printing; robotics; safety gear; automotive, defense, ballistics armor, etc.

“Composites are used in many different industries and we imagine our technology will have some application in all of them,” Tyler said. “Currently we are focused on Aerospace and Defense markets, as these industries are forward thinking with a lot of resources for R&D. Automotive, Recreational, Marine, Medical and Construction are other large industries we see our technology having a large impact.”

Tyler said that CC3D’s technology, which they term Continuous Scaled Manufacturing (CSM), offers the ability to match solutions to the problems.

“For instance, with our process, the Continuous Manufacture of Hollow Tubular Structures enables a new way to manufacture high strength composite tubes, in place, seamlessly,” Tyler noted. “There are many different iterations of our technology that are suited to different industry needs. Our goal as a company is to collaborate with industry leaders and provide them with new solutions.”

Outlook for Continuous Composites

With its proprietary CSM process and its speed and scalability, Continuous Composites is seeing new opportunities emerge with leading manufacturers.

“We are receiving significant interest from several Fortune 100 companies and are stepping through validation process,” Tyler noted.

“3D printing will shake the very groundwork of manufacturing and usher in the next industrial revolution,” he continued. “Between the advancements in metal additive manufacturing, medical bio-printing, high speed DLP, jetting process, and our functional continuous fiber composite printing, nearly every manufactured product will have the ability to be made in a new way.”

“Continuous Composites’ adaptability to scale will be unique in the industry,” Tyler concluded. “There are many aspects of our technology that make it the best choice for creating large functional parts. From an aircraft wing to a skyscraper, the world will start to see a new type of manufacturing process that will be more efficient, faster and safer.”

Continuous Scaled Manufacturing is a new 3D printing process that prints continuous fiber with UV thermoset resin. As a result, Continuous Composites received the Emerging Innovation Award at RadTech’s 2016 UV/EB Conference in Chicago.

From its first provisional patent for Continuous Composite Three Dimensional filed in August 2012 to today, Continuous Composites is creating strong, functional, lightweight parts at a lower cost and at greater speed. Two years ago, the company pioneered its AMG (additive mechanical growth) concept, which utilizes tubular printing techniques to digitally produce advanced structures with potentially unlimited size and shape. CC3D’s continuous scaled manufacturing process has the potential to produce 3D printed objects at speeds of up to 1,200 inch/min. The goal at CC3D is to license its technology to a variety of industries and revolutionize composite manufacturing.

History of Continuous Composites

Continuous Composites founder and inventor Ken Tyler was building boats when he came up with the idea of 3D printing continuous fiber in 2012. Ken had some experience with traditional methods of 3D printing and thought there had to be a better way than melting plastic together. When working on boats, Ken accidently stabbed himself with a single strand of fiberglass from a layup that had cured overnight, and the idea was born He filed his first patent in the summer of 2012, using fast curing UV thermoset resins and continuous fibers.

By November 2012, the first prototype was built to prove the technology. Ken continued to focus on proving out the technology and filing additional patents around the technology. A few years into the venture, the owners of McAllister Technical Services joined forces with Ken making an investment and creating a strategic relationship between McAllister and CC3D in July 2015. In March of 2016, CC3D demonstrated printing with functional materials such as continuous copper wire .01 gauge and fiber optics To date, CC3D has demonstrated its ability to print with single channel and multi-channel nozzles using the following materials: carbon fiber, fiber glass, fiber optics, copper wire and Kevlar.

Advantages of CC3D’s Technology

Continuous Composites’ 3D printing technology offers numerous advantages, beginning with the ability to print functional, strong materials for its core, including fiber optics, carbon fiber, metal wire, thermoset resin and polymer encasement.

“Demonstrating a new approach to 3D printing, we have developed a Continuously Scaled Manufacturing solution focused on printing functional, strong and lightweight materials,” Tyler reported. “In addition, our patent pending AMG Technology provides a foundational new positioning system utilizing hollow tubular printing techniques and multiple print heads working together in tandem to continuously manufacture large advanced structures.”

Tyler said that CC3D’s core technology developments harness UV light to instantly cure the company’s combination of continuous fiber and matrix material, giving CC3D the ability to print into free space at a rapid speed.

“Initially printing with a single nozzle, we have rapidly improved our process to print with 8 channel and 16 channel nozzles utilizing different material combinations, including novel combinations of copper wire and fiber optics,” said Tyler.

“Printing with our technology enables the ability to produce functional end use parts,” he added. “We can embed and print with continuous strands of conductive material that are capable of carrying high current. We can print with fiber optics directly in our composite parts for applications such as an active strain gauge for sensing stress or fractures across the part in real time. True 3D printing is at hand with the ability to print complex geometries and surfaces into free space, utilizing generative design software fiber is discretely oriented to counteract forces and meet the constraints of a part utilizing just the right amount of material.”

For Continuous Composites, the key differentiator is its patent-pending production approaches.

“We own cutting edge, patent-pending manufacturing processes that are poised to revolutionize the additive manufacturing industry,” said Tyler. “Utilizing this technology, we have the capability to print unique geometries, such as curves, into free space. Our process is fast, efficient and scalable. We have also developed methods of multi-material and tubular printing utilizing materials such as fiber optics, carbon fiber, Kevlar, fiberglass and copper wire. Unlike traditional additive manufacturing processes, which are restricted to a print bed, we are utilizing series of anchor points which we can use to manipulate the part from multiple points, with additional control axes.”

“Our Additive Mechanical Growth of Tubular Structures enables unlimited build volume,” he added. “With this unique process, the print head travels along the tubular path created from within for a zero form factor printing path providing a swarm bot approach to additive manufacturing. Our tubular manufacturing concepts create the ability to print a seamless tube of virtually endless length and directions.”

Tyler said that the combination of continuous fibers and UV curing leads to speeds unique in 3D printing.

“Our product is our process,” said Tyler. “By combining continuous fibers and rapidly cured proprietary thermoset resins, users are able to print exponentially faster than current industry capabilities. Our process has the potential to reach cure speeds of up to 1200 inch/min. In addition, a greater throughput of material results in an overall cubic volume output unrivaled by the traditional appliance approach of 3D printing.”

“Our curing process uses minimal energy, with the current prototype using less than 3 AMPs,” he added. “This is crucial for applications where power constraints exist. Our process also has the ability to integrate fiber optics for real-time analysis of a printed structure as well as printing flexible circuits capable of handling high current and high temperatures, reaching upwards of 300°C.”

Key Markets

Continuous Composites already sees numerous industrial opportunities, such as intelligent parts. For example, the company sees Continuous Scaled Manufacturing as an enabler for the Internet of Things IoT and integrated embedded electronics devices, through the use of multiple strands of continuous conductive material.

Other markets include boat hulls; aerospace; vehicles, motorcycles and ATVs; bike frames; data transfer and light; anti-gravity; building construction; pipelines; 3D body part printing; robotics; safety gear; automotive, defense, ballistics armor, etc.

“Composites are used in many different industries and we imagine our technology will have some application in all of them,” Tyler said. “Currently we are focused on Aerospace and Defense markets, as these industries are forward thinking with a lot of resources for R&D. Automotive, Recreational, Marine, Medical and Construction are other large industries we see our technology having a large impact.”

Tyler said that CC3D’s technology, which they term Continuous Scaled Manufacturing (CSM), offers the ability to match solutions to the problems.

“For instance, with our process, the Continuous Manufacture of Hollow Tubular Structures enables a new way to manufacture high strength composite tubes, in place, seamlessly,” Tyler noted. “There are many different iterations of our technology that are suited to different industry needs. Our goal as a company is to collaborate with industry leaders and provide them with new solutions.”

Outlook for Continuous Composites

With its proprietary CSM process and its speed and scalability, Continuous Composites is seeing new opportunities emerge with leading manufacturers.

“We are receiving significant interest from several Fortune 100 companies and are stepping through validation process,” Tyler noted.

“3D printing will shake the very groundwork of manufacturing and usher in the next industrial revolution,” he continued. “Between the advancements in metal additive manufacturing, medical bio-printing, high speed DLP, jetting process, and our functional continuous fiber composite printing, nearly every manufactured product will have the ability to be made in a new way.”

“Continuous Composites’ adaptability to scale will be unique in the industry,” Tyler concluded. “There are many aspects of our technology that make it the best choice for creating large functional parts. From an aircraft wing to a skyscraper, the world will start to see a new type of manufacturing process that will be more efficient, faster and safer.”