David Savastano, Editor01.22.18

Flexible and printed electronics manufacturers made some interesting headway toward commercialization during 2017, with promising products either reaching the market or getting close.

GE and Optomec – Strain Sensors for Turbine Blades

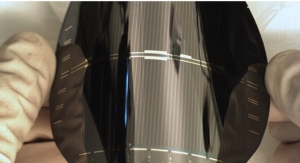

Maintaining turbine blades used in industrial gas turbines is an expensive process. General Electric (GE) now uses Optomec’s Aerosol Jet technology to print passive strain sensors made of a ceramic material directly onto the turbine blades. These sensors are used to detect fatigue and creep in the metal that could lead to costly, dangerous failures. Prior to its work with Optomec, GE would take out the blades every 7,500 hours; since Optomec started producing these sensors, GE has only had to replace one blade.

“We developed a printed strain sensor for ATVs that detected torque on the drive shaft,” said Mike O'Reilly, director, Aerosol Jet Product Management for Optomec. “It led to improved drive shaft design. We also developed a leak detector for a pipeline that replaced an ultrasound detector hose clamped onto the pipeline. We printed serialized sensors directly onto the pipeline that provided feedback on corrosion and leaks, which allowed for just-in-time maintenance.”

One of Optomec’s success stories is its printed strain sensors for General Electric’s turbine blades.

“GE would take out the blades every 7500 hours,” O’Reilly noted. “Our sensors detect fatigue and creep. The goal was to reduce maintenance, and since we started producing these sensors three years ago, GE has only had to replace one blade. They believe it has saved them $1 billion.”

Maintaining turbine blades used in industrial gas turbines is an expensive process. General Electric (GE) now uses Optomec’s Aerosol Jet technology to print passive strain sensors made of a ceramic material directly onto the turbine blades. These sensors are used to detect fatigue and creep in the metal that could lead to costly, dangerous failures. Prior to its work with Optomec, GE would take out the blades every 7,500 hours; since Optomec started producing these sensors, GE has only had to replace one blade.

“We developed a printed strain sensor for ATVs that detected torque on the drive shaft,” said Mike O'Reilly, director, Aerosol Jet Product Management for Optomec. “It led to improved drive shaft design. We also developed a leak detector for a pipeline that replaced an ultrasound detector hose clamped onto the pipeline. We printed serialized sensors directly onto the pipeline that provided feedback on corrosion and leaks, which allowed for just-in-time maintenance.”

One of Optomec’s success stories is its printed strain sensors for General Electric’s turbine blades.

“GE would take out the blades every 7500 hours,” O’Reilly noted. “Our sensors detect fatigue and creep. The goal was to reduce maintenance, and since we started producing these sensors three years ago, GE has only had to replace one blade. They believe it has saved them $1 billion.”