David Savastano, Editor02.28.18

As the market for flexible and printed electronics has grown in recent years, so have the needs for the conductive inks and other materials that help drive these devices. Industry leaders offered their insights into the changes in the requirements.

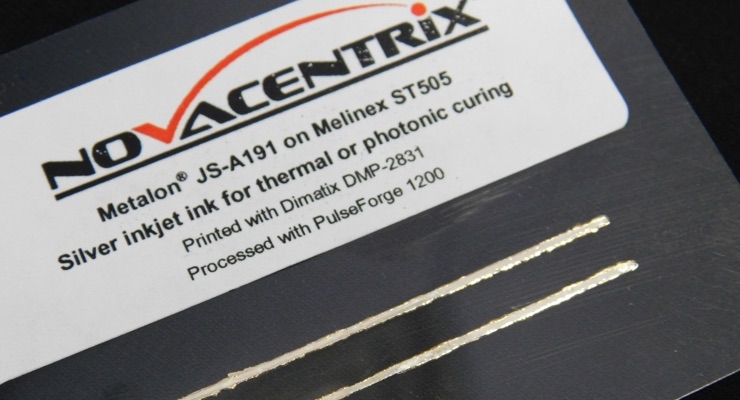

“Customers are now much more educated as far as what their ink requirements are,” said Stan Farnsworth, chief marketing officer for NovaCentrix. “Early on in the space, electrical conductivity was the paramount requirement, whereas these days clients know they also need printability and adhesion. We’ve also seen growth in interest in inkjet printing, with clients purchasing systems with integrated print/cure capabilities.”

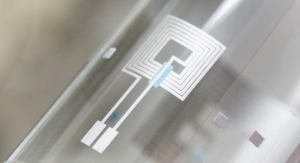

“It is clear that printed electronics manufacturers must be convinced that any innovation will enhance the device, be competitive, and have a reliable global supply infrastructure,” said Roy Bjorlin, global commercial and strategic initiatives director, Sun Chemical Advanced Materials. “This is especially true for smart packaging. For example, nanomaterials such as nanosilver could enable significant advancements in a broad range of applications, including photovoltaic and semiconductor packaging.”

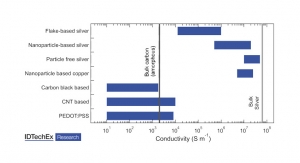

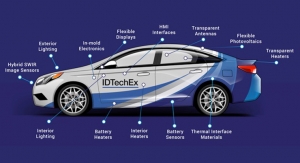

IDTechEx CEO Raghu Das reported that IDTechEx has seen conductive ink formulations focused on specific applications, with suppliers creating many appropriate specialized formulations.

“Sectors such as photovoltaics (PV) and touch screens have seen strong demand for conductive ink with continual improvements in the ink to add value to the customer, such as better particle size control, uniformity etc.,” Das noted. “One of the main drivers has been moving to narrower printed tracks while retaining conductivity. PV demands this to improve efficiencies by exposure as much of the silicon wafer to the sunlight as possible. Here there has been continual improvement in ink and manufacturing to enable this.

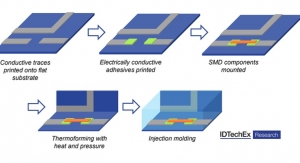

“Over the past two years, we have seen many more applications receive interest from conductive ink makers, such as e-textiles and in-mold electronic, which have driven new conductive ink formulations including stretchable conductive ink,” Das added.

“Demands on raw materials like conductive inks have increased tremendously,” said Kerry Adams, European business development manager, DuPont Advanced Materials. “The inks have to perform across a broad range of application conditions and whereas it used to be just about conductivity and fine line performance, people now demand things such as stretchability, washability and formability. Compatibility across complex multilayers is necessary as people print more and more components of their particular device.”

“The performance targets of silver nanoparticles have been consistent – high conductivity and low-temperature sintering, coupled with ink and printing stability,” said Frank Wallace, technical director at NANOGAP, Inc. “The requirement for low-cost silver nanoparticles has increased in recent years. For silver nanowires, in touch panel applications, there is an increasing requirement for low haze performance and solutions to electro-migration issues. In applications outside of touch panels, the requirement is for good performance (not necessarily low haze) at low cost.”

“In the past, the requirements were focused strictly on flexible materials now was are seeing demand on elongation properties and surviving more dynamic conditions,” said Matthew Ganslaw, VP sales for Creative Materials. “An example of the new market demands includes washable and dry-able conductive inks.”

“Conductive ink requirements have evolved,” Alan Brown, applications manager, EMS, Inc., said. “Conductive inks must now be stretched, flexed and creased many times, in order to meet the specifications in these evolving markets.”

Steve Toyama, sales manager at Applied Ink Solutions, reported that customers have more applications for stretchable, elongating inks for disposable sensors. “We also have adapted to applying conductive inks in non-conventional applications like spraying and dipping,” Toyama added.

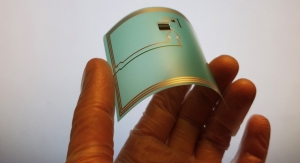

Bill Babe, Liquid-X Printed Metals’ sales and marketing manager, said that the need to print and perform on flexible/bendable substrates continues to grow, in order to provide opportunities for more novel applications and to achieve R2R processing for high scalability and low-cost manufacturing of printed electronic products.

“Conductive inks now more than ever are required to be more robust, allowing for bending and stretching of the substrate with minimal effects on conductivity,” Babe continued. “While many device manufacturers have their own performance requirements in selecting conductive inks, standard performance testing procedures, and to some extent standard performance requirements, allow conductive ink manufacturers to test their inks in real-world environments to ensure industry requirements are met.”

Babe added that the use of flexible substrates and R2R printing has demanded a significant change in curing procedures.

“When thermally curing, low temperatures, around 150°C and below, are required,” Babe observed. “Alternative curing methods have been introduced to reduce cure time and alleviate the need for high-temperature thermal curing.”

“Customers are now much more educated as far as what their ink requirements are,” said Stan Farnsworth, chief marketing officer for NovaCentrix. “Early on in the space, electrical conductivity was the paramount requirement, whereas these days clients know they also need printability and adhesion. We’ve also seen growth in interest in inkjet printing, with clients purchasing systems with integrated print/cure capabilities.”

“It is clear that printed electronics manufacturers must be convinced that any innovation will enhance the device, be competitive, and have a reliable global supply infrastructure,” said Roy Bjorlin, global commercial and strategic initiatives director, Sun Chemical Advanced Materials. “This is especially true for smart packaging. For example, nanomaterials such as nanosilver could enable significant advancements in a broad range of applications, including photovoltaic and semiconductor packaging.”

IDTechEx CEO Raghu Das reported that IDTechEx has seen conductive ink formulations focused on specific applications, with suppliers creating many appropriate specialized formulations.

“Sectors such as photovoltaics (PV) and touch screens have seen strong demand for conductive ink with continual improvements in the ink to add value to the customer, such as better particle size control, uniformity etc.,” Das noted. “One of the main drivers has been moving to narrower printed tracks while retaining conductivity. PV demands this to improve efficiencies by exposure as much of the silicon wafer to the sunlight as possible. Here there has been continual improvement in ink and manufacturing to enable this.

“Over the past two years, we have seen many more applications receive interest from conductive ink makers, such as e-textiles and in-mold electronic, which have driven new conductive ink formulations including stretchable conductive ink,” Das added.

“Demands on raw materials like conductive inks have increased tremendously,” said Kerry Adams, European business development manager, DuPont Advanced Materials. “The inks have to perform across a broad range of application conditions and whereas it used to be just about conductivity and fine line performance, people now demand things such as stretchability, washability and formability. Compatibility across complex multilayers is necessary as people print more and more components of their particular device.”

“The performance targets of silver nanoparticles have been consistent – high conductivity and low-temperature sintering, coupled with ink and printing stability,” said Frank Wallace, technical director at NANOGAP, Inc. “The requirement for low-cost silver nanoparticles has increased in recent years. For silver nanowires, in touch panel applications, there is an increasing requirement for low haze performance and solutions to electro-migration issues. In applications outside of touch panels, the requirement is for good performance (not necessarily low haze) at low cost.”

“In the past, the requirements were focused strictly on flexible materials now was are seeing demand on elongation properties and surviving more dynamic conditions,” said Matthew Ganslaw, VP sales for Creative Materials. “An example of the new market demands includes washable and dry-able conductive inks.”

“Conductive ink requirements have evolved,” Alan Brown, applications manager, EMS, Inc., said. “Conductive inks must now be stretched, flexed and creased many times, in order to meet the specifications in these evolving markets.”

Steve Toyama, sales manager at Applied Ink Solutions, reported that customers have more applications for stretchable, elongating inks for disposable sensors. “We also have adapted to applying conductive inks in non-conventional applications like spraying and dipping,” Toyama added.

Bill Babe, Liquid-X Printed Metals’ sales and marketing manager, said that the need to print and perform on flexible/bendable substrates continues to grow, in order to provide opportunities for more novel applications and to achieve R2R processing for high scalability and low-cost manufacturing of printed electronic products.

“Conductive inks now more than ever are required to be more robust, allowing for bending and stretching of the substrate with minimal effects on conductivity,” Babe continued. “While many device manufacturers have their own performance requirements in selecting conductive inks, standard performance testing procedures, and to some extent standard performance requirements, allow conductive ink manufacturers to test their inks in real-world environments to ensure industry requirements are met.”

Babe added that the use of flexible substrates and R2R printing has demanded a significant change in curing procedures.

“When thermally curing, low temperatures, around 150°C and below, are required,” Babe observed. “Alternative curing methods have been introduced to reduce cure time and alleviate the need for high-temperature thermal curing.”