In 1953, Dr. Jean Bausch GmbH & Co. KG was founded, with an eye on specializing in the development and manufacturing of special articulating–occlusion materials. These test materials allow dentists to determine if the occlusion is correct in order to avoid TMJ pain to patients.

The tests have typically been done using paper or foils. In the case of Dr. Jean Bausch GmbH, its key products are articulating papers.

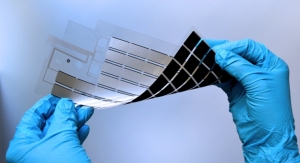

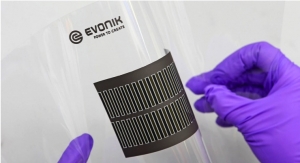

In 2019, the company launched its OccluSense system at the ADA FDI Dental Congress in San Francisco, earning awards for its new product. Complete with a handheld reader and an iPad app, OccluSense utilizes more than 1,000 printed sensors to accurately record the masticatory pressure. The sensor is thin and flexible.

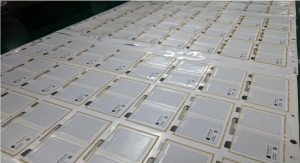

The beginnings of the OccluSense can be found in the collaboration between Dr. Jean Bausch GmbH and InnovationLab GmbH, a German research institute focused on printed and organic electronics. Heidelberg, a partner and shareholder of InnovationLab, has invested in a production facility that mass produces the OccluSense sensors. With OccluSense in the market, Dr. Jean Bausch GmbH is receiving excellent feedback and is looking at new possibilities for its technology.

Marcus Römermann, head of printed electronics for Heidelberger Druckmaschinen AG, talked about the OccluSense system.

“Occlusion tests have been made by using a color-coated paper which the patient bites on,” Römermann explained. “A couple of years ago, Andre Bausch, executive director of Dr. Jean Bausch, had the idea of trying to make improvements to the testing procedure. He knew there was R&D being conducted on these kinds of sensors and that was the initial start, so he contacted InnovationLab and developed the product together with them.”

OccluSense allows the dentist to capture the pressure digitally.

“When you bite on the sensor, the OccluSense records every situation between the first tooth contact and the final closure of the teeth, visualized by a graph on the screen, showing the results of the pressure distribution of the patient’s jaw. The sensor has more than 1,000 points which capture 256 levels of pressure. As this procedure is very precise, it helps the dentist to analyze the current occlusal status in a way they could not do before. If the patient, for example, suffers from headaches caused by bruxism, the dentist is able to adjust a splint with the OccluSense and the results can be recorded and compared during the treatment period,” Römermann said.

“We have a partnership with InnovationLab,” Römermann added. “The idea is they do the R&D and we do industrial production. Two years ago, they made their technological breakthrough, and that was the start for us. It allowed us to step into the business.”

InnovationLab uses the same Gallus RCS platform as Heidelberg, so whatever the research institute developed on its machine, Heidelberg could adapt it to industrialization. Still, there were challenges.

“The biggest challenge the InnovationLab mastered was to adapt the printing process to a mass suitable roll-to-roll process because it was never reached before like this,” Römermann noted. “InnovationLab can do pilot production. For smaller lot sizes, it is well known and established, but mass production is something new. We can do mass production on this, and therefore manufacturing costs are going down.

“We are reaching breakthrough price levels – we can think of completely new applications that were not possible before,” he added. “Volume and price weren’t there before We are working on new products for certain customers, such as smart bed sensor mats for hospitals.”

Römermann noted that Dr. Jean Bausch GmbH is receiving excellent feedback from dentists.

“Bausch has been selling its OccluSense system for the last couple of months, and has sold thousands of units,” he said. “It is getting really good feedback.

“We have a completely new process technology, and as far as I know, we are the first to be able to do an industrialized mass production like this,” Römermann concluded. “Now we are looking for other orders. We see a very good opportunity and are quite happy we did that investment and started this new business.”