With growing interest in renewable energy, there is increasing use of wind energy.

Once the wind turbines are up and running, maintaining the blades are a key expense and challenge, especially as some wind turbines are located as far as 25 miles out in the ocean.

It is an opportunity for flexible electronics.

The use of sensor systems to help lower the costs of production and operation is an area of interest for NextFlex, America’s Flexible Hybrid Electronics (FHE) Manufacturing Institute.

GE Research is partnering with researchers from Binghamton University, Georgia Tech, and Sikorsky on sensors that will monitor the turbines’ parts from manufacturing to its field operations.

Sikorsky is also exploring the use of these sensors in structural health monitoring of aircraft components.

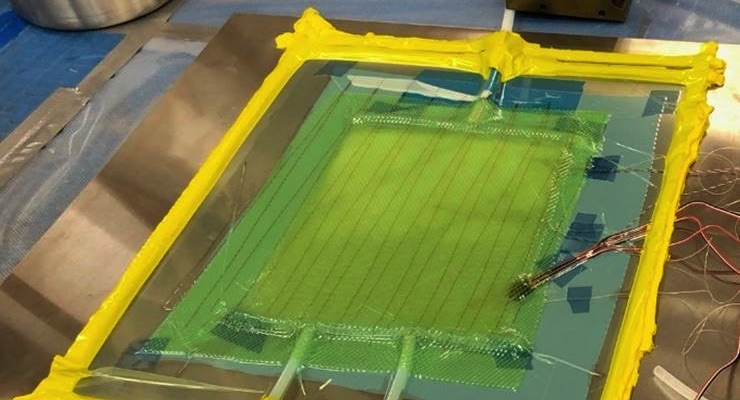

GE will embed the sensors during the manufacturing process to discover new ways to optimize the resin infusion and curing process, and utilizing a wireless approach to monitor the condition of these materials in factories, which could then be utilized to monitor structural health in the field.

Dr. Shridhar Nath, wind technology leader at GE Global Research, noted that the need for better ways to reduce the capital expenses of building a turbine and to monitor assets located as many as 25 miles offshore is becoming more important, and embedded sensors can be key.

“In the factory, embedded sensors will give us more valuable data points we otherwise would not have to make needed process improvements that take out cost and improve the quality of parts,” Nath said. “Once in the field, these sensors will provide a continuous line of sight to the condition of composite wind blades that will enable our business to move to a condition-based maintenance schedule that is more efficient and less costly.”

Dr. Nancy Stoffel, a principal engineer in GE Research’s Electronics & Sensing Group, said that the idea came through discussions at NextFlex on the applications for developing technologies, and through discussions with team members in GE Renewable Energy’s business about industry needs to enhance manufacturing and operations.

Stoffel added that there are two key benefits of the embedded sensors, which will be passive and thus not require batteries.

“The benefits are two-fold,” Stoffel added. “First, these sensors will provide feedback during the manufacturing process to ensure optimal quality and to enhance throughput. And second, it will enable us to provide real-time strain measurements in the field for machines such as offshore turbines that are located several kilometers out at sea. The sensors are passive and so do not require batteries or wiring for operation, and they can be our eyes and ears so to speak for monitoring the blades.”

Stoffel observed that each of the collaborators brings their expertise to the partnership.

“GE and Sikorsky both bring system-level knowledge of the application in manufacturing and structural health monitoring,” she added. “GE is providing expertise in composite fabrication, design and application in manufacturing. The GE composites group is creating composite test vehicles for both coupon and larger-scale item testing. The GE sensing team is guiding the team using our significant experience with sensor integration into real-life applications.

“The Binghamton University team is from the Center for Advanced Microelectronics Manufacturing led by Dr. Mark Poliks,” Stoffel continued. “They have deep experience with conformal printing, testing, and reliability. They are working on mechanical testing to test the effect of the sensors on the mechanical integrity of the structural composite. They will validate the strain sensor performance.

“The Georgia Tech group known as ATHENA (Agile Technologies for High-Performance Electromagnetic Novel Applications), led by Professor Manos Tentzeris focuses on advancing the development of electromagnetic technologies for high-performance novel sensing applications. They are leading the team in sensor design and interrogation for single and multiple patches,” Stoffel added.

Stoffel noted that NextFlex is ideal for this sort of partnership.

“NextFlex is a great catalyst for promoting a strong innovation ecosystem,” Stoffel said. “It brings together experts in systems applications, RF sensing and fabrication from different organizations and allows us to collaborate on basic technology and share learnings with the community. This, in turn, allows progress to go faster and be shared for a potential application not only in wind blades but in aircraft and many other composite applications.”

She added that GE’s business partners helped shape the focus of the project and are interested in doing field testing as the project progresses.

“The sensor concept could be adapted for many different structural health monitoring applications in composites. There are many potential application areas,” Stoffel concluded.