The COVID-19 pandemic has highlighted the need for necessary improvements in the medical system. Developing rapid testing capabilities in one obvious area. Another need is improving sample testing.

It is estimated that the UK’s National Health Services (NHS) could save as much as £250 million annually if it could make sample testing and pathology more efficient.

With that in mind, the NHS began a pilot project in the North East of England with Quality Hospital Solutions (QHS) and PragmatIC to improve pathology services and sample testing. The result is SamplePod, a novel reusable sample transportation and tracking system.

Andrew Turner, managing director of Quality Hospital Solutions (QHS) and inventor of SamplePod, said that SamplePod resulted from a request from an NHS pathology lab in the North East of England to QHS.

“The NHS hospital and lab needed a way to automatically track thousands of samples efficiently and accurately,” Turner said. “Managing the large volume of patient samples is a challenge for NHS labs as well as other private UK labs and similar facilities around the world. Thousands of samples stream through daily, and if one gets lost or damaged, a patient would have to come in to have a sample taken again. This is a significant cost to the NHS, as well as inconvenience for the patient, and their outcome may be affected.”

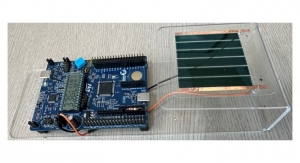

SamplePod is a novel sample transport and tracking solution that consists of a reusable pod in which up to 52 samples can be carried. It is designed to accommodate a wide variety of different sizes of test tubes. PragmatIC designed and produced low-cost RFID labels encoded with unique digital IDs. As a result, each sample within the pod can be fully tracked in real-time from the patient all the way through to the pathology lab.

“PragmatIC’s cutting-edge flexible integrated circuit technology allows ultra-low-cost RFID to be added to every sample tube, giving each one a unique digital identity that can be read wirelessly, in real-time from the patient all the way through to the pathology lab,” Alastair Hanlon, PragmatIC’s chief commercial officer, said. “As each individual sample has a unique ID, no sensitive patient information is stored anywhere in the SamplePod.

“At the point when the sample is taken, each sample tube is associated with a master RFID tag within the SamplePod itself,” he added. “The clinician generating the samples can then send a notification to the lab of the expected arrival time of the SamplePod and what is required for the associated samples. At the lab, the SamplePod is quickly scanned with a reader and the samples verified, identifying any time-critical ones, these samples can very swiftly be moved on to testing.”

There were challenges that had to be overcome for SamplePod to be effective, beginning with the need for the chips to be flexible. PragmatIC’s ultra-low-cost and thin flexible integrated circuits (FlexICs) provided the solution.

“Conventional RFID inlays use silicon chips, or integrated circuits (ICs), but the rigid form factor and relatively high cost of these tags make them unsuitable for high volume healthcare applications like SamplePod,” Hanlon observed. “Tags based on PragmatIC’s RFID FlexICs can be easily applied to the small circumference test tubes and bottles to provide the unique identification required.”

Turner pointed out that in recent years, there have been considerable changes in pathology services, including the consolidation in several regions of multiple in-house hospital facilities into large mega labs that are designed to be centers of excellence. SamplePod can play a significant role in improving testing.

“While this has provided some benefits, there are still inefficiencies that prevent the labs operating at full capacity, and the COVID-19 pandemic has placed the sector under extreme pressure,” Turner added. “Traditionally, the incoming samples are manually unpacked and sorted at the labs, plus come with a lot of paperwork to be processed. It is very time-consuming, requires significant numbers of staff and is prone to errors. Samples can be lost or damaged in transit, paperwork can be misplaced or mismatched. All of which must be recorded and reported and tests reordered.

“The SamplePod system reduces the time that was previously spent unpacking lots of plastic bags, plus there are costs savings from the reduction of the use of the bags and the costs associated with disposing of packaging that is deemed as clinical waste,” Turner continued. “Also, the fact that labs will have prior warning of which samples are on their way saves valuable time and resources, as staff can define the optimum schedule of work and maximize the use of the lab equipment.”

Turner said that the initial NHS trials in the North East have progressed well and SamplePod is generating considerable interest from healthcare organizations across the globe.

“Assuming the next steps go well in the region, the vision is to roll this system out across the whole of the UK pathology network, with a projection that it could save the NHS an estimated £250 million a year,” Turner concluded. “It is envisaged that in the future, additional functionality could be added to the process, such as robotics designed to unpack and sort the samples. The SamplePod system could also be used with temperature monitoring tags to ensure the samples are kept in a consistent environment.”

SamplePod. (Source: PragmatIC)