David Savastano, Editor11.07.14

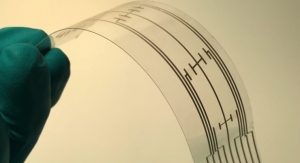

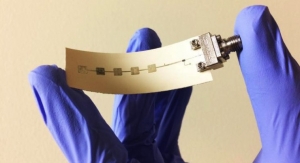

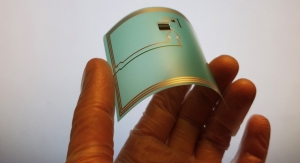

The decision between types of substrates, whether it is paper, plastic film, metal or other, is critical in the design of printed electronics systems. Each of these substrates has its advantages and disadvantages. Whether one selects polyethylene terephthalate (PET), polyethylene-naphthalate (PEN), polyimide (PI), paper, foil or some other substrate, the performance characteristics of the substrate will impact the application.

Stefano Favero, division manager, Coveme Spa, noted that Coveme is a PET converter and buys polyester from major suppliers around the world. Coveme adds value to PET with specific treatments: functional coatings, temperature treatments or lamination.

“The PE industry is focusing on using PET, which is more resistant to tearing and humidity compared to paper, for instance, and cheaper than hi-temp solutions such as PI,” Favero noted. “PET has nice features, but these have to be controlled; I think about its natural shrinkage or the rolls’ skew. This is the know-how we have developed in almost 50 years.

“For the printed electronics market, we cover the polyester films specifically for flexible circuitry, RFID tags and NFC devices,” Favero added. “We apply ‘tca,’ a specific surface treatment that uses nanodimensional silica flakes; when it dries, you have basically changed the native PET surface tension, allowing targets of 58 dynes and up.

“This allows premium adhesion with conductive inks and pastes, but also with conventional inks and water-based or hot melt adhesives. Other print primers are also available, to complete the product range,” Favero added.

The latter coatings technologies are alternatives to surface treatment and are ideal for transparent applications.

“Surface treatments would turn a clear film hazy, and some customers require crystal clear substrates,” Favero reported. “When necessary, PET undergoes a heat stability process; in essence, we let the film go through a dedicated oven, whose temperatures can be tuned through its length and width in different oven areas, reducing pulling tensions and allowing a controlled film shrinkage. Past 78°C (glass transition temperature), polyester starts to shrink; what Coveme does is master this dynamic and let the film relax.”

Arjowiggins Creative Papers’ PowerCoat is a relatively new technology for printed electronics. Launched in 2012, PowerCoat is a sustainable substrate with exceptional smoothness (the company reports as low as 10 microns). It is naturally roll-to-roll, and its smoothness allows for fine patterning as low as five microns. This makes it ideal for sensors, RFID tags, printed batteries and more.

“This paper has been in the making for years,” said Jose-Anne d’Auvergne, brand manager at Arjowiggins Creative Papers. “We not only saw a gap in the market, but we also believe that there is major potential for this recyclable, biodegradable paper substrate in the PE market.”

Brian Marks, general manager, Functional Printing, Eastman Kodak Company, said that Kodak’s differentiated technology and expertise includes extensive deposition experience, materials design, synthesis and formulations, roll-to-roll conveyance and image science plus a range of manufacturing and service capabilities.

“These strengths are being used to support an innovative portfolio of solutions via low-cost, continuous manufacturing processes,” Marks said. “Included in the mix are touch screen sensors, printed circuit boards, smart packaging and brand protection solutions. Kodak is pursuing a partnership approach in several areas of our traditional businesses, and functional printing is no exception.”

Key Markets

The markets for these substrates are varied. PET has a long history in printed circuit boards and membrane switches, and has become a popular choice for flexible and printed electronics. For example, Scott E. Gordon, business development manager, DuPont Teijin Films, noted that in general, DuPont Teijin Films’ products are used as substrates for transparent conductor films for touch sensors, display backplanes, automotive seat heaters, medical test strips, membrane switches for MMIs (e.g. appliances, controls), lighting and other applications.

Coveme’s films are used in a wide variety of PE markets.

“We supply films for sensors, NFC and RFID, flexible printed circuit boards, blood glucose test strips (including hydrophilic top layers), ECG and EKG patches, LED lighting, automotive applications and flat cables,” Favero said.

Marks said that functional printing is applicable to a variety of vertical markets, including displays, printed electronics and smart packaging.

“The application space includes touch sensor panels, brand protection solutions such as anti-diversion and anti-counterfeiting technologies, RFID tags and chemical sensors, such as temperature, shock or tamper sensors, and actuators for intelligence in textiles and smart packaging,” Marks said. “These applications continue to grow each and every day, and are demanding more variety in the formats and sizes as well as requiring design flexibility and variability in how new technologies are addressing these applications.

“Kodak’s initial entry point into this market is in touch screen sensors,” Marks added. “Kodak is working with several customers, assisting them with setting up their own manufacturing and production lines so they can produce high quality sensors. These sensor solutions are for use in projective capacitive consumer electronic applications ranging from mobile phones and tablets to laptop and AiO applications, as well as in a number of industrial applications, such as automotive dashboards, home appliances and interfaces for manufacturing equipment.

“Here is one example concerning our PET films: MacDermid Autotype Ltd. purchases a wide range of Kodak PET base films to which a value-added hard coating and ink primer are applied,” Marks added. “These hard coated PET films are supplied to a global group of industrial customers, who manufacture final products such as membrane touch switches, touch screens, graphic overlays and nameplates with final products used in the electronics, automotive and appliance market sectors.”

PowerCoat HD was Arjowiggins’ initial product line for printed electronics, utilized for inkjet, screen, flexo, gravure and offset printing and vacuum deposition systems. PowerCoat XD, Arjowiggins’ newest offering, is designed for screen, flexo, gravure and offset printing. PowerCoat is thermally stable and is capable of supporting several manufacturing processes, including air drying, infrared or photonic flash sintering technologies up to 200°C to 220°C.

Advantages of Substrates

Each of these substrate choices offers specific advantages to the end user. Gordon noted that plastic substrates such as PET offer some key advantages, including durability, chemical and moisture resistance, and heat stability.

Marks said that functional printing uses deposition and/or printing technologies to print onto substrates with the intent to create a subcomponent, component or finished product, which in turn enables functionality beyond visual communications.

“The continuous manufacturing processes enable higher efficiency and productivity compared to traditional batch processing techniques, Marks reported. “Lower costs are achieved through automated processes, which net economies of scale and involve less labor and less capital.

“In short, functional printing has enabled complex structures to be manufactured more economically,” Marks added. “The technology offers the unique advantages for metal mesh touch sensors based on roll-to-roll, flexible processes, as compared to the traditional ITO-based touch sensor solutions.

“In addition the manufacturing process is more efficient and sustainable with lower production costs versus standard ITO-based touch technology, lower material costs, fewer steps in the manufacturing process and a more simplified supply chain,” Marks added.

“With respect to our PEDOT/PSS line, the portfolio of Kodak Highly Conductive (HCF) films features a very stable coating, with excellent optical quality, as well as cost/performance advantages over existing transparent conductive films,” Marks noted. “In terms of their physical performance, Kodak HCF films are very easy to work with due to the flexibility of the coating for both resistive and capacitive technology applications. With Kodak HCF Film, customers can produce flexible sensors with an invisible pattern on one or both sides of the film. By using both sides of the film, customers can produce thinner sensors that are beneficially more cost-advantageous compared to other technologies.”

The customer’s requirements drive the selection of the substrates. Favero noted that stability is essential for print accuracy.

“Customers need a film that is stable for print accuracy on multi-step processes,” Favero said. “This dimensional treatment is done roll-to-roll. The key challenge is to keep the print register at each print passage. Inks, pastes and coatings must then stick to the substrate, and our products meet these needs.

“Hence, dimensional stability is key,” Favero added. “Yield is strictly related to roll-to-roll processes. Everybody can stabilize sheets in ovens, but roll-to-roll is a challenge. We are known to be reliable.”

D’Auvergne said that PowerCoat benefits from all the characteristics of being a paper.

“PowerCoat can be easily bended, folded, torn, burnt, etc., which are all unique characteristics versus other substrates currently on the market,” said d’Auvergne. “This can then trigger other desired results (for example, a message sent when the paper is torn/circuit is broken etc.) These characteristics make this substrate particularly interesting for packaging or labeling applications, for example.”

Challenges for Substrate Manufacturers

There are important challenges that substrate manufacturers are asked to help solve, including optical quality and clean surfaces.

“Kodak’s long history of image science, deposition expertise and substrate knowledge creates a unique opportunity to apply these competencies to new unique sets of technical requirements,” Marks said. “Optical quality and thermal stability are highest among these requirements, as well as the need to address various surface properties of substrates to promote adhesion and other integration requirements. These are frequently accomplished through our proprietary manufacturing approaches and strong materials science expertise. From the standpoint of go-to-market, flexible film solutions offered by Kodak represent a disruptive technology within segments of the conductive film industry.”

“Requests for clear, clean, defect-free substrates for displays and other applications are driving our innovation efforts, and have resulted in films such as Clean-on-Demand,” said Gordon. “Rather than awaiting the invention and scale-up of exotic new substrates, many customers are trying to drive their processing temperatures down so they can utilize existing, commercial substrates such as PET and PEN. This requires close collaborations among OEMs and their suppliers in order to maximize the substrate’s performance.”

Outlook for Flexible and Printed Electronics

Flexible and printed electronics is a growth market, and substrate manufacturers see more opportunities ahead. Gordon anticipates continued growth in current and new applications.

“We are still relatively new to the industry, but we would not have entered this industry if we did not believe that it had tremendous growth potential,” d’Auvergne said. “In addition to our traditional uses of paper, we think that this innovation has been a great addition to our product portfolio, as it not only reflects our innovative capabilities, but also that paper is alive and that alternative uses can always be found for traditional products.”

Kodak’s spokesperson said that the market is fast being transformed.

“New applications and market trends are changing the requirement landscape, and in many instances stretching it beyond what incumbent solutions can readily achieve,” Marks said. “The key drivers are market tendencies toward higher performance, lower cost and thinner, more robust flexible designs.

“The touch screen sensor market represents a high-potential opportunity for Kodak,” Marks added. “The market is demanding design variations and flexibility, which are driving new technologies. Larger formats and new applications are creating requirements for better conductivity and durability the manufacturers are requiring lower cost components and decreased manufacturing times in order to meet demands.

“The market is very large – for touch sensor modules specifically, the market is projected to grow at double-digit rates from $16 billion in 2012 to $28 billion in 2015. And with unit growth rates predicted to address the various applications also in the double digits, we believe this is a key market to enter into with our functional printing solutions and represents a sustainable opportunity for the new Kodak,” Marks concluded.

Favero sees opportunities for flexible printed electronics.

“Our outlook is extremely positive,” Favero concluded. “We are seeing a lot of energy in flexible substrates, with dimensional properties and superior printability driving the desire for bendable and curved solutions. I am also seeing growing demand for our RFID and NFC products.”

Stefano Favero, division manager, Coveme Spa, noted that Coveme is a PET converter and buys polyester from major suppliers around the world. Coveme adds value to PET with specific treatments: functional coatings, temperature treatments or lamination.

“The PE industry is focusing on using PET, which is more resistant to tearing and humidity compared to paper, for instance, and cheaper than hi-temp solutions such as PI,” Favero noted. “PET has nice features, but these have to be controlled; I think about its natural shrinkage or the rolls’ skew. This is the know-how we have developed in almost 50 years.

“For the printed electronics market, we cover the polyester films specifically for flexible circuitry, RFID tags and NFC devices,” Favero added. “We apply ‘tca,’ a specific surface treatment that uses nanodimensional silica flakes; when it dries, you have basically changed the native PET surface tension, allowing targets of 58 dynes and up.

“This allows premium adhesion with conductive inks and pastes, but also with conventional inks and water-based or hot melt adhesives. Other print primers are also available, to complete the product range,” Favero added.

The latter coatings technologies are alternatives to surface treatment and are ideal for transparent applications.

“Surface treatments would turn a clear film hazy, and some customers require crystal clear substrates,” Favero reported. “When necessary, PET undergoes a heat stability process; in essence, we let the film go through a dedicated oven, whose temperatures can be tuned through its length and width in different oven areas, reducing pulling tensions and allowing a controlled film shrinkage. Past 78°C (glass transition temperature), polyester starts to shrink; what Coveme does is master this dynamic and let the film relax.”

Arjowiggins Creative Papers’ PowerCoat is a relatively new technology for printed electronics. Launched in 2012, PowerCoat is a sustainable substrate with exceptional smoothness (the company reports as low as 10 microns). It is naturally roll-to-roll, and its smoothness allows for fine patterning as low as five microns. This makes it ideal for sensors, RFID tags, printed batteries and more.

“This paper has been in the making for years,” said Jose-Anne d’Auvergne, brand manager at Arjowiggins Creative Papers. “We not only saw a gap in the market, but we also believe that there is major potential for this recyclable, biodegradable paper substrate in the PE market.”

Brian Marks, general manager, Functional Printing, Eastman Kodak Company, said that Kodak’s differentiated technology and expertise includes extensive deposition experience, materials design, synthesis and formulations, roll-to-roll conveyance and image science plus a range of manufacturing and service capabilities.

“These strengths are being used to support an innovative portfolio of solutions via low-cost, continuous manufacturing processes,” Marks said. “Included in the mix are touch screen sensors, printed circuit boards, smart packaging and brand protection solutions. Kodak is pursuing a partnership approach in several areas of our traditional businesses, and functional printing is no exception.”

Key Markets

The markets for these substrates are varied. PET has a long history in printed circuit boards and membrane switches, and has become a popular choice for flexible and printed electronics. For example, Scott E. Gordon, business development manager, DuPont Teijin Films, noted that in general, DuPont Teijin Films’ products are used as substrates for transparent conductor films for touch sensors, display backplanes, automotive seat heaters, medical test strips, membrane switches for MMIs (e.g. appliances, controls), lighting and other applications.

Coveme’s films are used in a wide variety of PE markets.

“We supply films for sensors, NFC and RFID, flexible printed circuit boards, blood glucose test strips (including hydrophilic top layers), ECG and EKG patches, LED lighting, automotive applications and flat cables,” Favero said.

Marks said that functional printing is applicable to a variety of vertical markets, including displays, printed electronics and smart packaging.

“The application space includes touch sensor panels, brand protection solutions such as anti-diversion and anti-counterfeiting technologies, RFID tags and chemical sensors, such as temperature, shock or tamper sensors, and actuators for intelligence in textiles and smart packaging,” Marks said. “These applications continue to grow each and every day, and are demanding more variety in the formats and sizes as well as requiring design flexibility and variability in how new technologies are addressing these applications.

“Kodak’s initial entry point into this market is in touch screen sensors,” Marks added. “Kodak is working with several customers, assisting them with setting up their own manufacturing and production lines so they can produce high quality sensors. These sensor solutions are for use in projective capacitive consumer electronic applications ranging from mobile phones and tablets to laptop and AiO applications, as well as in a number of industrial applications, such as automotive dashboards, home appliances and interfaces for manufacturing equipment.

“Here is one example concerning our PET films: MacDermid Autotype Ltd. purchases a wide range of Kodak PET base films to which a value-added hard coating and ink primer are applied,” Marks added. “These hard coated PET films are supplied to a global group of industrial customers, who manufacture final products such as membrane touch switches, touch screens, graphic overlays and nameplates with final products used in the electronics, automotive and appliance market sectors.”

PowerCoat HD was Arjowiggins’ initial product line for printed electronics, utilized for inkjet, screen, flexo, gravure and offset printing and vacuum deposition systems. PowerCoat XD, Arjowiggins’ newest offering, is designed for screen, flexo, gravure and offset printing. PowerCoat is thermally stable and is capable of supporting several manufacturing processes, including air drying, infrared or photonic flash sintering technologies up to 200°C to 220°C.

Advantages of Substrates

Each of these substrate choices offers specific advantages to the end user. Gordon noted that plastic substrates such as PET offer some key advantages, including durability, chemical and moisture resistance, and heat stability.

Marks said that functional printing uses deposition and/or printing technologies to print onto substrates with the intent to create a subcomponent, component or finished product, which in turn enables functionality beyond visual communications.

“The continuous manufacturing processes enable higher efficiency and productivity compared to traditional batch processing techniques, Marks reported. “Lower costs are achieved through automated processes, which net economies of scale and involve less labor and less capital.

“In short, functional printing has enabled complex structures to be manufactured more economically,” Marks added. “The technology offers the unique advantages for metal mesh touch sensors based on roll-to-roll, flexible processes, as compared to the traditional ITO-based touch sensor solutions.

“In addition the manufacturing process is more efficient and sustainable with lower production costs versus standard ITO-based touch technology, lower material costs, fewer steps in the manufacturing process and a more simplified supply chain,” Marks added.

“With respect to our PEDOT/PSS line, the portfolio of Kodak Highly Conductive (HCF) films features a very stable coating, with excellent optical quality, as well as cost/performance advantages over existing transparent conductive films,” Marks noted. “In terms of their physical performance, Kodak HCF films are very easy to work with due to the flexibility of the coating for both resistive and capacitive technology applications. With Kodak HCF Film, customers can produce flexible sensors with an invisible pattern on one or both sides of the film. By using both sides of the film, customers can produce thinner sensors that are beneficially more cost-advantageous compared to other technologies.”

The customer’s requirements drive the selection of the substrates. Favero noted that stability is essential for print accuracy.

“Customers need a film that is stable for print accuracy on multi-step processes,” Favero said. “This dimensional treatment is done roll-to-roll. The key challenge is to keep the print register at each print passage. Inks, pastes and coatings must then stick to the substrate, and our products meet these needs.

“Hence, dimensional stability is key,” Favero added. “Yield is strictly related to roll-to-roll processes. Everybody can stabilize sheets in ovens, but roll-to-roll is a challenge. We are known to be reliable.”

D’Auvergne said that PowerCoat benefits from all the characteristics of being a paper.

“PowerCoat can be easily bended, folded, torn, burnt, etc., which are all unique characteristics versus other substrates currently on the market,” said d’Auvergne. “This can then trigger other desired results (for example, a message sent when the paper is torn/circuit is broken etc.) These characteristics make this substrate particularly interesting for packaging or labeling applications, for example.”

Challenges for Substrate Manufacturers

There are important challenges that substrate manufacturers are asked to help solve, including optical quality and clean surfaces.

“Kodak’s long history of image science, deposition expertise and substrate knowledge creates a unique opportunity to apply these competencies to new unique sets of technical requirements,” Marks said. “Optical quality and thermal stability are highest among these requirements, as well as the need to address various surface properties of substrates to promote adhesion and other integration requirements. These are frequently accomplished through our proprietary manufacturing approaches and strong materials science expertise. From the standpoint of go-to-market, flexible film solutions offered by Kodak represent a disruptive technology within segments of the conductive film industry.”

“Requests for clear, clean, defect-free substrates for displays and other applications are driving our innovation efforts, and have resulted in films such as Clean-on-Demand,” said Gordon. “Rather than awaiting the invention and scale-up of exotic new substrates, many customers are trying to drive their processing temperatures down so they can utilize existing, commercial substrates such as PET and PEN. This requires close collaborations among OEMs and their suppliers in order to maximize the substrate’s performance.”

Outlook for Flexible and Printed Electronics

Flexible and printed electronics is a growth market, and substrate manufacturers see more opportunities ahead. Gordon anticipates continued growth in current and new applications.

“We are still relatively new to the industry, but we would not have entered this industry if we did not believe that it had tremendous growth potential,” d’Auvergne said. “In addition to our traditional uses of paper, we think that this innovation has been a great addition to our product portfolio, as it not only reflects our innovative capabilities, but also that paper is alive and that alternative uses can always be found for traditional products.”

Kodak’s spokesperson said that the market is fast being transformed.

“New applications and market trends are changing the requirement landscape, and in many instances stretching it beyond what incumbent solutions can readily achieve,” Marks said. “The key drivers are market tendencies toward higher performance, lower cost and thinner, more robust flexible designs.

“The touch screen sensor market represents a high-potential opportunity for Kodak,” Marks added. “The market is demanding design variations and flexibility, which are driving new technologies. Larger formats and new applications are creating requirements for better conductivity and durability the manufacturers are requiring lower cost components and decreased manufacturing times in order to meet demands.

“The market is very large – for touch sensor modules specifically, the market is projected to grow at double-digit rates from $16 billion in 2012 to $28 billion in 2015. And with unit growth rates predicted to address the various applications also in the double digits, we believe this is a key market to enter into with our functional printing solutions and represents a sustainable opportunity for the new Kodak,” Marks concluded.

Favero sees opportunities for flexible printed electronics.

“Our outlook is extremely positive,” Favero concluded. “We are seeing a lot of energy in flexible substrates, with dimensional properties and superior printability driving the desire for bendable and curved solutions. I am also seeing growing demand for our RFID and NFC products.”