David Savastano, Editor11.07.14

When the idea of flexible and printed electronics first came to prominence, solar was one of the key potential markets. Screenprinting is already used in traditional solar operations to print the backplane, among other areas. The vision was to be able to print solar materials onto flexible substrates, thus reducing costs and increasing production.

With this dream in place, a wide range of entrepreneurs headed to the marketplace, with venture capital groups providing lots of funding. Companies such as Konarka Technologies and Solyndra received millions of dollars in funding, from venture capital firms and/or the government, and built production-scale operations to manufacture their products. Researchers worked on thin-film technologies ranging from organic photovoltaics (OPV) to copper indium gallium selenide (CIGS), among others.

As we know now, these companies, and many others with them, never succeeded commercially. Many went out of business, including Konarka and Solyndra; others were sold or scaled back considerably.

What happened? Well, there are different reasons for each company, but it boiled down to this: the companies could not take the results they achieved in the lab and bring them to production. Without the efficiencies and lifetimes the market demanded, there was no way for these companies to succeed.

However, there are companies working in the OPV market who are finding opportunities, and researchers are making advances that one day may bring success to the OPV field.

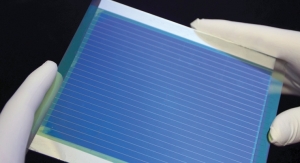

Heliatek GmbH has arguably had the most success in the market. Heliatek develops and synthesizes small organic molecules - oligomers – and uses the deposition of these molecules in a low temperature, roll-to-roll vacuum process.

Last year, Heliatek signed a development agreement with AGC Glass Europe, the European branch of AGC (the world’s largest producer of flat glass), to develop building integrated photovoltaics (BIPV) by integrating organic solar films in glass to collect solar energy.

With BIPV, the sides of buildings, including windows, can be used to collect solar energy. This offers much more square footage, and thus opportunity, than simply roof top collection. Heliatek’s ultra-thin, organic Solar Film can be opaque or semi-transparent in a variety of colors for design purposes.

Dr. Thomas Bickl, vice president sales and product development for Heliatek GmbH, noted that Heliatek has made steady efficiency improvements in recent years, both on the lab scale and on production-ready films.

“In 2013, we obtained a third party certified world record of 12% STC efficiency on lab scale cells (4.35 cm²), and just recently we reached 7% efficiency on a 2m long module produced on our pilot line in Dresden,” Dr. Bickl said.

Michael Niggemann, chief technology officer for Eight19 Ltd., noted that the improvements and progress in the field of OPV are very encouraging on multiple levels.

“Organic photovoltaic modules are built up from a number of components, which, when combined, can all contribute to increased efficiency, reduced cost and longer life time,” Niggemann said. “Encapsulation materials have improved while the projected cost has dropped. A significant effort has been and is being dedicated to improving the stability of the photoactive stack, including electrodes and injection layers, which has resulted in champion efficiencies exceeding 10%.

“Central to Eight19’s development activities is the development of a low cost module architecture and related high volume manufacturing processes,” Niggemann added. “We have successfully demonstrated large roll-to-roll fabricated modules, and we are now in the process of developing solutions for customers.”

Advantages of OPVs

OPVs offer numerous advantages, beginning with the ability to produce lightweight, flexible materials with roll-to-roll processes. OPVs also efficiently collect energy in areas with low lighting. For example, Dr. Bickl said that Heliatek offers some unique advantages, such as its superior energy harvesting factor.

“Under low light conditions and at temperatures between 40°C and 75°C, our film generates substantially more energy per installed power than silicon or other thin film materials,” Dr. Bickl said. “Recent long term data from an outdoor test site points to 25% more energy generated than standard silicon modules (kWh/kWp). This would make very suitable for hot climates and non-optimal installation conditions.

“More important, however, are factors like our low weight (0.5 kg/m² compared to 15 kg/m² silicon), our ability to produce transparent solar cells at good efficiencies (latest 7% at 40% transparency) and geometrical flexibility due to our PET substrate,” he added. “Above all, our customers acknowledge that OPV is a truly green energy, with very short energy pay back times (less than six months) and no toxic or rare earth materials embedded.”

“OPV solar modules are light weight, flexible and robust,” Niggemann said. “High-volume roll-to-roll production is particularly suited to solution deposition of organic semiconductor materials and is key for low cost production. In combination with distinct properties such as high performance over a wide range of light intensities, the ability to produce semi-transparent modules of various colors opens up opportunities for new applications which existing solar technologies cannot address or are less well suited to.”

The European Union has funded MUJULIMA to solve some of the challenges facing OPV, including developing new materials, inks, cell architecture, light management technologies and inkjet printing process, enabling the production of high efficiency and long lifetime OPV.

Coordinated by TNO/Holst Centre, MUJULIMA will run until Dec. 31, 2016. MUJULIMA has nine members, including DisaSolar, which manufactures customized OPV modules through the use of digital inkjet printing processes and product integration. DisaSolar also produces flexible CIGS and thin film Si-based solar modules.

“OPV has several specific selling points to differentiate from other PV technologies: light weight, freedom in shape, substrate and color, semi-transparency and processing speed,” said Jan Gilot of TNO, who is MUJULIMA’s project coordinator. “The current status of OPV is around 10-12% efficiency on lab scale, with a lifetime varying between one to five years depending on the encapsulation.”

“OPV shows great features that differentiate it from the existing technologies, such as flexibility, low weight and freedom in the design and color,” Laurence Dassas, chief technology officer of DisaSolar, noted. “However, its efficiency and lifetime are still low.

Improvement in OPV performance by MUJULIMA is crucial for the development of DisaSolar through new markets and larger market share. Synthesis of new materials and ink formulations, optimization of the cell architecture and development of the inkjet process are required to achieve the goal of the project.”

Gilot said that MUJULIMA’s objective is an efficiency of 15% and a lifetime of 10 years. He said that the final step will be to bring the advances to the production line.

“The final goal is to achieve our objectives in efficiency and lifetime not only in the lab, but also prove it in production environment with striking demonstrators for indoor charging equipment, urban furniture and transport (e.g. bus, train, car),” Gilot concluded.

The Centre for Process Innovation (CPI) is also conducting research into OPV production. Alf Smith, business development manager for CPI, said that lower production costs for OPVs are another advantage, as is the environmentally friendly nature of the ingredients.

“One differentiator is the potential for the implementation of low cost and resource efficient manufacturing techniques,” Smith said. “OPVs can be coated at low temperatures and at high speed, meaning that they will be cheaper and easier to be mass produced than other technologies. In addition, OPVs contain no toxic metals, meaning that they are environmentally friendly throughout their lifecycle.”

Key Markets for OPV

Considering the advantages that OPV offers, the niche markets it could impact are many. As an example, while OPV would not be ideal for solar farms or rooftop installations due to lower efficiencies, its low weight and flexibility make it ideal for other end uses.

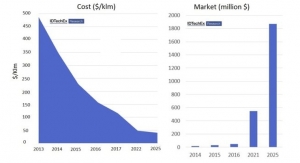

Edward Cahill, an analyst with Lux Research, sees smaller, niche markets as the best potential for thin-film PV suppliers. In a recent report, “Into the Niche: Putting a Magnifying Glass on PV’s Tiniest Markets,” Cahill placed these markets as a 1.2 gigawatt opportunity, led by BIPV.

“Market adoption has been limited and will remain small relative to conventional solar demand, but the niche application can be a profitable side business that supports a core business market,” Cahill said.

Lux Research believes that facades and roofing products such as solar shingles are a fast-growing segment for BIPV, followed by solar chargers.

BIPV is one area of great potential. Harvesting the sun’s rays in order to power buildings would be both sustainable and cost-efficient, once the equipment pays for itself. Of course, no one wants their windows to be full of wires or, worse yet, not be transparent.

New Energy Technologies, Inc. has created Solar Window, a patented technology that generates clean electricity on see-through glass windows, making use of the energy of natural sunlight and artificial sources such as fluorescent and LED lighting.

“Unlike conventional systems, SolarWindow can be applied to all four sides of tall towers, generating electricity using natural and artificial light conditions and even shaded areas,” said John Conklin, president and CEO of New Energy Technologies, Inc. “SolarWindow uses organic materials, which are dissolved into liquid, ideal for low-cost high-output manufacturing.”

These cells are sprayed on to see-through glass at room temperature using a novel, patent-pending process

Dr. Bickl noted that OPV can succeed in market segments where silicon is not suitable, such as BIPV, automotive and special applications, where low weight and other form factors are advantages.

“A German producer of overpressure halls will use our modules on top of his inflated structure to generate the power needed to drive the pressure compressor, thus reducing substantially the operating cost for his customers,” Dr. Bickl said. “No other PV technology could do this due to the unique combination of low weight and superior energy harvesting factor.”

Niggemann noted that new technologies most often find their way into large scale established markets through emerging markets.

“Sometimes these emerging markets can exceed the size of existing markets. Eight19 is focusing on a number of emerging markets rather than the traditional mainstream photovoltaic energy market,” Niggemann said.

“We see significant potential in a number of emerging markets,” Niggemann added. “The indoor energy harvesting market is growing as more technology is integrated in the built environment. Light is in most cases an effective source for energy indoors. Eight19’s OPV can play to its strengths with its outstanding low-light performance and easy lamination to surfaces to address this emerging market.”

The off-grid solar market is seen as an excellent opportunity, as solar chargers can replace kerosene or diesel as a means to provide electricity.

“We see off-grid solar as the next accessible, strongly growing market,” Niggemann noted. “Today some 1.3 billion people have no access to electricity, and this number is currently projected to barely change in the foreseeable future, with some 1.2 billion people globally still forecast to be without access to electricity in 2030.

“Traditional solar generation efforts have focused on replacing fossil fuel-based power generation for mainstream electrical applications (so-called ‘on-grid’ power),” he continued. “However, in countries where the distribution grid infrastructure itself is lacking, another market is rapidly growing for domestic and consumer applications that are not connected to electricity. Such devices are frequently powered by batteries, kerosene or diesel generators – all of which have a disproportionately high environmental impact as well as a high cost compared to standard on-grid electricity. In particular the robustness and the low weight of Eight19’s plastic solar provided at an affordable cost point is expected to make it highly attractive in off-grid applications ranging from phone charging to lighting and even communal installations.

“The building integrated market is also a promising long-term market,” Niggemann concluded. “In particular, the options of semi-transparency and choice in colors make OPV attractive for window and glass facade applications.”

“The development of organic photovoltaics with flexible form factors opens up a host of design opportunities and will lead to the creation of a range of electronic applications in key market sectors such as automotive, print and packaging, construction and healthcare,” Smith said. “The integration of conformable OPV increases the freedom for product designers to embed technology and functionality into their designs, creating the opportunity for new, innovative components that are wireless, smarter, interactive, conformable, thinner, lightweight, rugged and able to blend into our environment.

“In the future we have no doubt that flexible OPV will be produced in large areas and in high volumes, with extensive product lifetimes – properties ideal for innovative automotive/architectural applications,” Smith noted. “However, likewise with OLED, the short term value is to pursue niche applications where the technology is viable today.

“Organic photovoltaics will not only target existing markets, but will also lead to the creation of new markets and novel applications such as smart therapeutic bandages for managing and monitoring the recovery of wounds, wearable electronics for monitoring and improving athletic performance and highly efficient curved architectural solar power,” Smith added.

With this dream in place, a wide range of entrepreneurs headed to the marketplace, with venture capital groups providing lots of funding. Companies such as Konarka Technologies and Solyndra received millions of dollars in funding, from venture capital firms and/or the government, and built production-scale operations to manufacture their products. Researchers worked on thin-film technologies ranging from organic photovoltaics (OPV) to copper indium gallium selenide (CIGS), among others.

As we know now, these companies, and many others with them, never succeeded commercially. Many went out of business, including Konarka and Solyndra; others were sold or scaled back considerably.

What happened? Well, there are different reasons for each company, but it boiled down to this: the companies could not take the results they achieved in the lab and bring them to production. Without the efficiencies and lifetimes the market demanded, there was no way for these companies to succeed.

However, there are companies working in the OPV market who are finding opportunities, and researchers are making advances that one day may bring success to the OPV field.

Heliatek GmbH has arguably had the most success in the market. Heliatek develops and synthesizes small organic molecules - oligomers – and uses the deposition of these molecules in a low temperature, roll-to-roll vacuum process.

Last year, Heliatek signed a development agreement with AGC Glass Europe, the European branch of AGC (the world’s largest producer of flat glass), to develop building integrated photovoltaics (BIPV) by integrating organic solar films in glass to collect solar energy.

With BIPV, the sides of buildings, including windows, can be used to collect solar energy. This offers much more square footage, and thus opportunity, than simply roof top collection. Heliatek’s ultra-thin, organic Solar Film can be opaque or semi-transparent in a variety of colors for design purposes.

Dr. Thomas Bickl, vice president sales and product development for Heliatek GmbH, noted that Heliatek has made steady efficiency improvements in recent years, both on the lab scale and on production-ready films.

“In 2013, we obtained a third party certified world record of 12% STC efficiency on lab scale cells (4.35 cm²), and just recently we reached 7% efficiency on a 2m long module produced on our pilot line in Dresden,” Dr. Bickl said.

Michael Niggemann, chief technology officer for Eight19 Ltd., noted that the improvements and progress in the field of OPV are very encouraging on multiple levels.

“Organic photovoltaic modules are built up from a number of components, which, when combined, can all contribute to increased efficiency, reduced cost and longer life time,” Niggemann said. “Encapsulation materials have improved while the projected cost has dropped. A significant effort has been and is being dedicated to improving the stability of the photoactive stack, including electrodes and injection layers, which has resulted in champion efficiencies exceeding 10%.

“Central to Eight19’s development activities is the development of a low cost module architecture and related high volume manufacturing processes,” Niggemann added. “We have successfully demonstrated large roll-to-roll fabricated modules, and we are now in the process of developing solutions for customers.”

Advantages of OPVs

OPVs offer numerous advantages, beginning with the ability to produce lightweight, flexible materials with roll-to-roll processes. OPVs also efficiently collect energy in areas with low lighting. For example, Dr. Bickl said that Heliatek offers some unique advantages, such as its superior energy harvesting factor.

“Under low light conditions and at temperatures between 40°C and 75°C, our film generates substantially more energy per installed power than silicon or other thin film materials,” Dr. Bickl said. “Recent long term data from an outdoor test site points to 25% more energy generated than standard silicon modules (kWh/kWp). This would make very suitable for hot climates and non-optimal installation conditions.

“More important, however, are factors like our low weight (0.5 kg/m² compared to 15 kg/m² silicon), our ability to produce transparent solar cells at good efficiencies (latest 7% at 40% transparency) and geometrical flexibility due to our PET substrate,” he added. “Above all, our customers acknowledge that OPV is a truly green energy, with very short energy pay back times (less than six months) and no toxic or rare earth materials embedded.”

“OPV solar modules are light weight, flexible and robust,” Niggemann said. “High-volume roll-to-roll production is particularly suited to solution deposition of organic semiconductor materials and is key for low cost production. In combination with distinct properties such as high performance over a wide range of light intensities, the ability to produce semi-transparent modules of various colors opens up opportunities for new applications which existing solar technologies cannot address or are less well suited to.”

The European Union has funded MUJULIMA to solve some of the challenges facing OPV, including developing new materials, inks, cell architecture, light management technologies and inkjet printing process, enabling the production of high efficiency and long lifetime OPV.

Coordinated by TNO/Holst Centre, MUJULIMA will run until Dec. 31, 2016. MUJULIMA has nine members, including DisaSolar, which manufactures customized OPV modules through the use of digital inkjet printing processes and product integration. DisaSolar also produces flexible CIGS and thin film Si-based solar modules.

“OPV has several specific selling points to differentiate from other PV technologies: light weight, freedom in shape, substrate and color, semi-transparency and processing speed,” said Jan Gilot of TNO, who is MUJULIMA’s project coordinator. “The current status of OPV is around 10-12% efficiency on lab scale, with a lifetime varying between one to five years depending on the encapsulation.”

“OPV shows great features that differentiate it from the existing technologies, such as flexibility, low weight and freedom in the design and color,” Laurence Dassas, chief technology officer of DisaSolar, noted. “However, its efficiency and lifetime are still low.

Improvement in OPV performance by MUJULIMA is crucial for the development of DisaSolar through new markets and larger market share. Synthesis of new materials and ink formulations, optimization of the cell architecture and development of the inkjet process are required to achieve the goal of the project.”

Gilot said that MUJULIMA’s objective is an efficiency of 15% and a lifetime of 10 years. He said that the final step will be to bring the advances to the production line.

“The final goal is to achieve our objectives in efficiency and lifetime not only in the lab, but also prove it in production environment with striking demonstrators for indoor charging equipment, urban furniture and transport (e.g. bus, train, car),” Gilot concluded.

The Centre for Process Innovation (CPI) is also conducting research into OPV production. Alf Smith, business development manager for CPI, said that lower production costs for OPVs are another advantage, as is the environmentally friendly nature of the ingredients.

“One differentiator is the potential for the implementation of low cost and resource efficient manufacturing techniques,” Smith said. “OPVs can be coated at low temperatures and at high speed, meaning that they will be cheaper and easier to be mass produced than other technologies. In addition, OPVs contain no toxic metals, meaning that they are environmentally friendly throughout their lifecycle.”

Key Markets for OPV

Considering the advantages that OPV offers, the niche markets it could impact are many. As an example, while OPV would not be ideal for solar farms or rooftop installations due to lower efficiencies, its low weight and flexibility make it ideal for other end uses.

Edward Cahill, an analyst with Lux Research, sees smaller, niche markets as the best potential for thin-film PV suppliers. In a recent report, “Into the Niche: Putting a Magnifying Glass on PV’s Tiniest Markets,” Cahill placed these markets as a 1.2 gigawatt opportunity, led by BIPV.

“Market adoption has been limited and will remain small relative to conventional solar demand, but the niche application can be a profitable side business that supports a core business market,” Cahill said.

Lux Research believes that facades and roofing products such as solar shingles are a fast-growing segment for BIPV, followed by solar chargers.

BIPV is one area of great potential. Harvesting the sun’s rays in order to power buildings would be both sustainable and cost-efficient, once the equipment pays for itself. Of course, no one wants their windows to be full of wires or, worse yet, not be transparent.

New Energy Technologies, Inc. has created Solar Window, a patented technology that generates clean electricity on see-through glass windows, making use of the energy of natural sunlight and artificial sources such as fluorescent and LED lighting.

“Unlike conventional systems, SolarWindow can be applied to all four sides of tall towers, generating electricity using natural and artificial light conditions and even shaded areas,” said John Conklin, president and CEO of New Energy Technologies, Inc. “SolarWindow uses organic materials, which are dissolved into liquid, ideal for low-cost high-output manufacturing.”

These cells are sprayed on to see-through glass at room temperature using a novel, patent-pending process

Dr. Bickl noted that OPV can succeed in market segments where silicon is not suitable, such as BIPV, automotive and special applications, where low weight and other form factors are advantages.

“A German producer of overpressure halls will use our modules on top of his inflated structure to generate the power needed to drive the pressure compressor, thus reducing substantially the operating cost for his customers,” Dr. Bickl said. “No other PV technology could do this due to the unique combination of low weight and superior energy harvesting factor.”

Niggemann noted that new technologies most often find their way into large scale established markets through emerging markets.

“Sometimes these emerging markets can exceed the size of existing markets. Eight19 is focusing on a number of emerging markets rather than the traditional mainstream photovoltaic energy market,” Niggemann said.

“We see significant potential in a number of emerging markets,” Niggemann added. “The indoor energy harvesting market is growing as more technology is integrated in the built environment. Light is in most cases an effective source for energy indoors. Eight19’s OPV can play to its strengths with its outstanding low-light performance and easy lamination to surfaces to address this emerging market.”

The off-grid solar market is seen as an excellent opportunity, as solar chargers can replace kerosene or diesel as a means to provide electricity.

“We see off-grid solar as the next accessible, strongly growing market,” Niggemann noted. “Today some 1.3 billion people have no access to electricity, and this number is currently projected to barely change in the foreseeable future, with some 1.2 billion people globally still forecast to be without access to electricity in 2030.

“Traditional solar generation efforts have focused on replacing fossil fuel-based power generation for mainstream electrical applications (so-called ‘on-grid’ power),” he continued. “However, in countries where the distribution grid infrastructure itself is lacking, another market is rapidly growing for domestic and consumer applications that are not connected to electricity. Such devices are frequently powered by batteries, kerosene or diesel generators – all of which have a disproportionately high environmental impact as well as a high cost compared to standard on-grid electricity. In particular the robustness and the low weight of Eight19’s plastic solar provided at an affordable cost point is expected to make it highly attractive in off-grid applications ranging from phone charging to lighting and even communal installations.

“The building integrated market is also a promising long-term market,” Niggemann concluded. “In particular, the options of semi-transparency and choice in colors make OPV attractive for window and glass facade applications.”

“The development of organic photovoltaics with flexible form factors opens up a host of design opportunities and will lead to the creation of a range of electronic applications in key market sectors such as automotive, print and packaging, construction and healthcare,” Smith said. “The integration of conformable OPV increases the freedom for product designers to embed technology and functionality into their designs, creating the opportunity for new, innovative components that are wireless, smarter, interactive, conformable, thinner, lightweight, rugged and able to blend into our environment.

“In the future we have no doubt that flexible OPV will be produced in large areas and in high volumes, with extensive product lifetimes – properties ideal for innovative automotive/architectural applications,” Smith noted. “However, likewise with OLED, the short term value is to pursue niche applications where the technology is viable today.

“Organic photovoltaics will not only target existing markets, but will also lead to the creation of new markets and novel applications such as smart therapeutic bandages for managing and monitoring the recovery of wounds, wearable electronics for monitoring and improving athletic performance and highly efficient curved architectural solar power,” Smith added.