David Savastano, Editor11.14.16

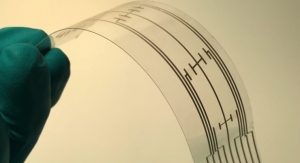

The flexible and printed electronics field is growing up. Products are moving into commercialization, with more items in the pipeline. Leading companies throughout the supply chain are reporting they are seeing gains being made in many markets.

Roy Bjorlin, commercial and strategic initiatives director, printed electronics at Sun Chemical, reports that Sun Chemical is seeing many opportunities for flexible and printed electronics in the marketplace.

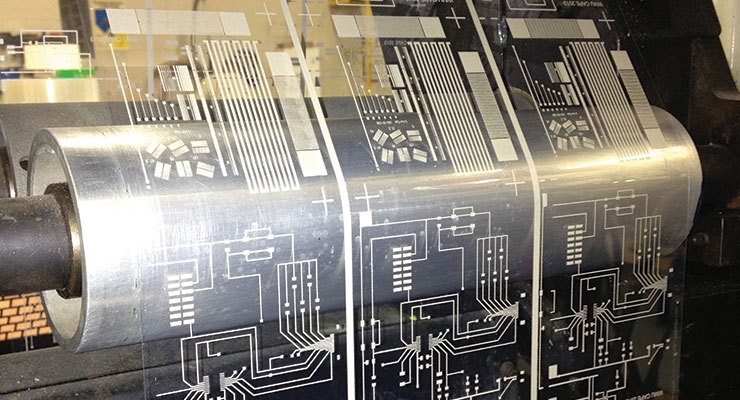

“The interest is increasingly high in adding electronics to everyday items including the wearables space, smart packaging and smart labels,” said Bjorlin. “This is creating demand to develop materials that can require flexibility and can also be processed in high speed using more non-traditional printing methods such as flexographic printing.”

Bill Cummings, SVP, corporate communications, Thin Film Electronics, said that Thinfilm has been successful in using its technology to help make products smart – from medical devices to luxury handbags to craft beer.

“We are particularly excited about conversations we’re having with leaders in the pharmaceuticals space,” Cummings added. “The potential for smart packaging on prescription and OTC products is tremendous, particularly as it relates to improving patient adherence and related outcomes.”

The initial forecasts for flexible and printed electronics did the industry no favors, as overhyped expectations set unattainable goals that were not attained, diminishing the field in the eyes of many.

“There is a lot less hype than when we started the company in 2010,” said David Britton of PST Sensors. “Printed and flexible electronics is no longer seen as a completely disruptive technology which will replace traditional electronics, but instead as a disruptive technology within the electronics space which complements existing tools and materials to offer a better solution. Printed temperature sensors are a very good example of this. Most successful or growing companies are just quietly getting on with the job.”

“Initially, there was a belief printed electronics would move quickly to offer better, cheaper solutions to the more traditional means of manufacturing in many markets,” added XENON Corporation CEO Lou Panico. “At this time, we have a better understanding the path for successful commercialization will extend longer.”

Thomas Kolbusch, VP for Coatema Coating Machinery GmbH, said Coatema is seeing new companies entering the market.

“The players change, so we see not only start-ups asking for equipment, also bigger players e.g. out of the packaging/converting business are much more interested,” said Kolbusch. “We are also seeing a bigger pull from user exhibitions like sportswear for wearables and medical applications. The increasing impact of the IoT and Industry 4.0 also has an impact. One breakthrough has be the integration of hybrids into the community, which can overcome red brick walls of the pure printed devices.”

TactoTek specializes in the field of 3D injection molded structural electronics, integrating printed electronics and discrete electronic components such as LEDs and ICs into a 3D injection molded structure while adding functionalities like lighting, printed sensors and antennas.

“Brands and OEMs are constantly seeking differentiation,” said Dave Rice, SVP marketing for TactoTek. “3D smart surfaces enable form factor and functional innovation.”

Promising Markets for Flexible and Printed Electronics

New applications are being developed daily for flexible and printed electronics. For example Panico pointed to sensors in automotive and aerospace industries as growing markets, while Kolbusch noted that sensors, energy harvesting, flexible display electrochromic films and wearables are promising markets for flexible and printed electronics.

“At Sun Chemical, we believe the drive towards the consumer at the item level, particularly when it comes to smart packaging and smart labels will become increasingly evident over the next few years,” said Bjorlin. “Much of our focus in R&D is geared towards the development of advanced materials able to be processed in high speed and that can be processed equally in the non-traditional convertor space that supports the consumer brands.”

Britton said that unique form factors are helping to drive new business.

“Long term, those markets where the new form factor enables a product which can’t be met by traditional electronics or non-electronics solutions are growing,” Britton said. “Obvious examples are IoE logistics (supply chain monitoring and management from producer to end consumer) and wearable technology (mainly health and fitness). These markets still need to be developed and are really being driven by a technology push, so it will take time.

“Short term, the growth markets are where the new form factor offers a significant advantage in terms of performance over traditional technologies,” Britton added. “Most examples for us at the moment are for advanced temperature sensing in the traditional IoT – manufacturing, process and instrument monitoring, but we are getting some traction in healthcare, logistics, and environmental monitoring.”

“TactoTek’s strongest market pull is from automotive, home appliances and wearable technology,” Rice said. “We also have strong interest for home automation, industrial controls, medical devices and other markets.”

Interesting Applications

There are numerous products being developed, although many are covered by non-disclosure agreements (NDAs). Throughout the supply chain, manufacturers are seeing interesting projects.

Panico said that XENON is developing low cost, benchtop R&D photonic sintering equipment with features typically found in higher-priced systems presently available to the printed electronics market.

“Driving this work is the requirement for improved tools to assist researchers, scientists and engineers in determining the precise parameters to control sintering of new copper nano inks,” Panico said. “Although these new designs are responding and meeting requests for lower cost equipment, features such as ease-of-use, configurability and high power are being included.”

Bjorlin said that Sun Chemical is working on several strategic projects including in mold electronics, 3D antenna and sensors.

“Our focus is in supporting a range of materials and process technologies that are driven towards enabling next generation applications,” said Bjorlin. “For example, we believe a robust nano materials portfolio will be an enabling materials technology and open pathways to producing material alternatives to a range of applications including display, switch technology, EMI/RFI shielding and lighting.”

Britton said that almost all of PST Sensors’ work these days is under NDA, but the most interesting projects are those that use temperature sensing to do something else.

“For example, we have just started a development contract for an international mining and minerals processing equipment supplier to develop a method of monitoring and predicting the useful life of some of their most important (and expensive) consumables,” Britton said.

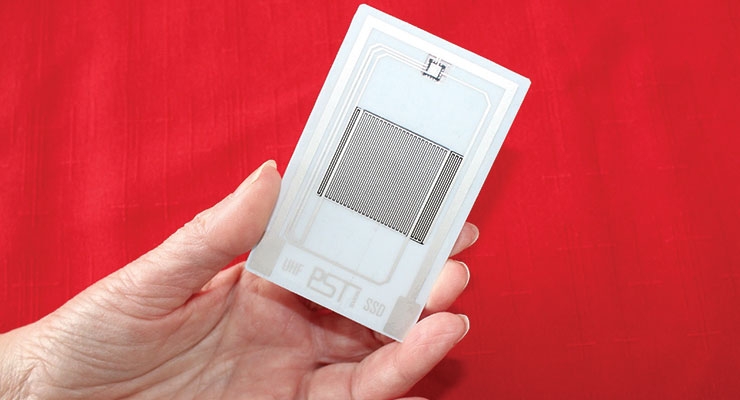

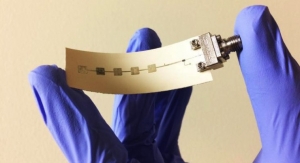

“Another project is with a consumer goods company to develop a high frequency temperature logger to monitor and control the manufacturing process in one of their major products produced internationally,” Britton added. “The demands for this tag are very unusual, but it is based around a credit card format generic passive UHF tag, which we now call the Kushushu Card, which we will be showing at the IDTechEx show.

“The Kushusu Card is a fully EPC Gen 2 compliant ISM 860-960 MHz passive RF read on demand sensor tag,” Britton noted. “It has no battery, a large area temperature sensor for sensitivity, and early versions have a read range of 3m, which compares favorably with an NFC tag. It is also the base of a system we are developing with a Scandinavian partner for fish and other fresh produce monitoring.”

Challenges Ahead

Even as successes are occurring, there are needs throughout the supply chain. On the equipment side, Panico said that providing an appealing argument for a transformation change in the roll-to-roll manufacturing process that will match emerging nano materials is the greatest challenge facing the industry.

“Accuracy in the operation, scaling in to bigger working width, stability of the inks being used and not enough sampling of product for new players in the market, specifically for wearables,” said Kolbusch.

“For us, the greatest challenge is in identifying the appropriate and compatible complementary technologies and then developing and scaling up the necessary hybrid manufacturing and processing,” Britton said. “Not everything can be assembled by traditional printing and converting techniques, and not all printing methods are fully compatible with each other. This is more so when it comes to advanced functional printing.”

Collaborating with brand owners is key to the industry’s future expansion.

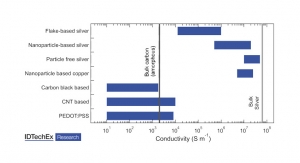

“Adoption is always a challenge,” said Bjorlin. “It’s clear that at the OEM level and in the case of smart packaging, the brands must be convinced that any innovation must enhance the device, must be competitive and must have a reliable manufacturing and global supply infrastructure to ensure a reliable supply of product. For example: nano materials and in particular nano Ag could very well enable significant advancements in printed electronics in applications ranging from photo voltaic to semi-conductor packaging. However, why hasn’t it become ubiquitous as a standard material?”

Expectations for Flexible and Printed Electronics

Overall, expectations for flexible and printed electronics are high for the short and near term.

“We want to generate around 50% of our sales volume with equipment for printed electronics and would like to move from pilot systems to real production environment, which is our core business in a lot of different markets,” said Kolbusch. “We see our traditional markets for production equipment growing together with PE like textiles, where we see more and more approaches for smart textiles.”

“It is very difficult to project which applications will grow the printed electronics market at this time,” said Panico. “Significant government as well as industry investments are required to drive innovation in both materials research as well as equipment designs.”

“We remain confident that advancement in materials technology will continue to drive the development of new applications particularly in the flexible space,” said Bjorlin. “Cost drives in photovoltaic, consumer interest in wearable and smart packaging as well as new and less expensive display and lighting will all be driving the demand for new materials and processes.”

Roy Bjorlin, commercial and strategic initiatives director, printed electronics at Sun Chemical, reports that Sun Chemical is seeing many opportunities for flexible and printed electronics in the marketplace.

“The interest is increasingly high in adding electronics to everyday items including the wearables space, smart packaging and smart labels,” said Bjorlin. “This is creating demand to develop materials that can require flexibility and can also be processed in high speed using more non-traditional printing methods such as flexographic printing.”

Bill Cummings, SVP, corporate communications, Thin Film Electronics, said that Thinfilm has been successful in using its technology to help make products smart – from medical devices to luxury handbags to craft beer.

“We are particularly excited about conversations we’re having with leaders in the pharmaceuticals space,” Cummings added. “The potential for smart packaging on prescription and OTC products is tremendous, particularly as it relates to improving patient adherence and related outcomes.”

The initial forecasts for flexible and printed electronics did the industry no favors, as overhyped expectations set unattainable goals that were not attained, diminishing the field in the eyes of many.

“There is a lot less hype than when we started the company in 2010,” said David Britton of PST Sensors. “Printed and flexible electronics is no longer seen as a completely disruptive technology which will replace traditional electronics, but instead as a disruptive technology within the electronics space which complements existing tools and materials to offer a better solution. Printed temperature sensors are a very good example of this. Most successful or growing companies are just quietly getting on with the job.”

“Initially, there was a belief printed electronics would move quickly to offer better, cheaper solutions to the more traditional means of manufacturing in many markets,” added XENON Corporation CEO Lou Panico. “At this time, we have a better understanding the path for successful commercialization will extend longer.”

Thomas Kolbusch, VP for Coatema Coating Machinery GmbH, said Coatema is seeing new companies entering the market.

“The players change, so we see not only start-ups asking for equipment, also bigger players e.g. out of the packaging/converting business are much more interested,” said Kolbusch. “We are also seeing a bigger pull from user exhibitions like sportswear for wearables and medical applications. The increasing impact of the IoT and Industry 4.0 also has an impact. One breakthrough has be the integration of hybrids into the community, which can overcome red brick walls of the pure printed devices.”

TactoTek specializes in the field of 3D injection molded structural electronics, integrating printed electronics and discrete electronic components such as LEDs and ICs into a 3D injection molded structure while adding functionalities like lighting, printed sensors and antennas.

“Brands and OEMs are constantly seeking differentiation,” said Dave Rice, SVP marketing for TactoTek. “3D smart surfaces enable form factor and functional innovation.”

Promising Markets for Flexible and Printed Electronics

New applications are being developed daily for flexible and printed electronics. For example Panico pointed to sensors in automotive and aerospace industries as growing markets, while Kolbusch noted that sensors, energy harvesting, flexible display electrochromic films and wearables are promising markets for flexible and printed electronics.

“At Sun Chemical, we believe the drive towards the consumer at the item level, particularly when it comes to smart packaging and smart labels will become increasingly evident over the next few years,” said Bjorlin. “Much of our focus in R&D is geared towards the development of advanced materials able to be processed in high speed and that can be processed equally in the non-traditional convertor space that supports the consumer brands.”

Britton said that unique form factors are helping to drive new business.

“Long term, those markets where the new form factor enables a product which can’t be met by traditional electronics or non-electronics solutions are growing,” Britton said. “Obvious examples are IoE logistics (supply chain monitoring and management from producer to end consumer) and wearable technology (mainly health and fitness). These markets still need to be developed and are really being driven by a technology push, so it will take time.

“Short term, the growth markets are where the new form factor offers a significant advantage in terms of performance over traditional technologies,” Britton added. “Most examples for us at the moment are for advanced temperature sensing in the traditional IoT – manufacturing, process and instrument monitoring, but we are getting some traction in healthcare, logistics, and environmental monitoring.”

“TactoTek’s strongest market pull is from automotive, home appliances and wearable technology,” Rice said. “We also have strong interest for home automation, industrial controls, medical devices and other markets.”

Interesting Applications

There are numerous products being developed, although many are covered by non-disclosure agreements (NDAs). Throughout the supply chain, manufacturers are seeing interesting projects.

Panico said that XENON is developing low cost, benchtop R&D photonic sintering equipment with features typically found in higher-priced systems presently available to the printed electronics market.

“Driving this work is the requirement for improved tools to assist researchers, scientists and engineers in determining the precise parameters to control sintering of new copper nano inks,” Panico said. “Although these new designs are responding and meeting requests for lower cost equipment, features such as ease-of-use, configurability and high power are being included.”

Bjorlin said that Sun Chemical is working on several strategic projects including in mold electronics, 3D antenna and sensors.

“Our focus is in supporting a range of materials and process technologies that are driven towards enabling next generation applications,” said Bjorlin. “For example, we believe a robust nano materials portfolio will be an enabling materials technology and open pathways to producing material alternatives to a range of applications including display, switch technology, EMI/RFI shielding and lighting.”

Britton said that almost all of PST Sensors’ work these days is under NDA, but the most interesting projects are those that use temperature sensing to do something else.

“For example, we have just started a development contract for an international mining and minerals processing equipment supplier to develop a method of monitoring and predicting the useful life of some of their most important (and expensive) consumables,” Britton said.

“Another project is with a consumer goods company to develop a high frequency temperature logger to monitor and control the manufacturing process in one of their major products produced internationally,” Britton added. “The demands for this tag are very unusual, but it is based around a credit card format generic passive UHF tag, which we now call the Kushushu Card, which we will be showing at the IDTechEx show.

“The Kushusu Card is a fully EPC Gen 2 compliant ISM 860-960 MHz passive RF read on demand sensor tag,” Britton noted. “It has no battery, a large area temperature sensor for sensitivity, and early versions have a read range of 3m, which compares favorably with an NFC tag. It is also the base of a system we are developing with a Scandinavian partner for fish and other fresh produce monitoring.”

Challenges Ahead

Even as successes are occurring, there are needs throughout the supply chain. On the equipment side, Panico said that providing an appealing argument for a transformation change in the roll-to-roll manufacturing process that will match emerging nano materials is the greatest challenge facing the industry.

“Accuracy in the operation, scaling in to bigger working width, stability of the inks being used and not enough sampling of product for new players in the market, specifically for wearables,” said Kolbusch.

“For us, the greatest challenge is in identifying the appropriate and compatible complementary technologies and then developing and scaling up the necessary hybrid manufacturing and processing,” Britton said. “Not everything can be assembled by traditional printing and converting techniques, and not all printing methods are fully compatible with each other. This is more so when it comes to advanced functional printing.”

Collaborating with brand owners is key to the industry’s future expansion.

“Adoption is always a challenge,” said Bjorlin. “It’s clear that at the OEM level and in the case of smart packaging, the brands must be convinced that any innovation must enhance the device, must be competitive and must have a reliable manufacturing and global supply infrastructure to ensure a reliable supply of product. For example: nano materials and in particular nano Ag could very well enable significant advancements in printed electronics in applications ranging from photo voltaic to semi-conductor packaging. However, why hasn’t it become ubiquitous as a standard material?”

Expectations for Flexible and Printed Electronics

Overall, expectations for flexible and printed electronics are high for the short and near term.

“We want to generate around 50% of our sales volume with equipment for printed electronics and would like to move from pilot systems to real production environment, which is our core business in a lot of different markets,” said Kolbusch. “We see our traditional markets for production equipment growing together with PE like textiles, where we see more and more approaches for smart textiles.”

“It is very difficult to project which applications will grow the printed electronics market at this time,” said Panico. “Significant government as well as industry investments are required to drive innovation in both materials research as well as equipment designs.”

“We remain confident that advancement in materials technology will continue to drive the development of new applications particularly in the flexible space,” said Bjorlin. “Cost drives in photovoltaic, consumer interest in wearable and smart packaging as well as new and less expensive display and lighting will all be driving the demand for new materials and processes.”