Dave Savastano, Editor03.07.19

Flexible, printed and hybrid electronics are making major inroads in numerous markets, and the automotive segment is one of the most promising. Whether it is sensors, OLED displays and lighting, in-mold electronics, printed heaters or other applications, there are plenty of opportunities ahead for flexible electronics.

During LOPEC 2018, Ashutosh Tomar, principal engineer (research) with Jaguar Land Rover (JLR) Research and Technology, talked about potential uses for printed electronics, including interiors, exteriors and energy harvesting.

“There is massive competition,” Tomar said. “We have to do something radical as we look forward in the future. The good news is there is printed electronics and four key areas where it can make an impact: A-surface features where customers interact; sensors; energy harvesting and storage; and ECUs (engine control units) and EDS (electrical distribution systems).

“With A-surfaces, the design and the electronics have to come together,” Tomar noted. “This will come soon enough with functional performance, creating something like shaped displays that was impossible before. There are areas where we are looking into. The first application saved 60% weight.”

There are a number of interesting advances already. Printed heaters have long been a staple of cars. OLED lighting appears on rear taillights for a few high-end BMW and Audi models, such as the OLED taillights on the Audi A8. They give designers the freedom to come up with new, creative looks. Osram-Continental, a JV between Osram and Continental, is a key player in that field.

Inside the car, displays also play a key role. Canatu is working with DENSO, a leading automotive interior specialist, on heaters. DENSO will be using Canatu’s CNB film manufacturing for heaters used in autonomous cars. DENSO has also invested $270 million in JOLED, which is working on printed OLED displays for cars.

Canatu and Continental have been working on a completely new type of transparent, 3D touch surfaces in automotive interiors, resulting in the world’s first touchscreen featuring a 3D-shaped touch surface. This HMI (human machine interface) innovation is enabled by stretchable Canatu CNB films and sensors. It was selected as one of CES 2018 Best of Innovation Awards Honoree in the “In-Vehicle Audio/Video” category and the Display Component of the Year 2018 Award of the Society for Information Display (SID).

“Our vision is that any surface can be smart. We have been working hard to meet and exceed the demanding needs of the next generation products,” said Juha Kokkonen, Canatu CEO. “The tactile sensing of our 3D shaped surfaces, such as buttons, sliders and switches – integrated to displays – decrease driver distraction, that is, the driver can use the controls effortlessly while keeping his focus on driving. Meanwhile, interiors are stylish and functional.”

John Voultos, VP business development for Sheldahl Flexible Technologies Inc., a Flex Company, noted that the automotive industry is readopting capacitive touch for a human-machine interface as the progress the industry has made in delivering a reliable touch circuit has grown leaps and bounds.

“Companies like Preh, Grupo Antolin, Yang Feng and Faurecia are some of the companies who are working to move this technology forward,” Voultos said. “Other applications that benefit from flexible electronics delivering form, fit, and function is LED for interior lighting. Shortly, Sheldahl Flexible working with a key LED provider will announce a key development using flexible circuits for high power applications.”

“We are doing all kinds of things in automotive, including brake pads and gaskets,” said Tekscan CTO Robert Podoloff. “Each of the applications we have taken on has led to another. For example, some people wanted to see how brake lines swelled; now our technology is being used in hybrid cars to look at batteries when they are charging to see if it is swelling when being overcharged.”

In-Mold ElectrOnics And The Automotive Market

In-mold electronics are an area where flexible and printed electronics are intersecting with the automotive market. Faurecia, another leader in automotive interiors, is developing consoles with TactoTek and is also investing in the company.

“Integrating electronics into 3D plastic structures, plastronics, is transforming vehicle interior design. Faurecia is investing in an ecosystem of plastronic companies, and TactoTek integrates those technologies into light, thin, functional solutions,” said David Weill, VP marketing and business development at Faurecia.

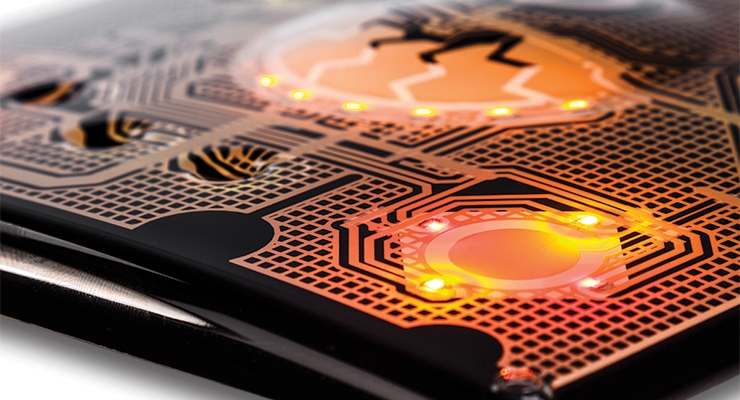

Dave Rice, SVP marketing at TactoTek, reported that there are many diverse use cases for TactoTek’s injection molded structural electronics (IMSE) solutions in automotive.

“The majority of our use cases today include three functional building blocks: circuitry, touch and lighting. Quite a few also add antennas and/or natural wood finishes. We can package those features in an injection molded structure that is lightweight, 3D, durable, and very thin,” Rice reported.

“The majority of the solutions we work on with our customers, OEMs and Tier 1/2 suppliers, are human-machine interface solutions for the interior,” Rice added. “These typically include printed circuitry, in-mold touch sensors and LEDs, and increasingly incorporate printed antennas for Bluetooth, NFC and Wi-Fi connectivity. With these building blocks – touch, lighting and connectivity – there are dozens of interior use cases within a vehicle. A few of the prominent use cases include turning cosmetic areas, such as vehicle trim, into smart surfaces with electronic functions; and a notable specific use case is overhead controls.”

Rice also noted that exterior use cases are emerging.

“For now, those tend to be simpler designs, and for good reason: exterior environmental performance requirements, particularly extended thermal cycling, are very challenging,” he pointed out. “Our IMSE technology stack that integrates printed electronics and electronic components inside of 3D injection molded plastics has been validated to the satisfaction of multiple OEMs and Tier 1 suppliers, including thermal cycling, thermal shock and high heat/humidity. I’m confident that we’ll see some big advances very soon.”

Flexible and Hybrid Electronics in Automobiles

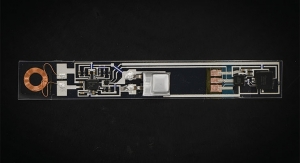

Automotive manufacturers are looking at ways to integrate new technologies that will save on costs and improve their customers’ experiences. Wilfried Bair, VP of engineering, NextFlex, noted that there is a multitude of opportunities for flexible hybrid electronics (FHE) in the automotive market.

“As an example, Ford is looking for improved functionality in autonomous vehicles and how to integrate sensing systems, and every gram you can take off counts,” Bair continued. “An autonomous vehicle draws a lot of power. With FHE, we address all these problems, including size, weight, and putting sensors into areas that don’t have much space. With smart surfaces, there is an expectation of functionality. In the future, touch surfaces will have no knobs or buttons.

“One sensing opportunity is ensuring that the vehicle works,” said Bair. “Wiring harnesses are bulky, heavy and highly complex, and we can print these conductors thus eliminating cables while increasing reliability. These FHE systems are also robust, as lower weight is more robust when it comes to G forces and vibrations.

“NextFlex has multiple projects with automotive companies,” Bair noted. “We are printing antennas on drone wings and aircraft parts and can easily adapt this to automotive body panels. Instead of my car key, I can have a wristband that can open a car door or trunk. In the future, the more electronics you have, the more they will disappear.”

“All major players (car manufacturers and Tier 1 suppliers) show solutions with printed electronics, in particular, touch sensors for HMI, enabled by 3D structural electronics, (3DMID or thermoforming),” said Klaus Hecker, managing director of the OE-A. “In addition, Audi showed the first product (e-tron) with an electronic side rear mirror including OLED display.”

“We are seeing strong interest from automotive OEMs and Tier 1 and Tier 2 suppliers,” said Raghu Das, IDTechEx CEO. “The main areas are user interfaces and interiors, such as in-mold electronics and flexible lighting. The next is thermal interface materials for power semiconductors and printed seat heaters. The third main area is bumper technologies, integrating sensors, lights and other components.”

“The driving trend for the use of printed electronics is increased freedom of design,” said Wolfgang Milldner of MSWtech. “This comes together with expected cost advantages in production. 3D formed HMI started with touch sensors, and now uses embedded light or embedded displays. I know several projects on their way to serial production, but not yet mass produced.”

Roy Bjorlin of RWB INT LLC said that sensors are increasingly making their way into the passenger compartment, although most are discrete devices. “Disappointingly, the adoption of in-mold electronics, which appeared to be a natural fit for automotive, has been slow to capture more than the imagination so far,” he added. “However, in-mold electronics may soon be finding a new foothold in the aerospace market.”

Materials manufacturers are seeing increasing opportunities in the automotive space.

“We continue to see opportunities develop for in-mold electronic applications for automotive,” said John Hannafin, global product manager, Sun Chemical Advanced Materials. “Applications for headlamp/tail lamp heaters, in-dash displays, and mechanical switch replacements are gaining traction. Sensors for hands-on/off steering and driver drowsiness improve safety and benefit from the novel materials and processes being developed for flexible hybrid electronics.”

Nick Skelton, marketing manager, Brewer Science, Inc., sees cost and design benefits for automotive companies.

“Manufacturers are looking for lower-cost integrated solutions that incorporate solid-state components for a traditional button and switch technologies,” Skelton said.

“Printed electronics are well positioned for automotive solutions,” Skelton added. “For example, the switching mechanisms can be printed directly into molded panels, thereby reducing component count. An added benefit of printed electronics is integrating discrete components and wiring harnesses into a single printed solution. This not only decreases component cost and count but also reduces labor cost in the assembly process.”

Chris Booher, chief marketing officer for ChemCubed, said that he is seeing several applications in automotive that are using silver conductive inks.

“Through advanced manufacturing research, there are several applications that are utilizing additive manufacturing with silver conductive inks,” Booher noted. “Digital inkjet printing for conductive circuitry provides not only prototypes but also the benefits of conductive trace printing directly on plastic parts and a multitude of other substrates.”

All told, there are excellent opportunities ahead for flexible electronics of all types in the automotive world.

“There are IMSE parts coming to market in the near future, in addition to the wearable component on the market today,” Rice observed. “Of course, the automotive market’s technology validation requirements and long product lifecycles can be challenging. However, now that our technology has been validated we have some use cases that are on a fast track to product integration.”

“We are extremely excited about the evolution the automotive industry is going through,” Canatu’s Kokkonen concluded. “There are almost no limits to what can be innovated together with our partners.”

During LOPEC 2018, Ashutosh Tomar, principal engineer (research) with Jaguar Land Rover (JLR) Research and Technology, talked about potential uses for printed electronics, including interiors, exteriors and energy harvesting.

“There is massive competition,” Tomar said. “We have to do something radical as we look forward in the future. The good news is there is printed electronics and four key areas where it can make an impact: A-surface features where customers interact; sensors; energy harvesting and storage; and ECUs (engine control units) and EDS (electrical distribution systems).

“With A-surfaces, the design and the electronics have to come together,” Tomar noted. “This will come soon enough with functional performance, creating something like shaped displays that was impossible before. There are areas where we are looking into. The first application saved 60% weight.”

There are a number of interesting advances already. Printed heaters have long been a staple of cars. OLED lighting appears on rear taillights for a few high-end BMW and Audi models, such as the OLED taillights on the Audi A8. They give designers the freedom to come up with new, creative looks. Osram-Continental, a JV between Osram and Continental, is a key player in that field.

Inside the car, displays also play a key role. Canatu is working with DENSO, a leading automotive interior specialist, on heaters. DENSO will be using Canatu’s CNB film manufacturing for heaters used in autonomous cars. DENSO has also invested $270 million in JOLED, which is working on printed OLED displays for cars.

Canatu and Continental have been working on a completely new type of transparent, 3D touch surfaces in automotive interiors, resulting in the world’s first touchscreen featuring a 3D-shaped touch surface. This HMI (human machine interface) innovation is enabled by stretchable Canatu CNB films and sensors. It was selected as one of CES 2018 Best of Innovation Awards Honoree in the “In-Vehicle Audio/Video” category and the Display Component of the Year 2018 Award of the Society for Information Display (SID).

“Our vision is that any surface can be smart. We have been working hard to meet and exceed the demanding needs of the next generation products,” said Juha Kokkonen, Canatu CEO. “The tactile sensing of our 3D shaped surfaces, such as buttons, sliders and switches – integrated to displays – decrease driver distraction, that is, the driver can use the controls effortlessly while keeping his focus on driving. Meanwhile, interiors are stylish and functional.”

John Voultos, VP business development for Sheldahl Flexible Technologies Inc., a Flex Company, noted that the automotive industry is readopting capacitive touch for a human-machine interface as the progress the industry has made in delivering a reliable touch circuit has grown leaps and bounds.

“Companies like Preh, Grupo Antolin, Yang Feng and Faurecia are some of the companies who are working to move this technology forward,” Voultos said. “Other applications that benefit from flexible electronics delivering form, fit, and function is LED for interior lighting. Shortly, Sheldahl Flexible working with a key LED provider will announce a key development using flexible circuits for high power applications.”

“We are doing all kinds of things in automotive, including brake pads and gaskets,” said Tekscan CTO Robert Podoloff. “Each of the applications we have taken on has led to another. For example, some people wanted to see how brake lines swelled; now our technology is being used in hybrid cars to look at batteries when they are charging to see if it is swelling when being overcharged.”

In-Mold ElectrOnics And The Automotive Market

In-mold electronics are an area where flexible and printed electronics are intersecting with the automotive market. Faurecia, another leader in automotive interiors, is developing consoles with TactoTek and is also investing in the company.

“Integrating electronics into 3D plastic structures, plastronics, is transforming vehicle interior design. Faurecia is investing in an ecosystem of plastronic companies, and TactoTek integrates those technologies into light, thin, functional solutions,” said David Weill, VP marketing and business development at Faurecia.

Dave Rice, SVP marketing at TactoTek, reported that there are many diverse use cases for TactoTek’s injection molded structural electronics (IMSE) solutions in automotive.

“The majority of our use cases today include three functional building blocks: circuitry, touch and lighting. Quite a few also add antennas and/or natural wood finishes. We can package those features in an injection molded structure that is lightweight, 3D, durable, and very thin,” Rice reported.

“The majority of the solutions we work on with our customers, OEMs and Tier 1/2 suppliers, are human-machine interface solutions for the interior,” Rice added. “These typically include printed circuitry, in-mold touch sensors and LEDs, and increasingly incorporate printed antennas for Bluetooth, NFC and Wi-Fi connectivity. With these building blocks – touch, lighting and connectivity – there are dozens of interior use cases within a vehicle. A few of the prominent use cases include turning cosmetic areas, such as vehicle trim, into smart surfaces with electronic functions; and a notable specific use case is overhead controls.”

Rice also noted that exterior use cases are emerging.

“For now, those tend to be simpler designs, and for good reason: exterior environmental performance requirements, particularly extended thermal cycling, are very challenging,” he pointed out. “Our IMSE technology stack that integrates printed electronics and electronic components inside of 3D injection molded plastics has been validated to the satisfaction of multiple OEMs and Tier 1 suppliers, including thermal cycling, thermal shock and high heat/humidity. I’m confident that we’ll see some big advances very soon.”

Flexible and Hybrid Electronics in Automobiles

Automotive manufacturers are looking at ways to integrate new technologies that will save on costs and improve their customers’ experiences. Wilfried Bair, VP of engineering, NextFlex, noted that there is a multitude of opportunities for flexible hybrid electronics (FHE) in the automotive market.

“As an example, Ford is looking for improved functionality in autonomous vehicles and how to integrate sensing systems, and every gram you can take off counts,” Bair continued. “An autonomous vehicle draws a lot of power. With FHE, we address all these problems, including size, weight, and putting sensors into areas that don’t have much space. With smart surfaces, there is an expectation of functionality. In the future, touch surfaces will have no knobs or buttons.

“One sensing opportunity is ensuring that the vehicle works,” said Bair. “Wiring harnesses are bulky, heavy and highly complex, and we can print these conductors thus eliminating cables while increasing reliability. These FHE systems are also robust, as lower weight is more robust when it comes to G forces and vibrations.

“NextFlex has multiple projects with automotive companies,” Bair noted. “We are printing antennas on drone wings and aircraft parts and can easily adapt this to automotive body panels. Instead of my car key, I can have a wristband that can open a car door or trunk. In the future, the more electronics you have, the more they will disappear.”

“All major players (car manufacturers and Tier 1 suppliers) show solutions with printed electronics, in particular, touch sensors for HMI, enabled by 3D structural electronics, (3DMID or thermoforming),” said Klaus Hecker, managing director of the OE-A. “In addition, Audi showed the first product (e-tron) with an electronic side rear mirror including OLED display.”

“We are seeing strong interest from automotive OEMs and Tier 1 and Tier 2 suppliers,” said Raghu Das, IDTechEx CEO. “The main areas are user interfaces and interiors, such as in-mold electronics and flexible lighting. The next is thermal interface materials for power semiconductors and printed seat heaters. The third main area is bumper technologies, integrating sensors, lights and other components.”

“The driving trend for the use of printed electronics is increased freedom of design,” said Wolfgang Milldner of MSWtech. “This comes together with expected cost advantages in production. 3D formed HMI started with touch sensors, and now uses embedded light or embedded displays. I know several projects on their way to serial production, but not yet mass produced.”

Roy Bjorlin of RWB INT LLC said that sensors are increasingly making their way into the passenger compartment, although most are discrete devices. “Disappointingly, the adoption of in-mold electronics, which appeared to be a natural fit for automotive, has been slow to capture more than the imagination so far,” he added. “However, in-mold electronics may soon be finding a new foothold in the aerospace market.”

Materials manufacturers are seeing increasing opportunities in the automotive space.

“We continue to see opportunities develop for in-mold electronic applications for automotive,” said John Hannafin, global product manager, Sun Chemical Advanced Materials. “Applications for headlamp/tail lamp heaters, in-dash displays, and mechanical switch replacements are gaining traction. Sensors for hands-on/off steering and driver drowsiness improve safety and benefit from the novel materials and processes being developed for flexible hybrid electronics.”

Nick Skelton, marketing manager, Brewer Science, Inc., sees cost and design benefits for automotive companies.

“Manufacturers are looking for lower-cost integrated solutions that incorporate solid-state components for a traditional button and switch technologies,” Skelton said.

“Printed electronics are well positioned for automotive solutions,” Skelton added. “For example, the switching mechanisms can be printed directly into molded panels, thereby reducing component count. An added benefit of printed electronics is integrating discrete components and wiring harnesses into a single printed solution. This not only decreases component cost and count but also reduces labor cost in the assembly process.”

Chris Booher, chief marketing officer for ChemCubed, said that he is seeing several applications in automotive that are using silver conductive inks.

“Through advanced manufacturing research, there are several applications that are utilizing additive manufacturing with silver conductive inks,” Booher noted. “Digital inkjet printing for conductive circuitry provides not only prototypes but also the benefits of conductive trace printing directly on plastic parts and a multitude of other substrates.”

All told, there are excellent opportunities ahead for flexible electronics of all types in the automotive world.

“There are IMSE parts coming to market in the near future, in addition to the wearable component on the market today,” Rice observed. “Of course, the automotive market’s technology validation requirements and long product lifecycles can be challenging. However, now that our technology has been validated we have some use cases that are on a fast track to product integration.”

“We are extremely excited about the evolution the automotive industry is going through,” Canatu’s Kokkonen concluded. “There are almost no limits to what can be innovated together with our partners.”