David Savastano, Editor09.22.21

There is a lot of R&D and product development that is occurring in the field of flexible and printed electronics, as well as some commercialization. Industry leaders say they are seeing much in the way of commercialization of these new products.

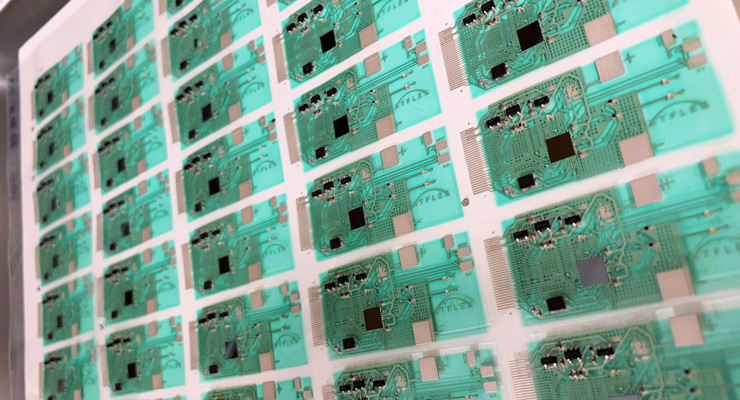

“We see a great interest in wearables and medical devices,” said Janos Veres, director of engineering at NextFlex. “There are many innovative developments in this space by both large and small companies, as well as startups. There is a natural fit for devices to conform to the body of the wearer and this might include customization to the person. Clearly, the range of functions and use cases being explored is extremely broad, which is another benefit of some of the digital techniques we and other players use to fabricate flexible electronics.

“We see a need for a great deal of iteration to arrive to the right form factor and convenience,” Veres continued. “It is all driven by the end user and we all must learn what makes sense most for user experience. Another important area, albeit in smaller volume, is specialist RF antennae and sensor arrays for aerial, naval and ground vehicles.”

Klaus Hecker, managing director of the OE-A, believes that “innovation is stronger than ever,” with the automotive market leading the way.

“There is an interesting development happening, and more and more PE products are ready to enter the market,” said Hecker. “The trend from ‘technology push’ to ‘market pull’ defined by the needs of the end users has continued over the last years. Medical/ pharma got a big boost also, due to corona. These markets have been big topics at LOPEC 2021.”

Wolfgang Mildner of msw tech said that it took a lot of R&D efforts and time to achieve commercialization levels.

“Some of the products which are coming to the market are small revolutions, e.g. the transformation from push buttons to smart surfaces,” Mildner continued. “We talk not only about new products, but also new manufacturing and integration processes, which were needed. This needs development and it took time to reach acceptable yield levels.”

Dr. Matthew Dyson is a technology analyst at IDTechEx, covering all aspects and applications of printed/flexible electronics. He reported that IDTechEx is seeing increased commercialization of new products, although in many cases only part of the electronic system is printed/flexible.

“Examples in the healthcare sector include e-textiles that provide electrical stimulation and disposable printed pressure sensors for dental characterization,” said Dr. Dyson. “Film-insert molding, closely related to IME, is also increasingly deployed in vehicles to provide capacitive switching. Printed capacitive touch sensors are also soon to be employed in mass-market furniture.”

Khasha Ghaffarzadeh, CEO of TechBlick, a year-round event series with more than 350+ analyst selected live online presentations and 10-plus masterclasses, noted that printed, flexible, and hybrid electronics is extremely diverse.

“For example, one can find conductive pastes in baby diapers as well as precision missiles. There are many applications now in production and many more on the horizon.”

Ghaffarzadeh highlighted some interesting emerging applications, including electronic packaging, where conductive pastes have been used in via filling for some years, and now they have an excellent shot at package-level EMI shielding.

“Interestingly, companies are printing many-layered complex RDLs (redistribution layers) for prototyping purposes,” said Ghaffarzadeh. “This is an exciting area as I think there is good potential to narrow the linewidths using the latest sub-micron printing techniques.”

MicroLEDs is also an interesting early-stage development in displays and lighting.

“In displays, printing can compete with PVDs,” Ghaffarzadeh said. “The idea is that a large substrate needs to be metallized to provide the interconnects for the picked- and-placed LEDs. Interestingly, printing could also cover the edges of the substrate to create a path from the front to the back side without needing a via through the glass. In lighting, there is good movement on R2R printing of LED-based large-area lighting.”

Continuous monitoring and skin patches are also an opportunity. “Of course, glucose test strips were always one of the largest markets for printed electronics,” Ghaffarzadeh said. “Pressure on margins and the rise of continuous glucose monitoring (CGMs) put that market under pressure. However, CGMs itself are now a very interesting opportunity for printed electronics. In general, electronic skin patches, medical electrodes and continuous healthcare monitoring biosensors are hot areas.”

“Smart packaging has been the dream for long, but cost and also complexity of initial solutions held the market back,” said Ghaffarzadeh. “However, now there is good progress on medication adherence using smart packages. In general, the idea is that taking the pills will break a circuit which can be monitored. What I like here is that this has evolved into a full solution including rigid electronics, printed electronics, software, and a viable business model. In the long term, say in five to seven years, the packaging will evolve beyond simple circuits to include flexible hybrid electronics.

“Another field in smart packaging is in precision printed transparent NFCs and RFID tags,” Ghaffarzadeh added. “Being transparent means that they can be printed onto graphics, thus not wasting value real estate on the package. There are firms here that R2R print NFCs with few micron meter linewidths. Again, here too, the firms are offering a full solution including printing as well as secure blockchain-based track and tracing.”

“In-mold electronics is finally on the up,” Ghaffarzadeh observed. “There have been sporadic applications in consumer electronics and also in automotive LED light covers for defrosting. Now, we hear that the industry is not far from success in the interior of cars as well. In general, there is good maturity so we recommend keeping an eye out on this.”

Hecker said that healthcare, automotive, consumer electronics, and building and architecture are key markets, adding that there is great potential in IoT and in printing and packaging.

Mildner said that sensors are the strongest opportunity.

“It started with the seat occupancy and moved to touch sensors (especially capacitive touch), which is a strong opportunity for flexible electronics still by substituting conventional human machine interfaces by smart surfaces,” Mildner noted. “Additional to sensors, we will see printed integrated heating structures and integrated lighting (as a hybrid approach with LED or with OLED devices).”

Dr. Dyson said it should be noted in some areas printed/flexible electronics is already a resounding commercial success, such as printing conductive inks onto PV panels, force sensitive resistors for car occupancy sensors, OLED displays and glucose test strips.

“We see the greatest opportunities in flexible OLED displays, which are already commercialized in smartphones,” said Dr. Dyson. “Wearable/healthcare technology, especially electronic skin patches, are currently attracting extensive amounts of interest and investment. There are also opportunities in automotive and defense manufacturing, with the light weight and conformality (rather than repeated flexing) especially advantageous.”

“Let’s focus on flexible hybrid electronics as I think here the pieces of the puzzle are coming together,” said Ghaffarzadeh. “There is good movement on flexible ICs. There are thinned silicon ICs which can be more powerful functionality-wise, and there are natively flexible ICs which are on older lithographic nodes but are also much lower cost. These will remedy the classic limitations with printed transistors and printed logic. In parallel, there is fantastic progress on R2R. The bottleneck here is R2R pick and place, but I feel the synergies with microLEDs and other industries will drive this forward. In the future, we will go well beyond RFDIs and NFCs, which can be considered as the simplest forms of flexible hybrid electronics.”

Veres said that a simplified segmentation of markets would probably start with medical wearables, automotive,and aerospace, as well as defense applications, adding that these are all potentially high value applications and they offer unique design freedoms.

“As the technology matures, it will address lower cost points for edge-of-IoT applications such as asset tracking, structural health monitoring, infrastructure and agricultural sensors,” added Veres. “Ultimately, we do see flexible hybrid electronics, or FHE as we call it, impacting mainstream electronics everywhere. FHE also enables new trajectories of electronics packaging, in a sense that thinned bare dies get gradually incorporated in the fabric of multilayer boards and more and more discrete components becoming monolithically integrated in the circuit.”

Challenges for Flexible Electronics

Even with the gains being made in flexible electronics, there are key needs that will have to be addressed.

“Entering the automotive market has quite a long lead time, so you need long term partners to develop new applications,” Hecker said. “In addition, product reliability, cost and availability second source are key to enter this market. But automotive companies are looking for new and innovative products to integrate to differentiate from their competitors and the revolution of the automotive industry due to trends like autonomous driving and electro mobility open new opportunities to enter this market.”

“Standardization is needed to minimize the efforts,” Mildner said. “Qualification and test methods for this new type of functional elements need to be developed and used, as the mechanical stress of this elements is challenging.”

“In my view the key step will be increased adoption of flexible electronics by contract manufacturers, which enable the technology to be applied to much higher volume applications,” said Dr. Dyson. “This will require greater clarity around standards and material parameters. For example, high volume manufacturers would like conductive inks from different manufacturers to be easily interchangeable to reduce supply-chain risk, but this is not generally the case at present. Longer, rigorous trials to demonstrate long term durability, for example ensuring functionality is maintained after multiple washing/stretching/flexing cycles e-textiles, are also likely to be required. These should ideally apply to the entire electronics system, rather than just individual components, so will require extensive collaboration between manufacturers.”

“I believe that the market is already successful,” said Ghaffarzadeh. “In many cases, it is the simpler solutions that are already commercial. So, one advice is always keep it simple. I think the design flow and also the foundry ecosystem is now much better established, which is helping companies translate ideas and designs into products. This was a real challenge in the past as the OEMs had to take on too many responsibilities.”

Veres said that FHE today often relies on materials, tools and processes that were developed for conventional electronics.

“We need interconnect materials that can withstand bending and strain, and some really good progress has been made in this area,” Veres noted. “We also need conductive materials that can be printed easily and cured at low temperatures to be compatible with a broad variety of plastics. We also need to make bare silicon chips amenable to easier integration with printed traces. This can start with the low hanging fruit of edge-of-IoT deployments of moderate complexity.

“We also need tools that can build multilayer circuits layer by layer additively, often in conjunction with building the structure of the part,” Veres observed. “Some of these challenges are akin to those of 3D printing. The technology can enable many applications but to drive it we need to work on either niche, high value use cases or spot a ‘killer app’ in a large market.”

Flexible Electronics and Everyday Life

It is clear that flexible electronics is part of our daily lives, even if they aren’t visible.

“Flexible electronics are already in our lives but it’s not visible (e.g. the seat occupancy sensors),” Mildner said. “It will be in every human interface of the future. And in the future it will be integrated in intelligent clothes or patches as a sensor to support our daily live and wellbeing.”

“At IDTechEx, we see greater integration as the key transition in electronics,” Dr. Dyson said. “Rather than thinking of electronics as something separate that a device must be designed around, electronics will increasingly become an integral part of objects that we interact with. Examples include smart floors, walls, windows and furniture, all of which will combine HMI functionality with the ability to send and receive data. Packaging and clothing will increasingly contain electronics, offering added functionality such as interaction with household appliances and biometric monitoring, respectively. Flexible electronics is well positioned to facilitate this trend, due to its reduced weight, conformality and potential for low-cost manufacturing.”

Veres noted that NextFlex’s focus is FHE, which means a new integration trajectory for electronics.

“This is already happening in wearables and certain transportation applications,” added Veres. “Both are driven by design freedom. We believe once we establish FHE in a robust way, we will see it flourish in all types of consumer devices in everyday life. It will get incorporated into clothing – an application we are exploring together with two other US Manufacturing Institutes, AFFOA and ARM.

“The first, AFFOA is focusing on advanced functional fibers and fabrics,” continued Veres. “ARM is exploring robotics and automation. This type of collaboration will be the key to be able to estimate, foresee and predict the future well enough. The next frontier for electronics integration is ‘freeing electronics from the box’, which is an exciting vision. It is about integrating function with form in entirely new ways. It could mean phones you might wrap around your wrist, or thinner computers that are less prone to break.

"It will also pave the way for creative people to dream up new features for everyday objects we could not possibly imagine today. Some time ago we could not envisage a watch looking after one’s health (besides telling the time), or your car’s dashboard responding to your fingerprint anywhere you touch it. From our vantage point, fascinating times are ahead.”

“Printed electronics is everywhere - you can find it in your car, in baby diapers, in ICs, in mobile phones, in electronic packages, in medical packages, in washing machines and other white goods, in some shirts and textiles, in medical electrodes, in displays, in solar cells, and so on. I think people should recognize and celebrate the amazing diversity of printed electronics more. This diversity never ceases to impress me,”

Ghaffarzadeh concluded.

“We see a great interest in wearables and medical devices,” said Janos Veres, director of engineering at NextFlex. “There are many innovative developments in this space by both large and small companies, as well as startups. There is a natural fit for devices to conform to the body of the wearer and this might include customization to the person. Clearly, the range of functions and use cases being explored is extremely broad, which is another benefit of some of the digital techniques we and other players use to fabricate flexible electronics.

“We see a need for a great deal of iteration to arrive to the right form factor and convenience,” Veres continued. “It is all driven by the end user and we all must learn what makes sense most for user experience. Another important area, albeit in smaller volume, is specialist RF antennae and sensor arrays for aerial, naval and ground vehicles.”

Klaus Hecker, managing director of the OE-A, believes that “innovation is stronger than ever,” with the automotive market leading the way.

“There is an interesting development happening, and more and more PE products are ready to enter the market,” said Hecker. “The trend from ‘technology push’ to ‘market pull’ defined by the needs of the end users has continued over the last years. Medical/ pharma got a big boost also, due to corona. These markets have been big topics at LOPEC 2021.”

Wolfgang Mildner of msw tech said that it took a lot of R&D efforts and time to achieve commercialization levels.

“Some of the products which are coming to the market are small revolutions, e.g. the transformation from push buttons to smart surfaces,” Mildner continued. “We talk not only about new products, but also new manufacturing and integration processes, which were needed. This needs development and it took time to reach acceptable yield levels.”

Dr. Matthew Dyson is a technology analyst at IDTechEx, covering all aspects and applications of printed/flexible electronics. He reported that IDTechEx is seeing increased commercialization of new products, although in many cases only part of the electronic system is printed/flexible.

“Examples in the healthcare sector include e-textiles that provide electrical stimulation and disposable printed pressure sensors for dental characterization,” said Dr. Dyson. “Film-insert molding, closely related to IME, is also increasingly deployed in vehicles to provide capacitive switching. Printed capacitive touch sensors are also soon to be employed in mass-market furniture.”

Khasha Ghaffarzadeh, CEO of TechBlick, a year-round event series with more than 350+ analyst selected live online presentations and 10-plus masterclasses, noted that printed, flexible, and hybrid electronics is extremely diverse.

“For example, one can find conductive pastes in baby diapers as well as precision missiles. There are many applications now in production and many more on the horizon.”

Ghaffarzadeh highlighted some interesting emerging applications, including electronic packaging, where conductive pastes have been used in via filling for some years, and now they have an excellent shot at package-level EMI shielding.

“Interestingly, companies are printing many-layered complex RDLs (redistribution layers) for prototyping purposes,” said Ghaffarzadeh. “This is an exciting area as I think there is good potential to narrow the linewidths using the latest sub-micron printing techniques.”

MicroLEDs is also an interesting early-stage development in displays and lighting.

“In displays, printing can compete with PVDs,” Ghaffarzadeh said. “The idea is that a large substrate needs to be metallized to provide the interconnects for the picked- and-placed LEDs. Interestingly, printing could also cover the edges of the substrate to create a path from the front to the back side without needing a via through the glass. In lighting, there is good movement on R2R printing of LED-based large-area lighting.”

Continuous monitoring and skin patches are also an opportunity. “Of course, glucose test strips were always one of the largest markets for printed electronics,” Ghaffarzadeh said. “Pressure on margins and the rise of continuous glucose monitoring (CGMs) put that market under pressure. However, CGMs itself are now a very interesting opportunity for printed electronics. In general, electronic skin patches, medical electrodes and continuous healthcare monitoring biosensors are hot areas.”

“Smart packaging has been the dream for long, but cost and also complexity of initial solutions held the market back,” said Ghaffarzadeh. “However, now there is good progress on medication adherence using smart packages. In general, the idea is that taking the pills will break a circuit which can be monitored. What I like here is that this has evolved into a full solution including rigid electronics, printed electronics, software, and a viable business model. In the long term, say in five to seven years, the packaging will evolve beyond simple circuits to include flexible hybrid electronics.

“Another field in smart packaging is in precision printed transparent NFCs and RFID tags,” Ghaffarzadeh added. “Being transparent means that they can be printed onto graphics, thus not wasting value real estate on the package. There are firms here that R2R print NFCs with few micron meter linewidths. Again, here too, the firms are offering a full solution including printing as well as secure blockchain-based track and tracing.”

“In-mold electronics is finally on the up,” Ghaffarzadeh observed. “There have been sporadic applications in consumer electronics and also in automotive LED light covers for defrosting. Now, we hear that the industry is not far from success in the interior of cars as well. In general, there is good maturity so we recommend keeping an eye out on this.”

Hecker said that healthcare, automotive, consumer electronics, and building and architecture are key markets, adding that there is great potential in IoT and in printing and packaging.

Mildner said that sensors are the strongest opportunity.

“It started with the seat occupancy and moved to touch sensors (especially capacitive touch), which is a strong opportunity for flexible electronics still by substituting conventional human machine interfaces by smart surfaces,” Mildner noted. “Additional to sensors, we will see printed integrated heating structures and integrated lighting (as a hybrid approach with LED or with OLED devices).”

Dr. Dyson said it should be noted in some areas printed/flexible electronics is already a resounding commercial success, such as printing conductive inks onto PV panels, force sensitive resistors for car occupancy sensors, OLED displays and glucose test strips.

“We see the greatest opportunities in flexible OLED displays, which are already commercialized in smartphones,” said Dr. Dyson. “Wearable/healthcare technology, especially electronic skin patches, are currently attracting extensive amounts of interest and investment. There are also opportunities in automotive and defense manufacturing, with the light weight and conformality (rather than repeated flexing) especially advantageous.”

“Let’s focus on flexible hybrid electronics as I think here the pieces of the puzzle are coming together,” said Ghaffarzadeh. “There is good movement on flexible ICs. There are thinned silicon ICs which can be more powerful functionality-wise, and there are natively flexible ICs which are on older lithographic nodes but are also much lower cost. These will remedy the classic limitations with printed transistors and printed logic. In parallel, there is fantastic progress on R2R. The bottleneck here is R2R pick and place, but I feel the synergies with microLEDs and other industries will drive this forward. In the future, we will go well beyond RFDIs and NFCs, which can be considered as the simplest forms of flexible hybrid electronics.”

Veres said that a simplified segmentation of markets would probably start with medical wearables, automotive,and aerospace, as well as defense applications, adding that these are all potentially high value applications and they offer unique design freedoms.

“As the technology matures, it will address lower cost points for edge-of-IoT applications such as asset tracking, structural health monitoring, infrastructure and agricultural sensors,” added Veres. “Ultimately, we do see flexible hybrid electronics, or FHE as we call it, impacting mainstream electronics everywhere. FHE also enables new trajectories of electronics packaging, in a sense that thinned bare dies get gradually incorporated in the fabric of multilayer boards and more and more discrete components becoming monolithically integrated in the circuit.”

Challenges for Flexible Electronics

Even with the gains being made in flexible electronics, there are key needs that will have to be addressed.

“Entering the automotive market has quite a long lead time, so you need long term partners to develop new applications,” Hecker said. “In addition, product reliability, cost and availability second source are key to enter this market. But automotive companies are looking for new and innovative products to integrate to differentiate from their competitors and the revolution of the automotive industry due to trends like autonomous driving and electro mobility open new opportunities to enter this market.”

“Standardization is needed to minimize the efforts,” Mildner said. “Qualification and test methods for this new type of functional elements need to be developed and used, as the mechanical stress of this elements is challenging.”

“In my view the key step will be increased adoption of flexible electronics by contract manufacturers, which enable the technology to be applied to much higher volume applications,” said Dr. Dyson. “This will require greater clarity around standards and material parameters. For example, high volume manufacturers would like conductive inks from different manufacturers to be easily interchangeable to reduce supply-chain risk, but this is not generally the case at present. Longer, rigorous trials to demonstrate long term durability, for example ensuring functionality is maintained after multiple washing/stretching/flexing cycles e-textiles, are also likely to be required. These should ideally apply to the entire electronics system, rather than just individual components, so will require extensive collaboration between manufacturers.”

“I believe that the market is already successful,” said Ghaffarzadeh. “In many cases, it is the simpler solutions that are already commercial. So, one advice is always keep it simple. I think the design flow and also the foundry ecosystem is now much better established, which is helping companies translate ideas and designs into products. This was a real challenge in the past as the OEMs had to take on too many responsibilities.”

Veres said that FHE today often relies on materials, tools and processes that were developed for conventional electronics.

“We need interconnect materials that can withstand bending and strain, and some really good progress has been made in this area,” Veres noted. “We also need conductive materials that can be printed easily and cured at low temperatures to be compatible with a broad variety of plastics. We also need to make bare silicon chips amenable to easier integration with printed traces. This can start with the low hanging fruit of edge-of-IoT deployments of moderate complexity.

“We also need tools that can build multilayer circuits layer by layer additively, often in conjunction with building the structure of the part,” Veres observed. “Some of these challenges are akin to those of 3D printing. The technology can enable many applications but to drive it we need to work on either niche, high value use cases or spot a ‘killer app’ in a large market.”

Flexible Electronics and Everyday Life

It is clear that flexible electronics is part of our daily lives, even if they aren’t visible.

“Flexible electronics are already in our lives but it’s not visible (e.g. the seat occupancy sensors),” Mildner said. “It will be in every human interface of the future. And in the future it will be integrated in intelligent clothes or patches as a sensor to support our daily live and wellbeing.”

“At IDTechEx, we see greater integration as the key transition in electronics,” Dr. Dyson said. “Rather than thinking of electronics as something separate that a device must be designed around, electronics will increasingly become an integral part of objects that we interact with. Examples include smart floors, walls, windows and furniture, all of which will combine HMI functionality with the ability to send and receive data. Packaging and clothing will increasingly contain electronics, offering added functionality such as interaction with household appliances and biometric monitoring, respectively. Flexible electronics is well positioned to facilitate this trend, due to its reduced weight, conformality and potential for low-cost manufacturing.”

Veres noted that NextFlex’s focus is FHE, which means a new integration trajectory for electronics.

“This is already happening in wearables and certain transportation applications,” added Veres. “Both are driven by design freedom. We believe once we establish FHE in a robust way, we will see it flourish in all types of consumer devices in everyday life. It will get incorporated into clothing – an application we are exploring together with two other US Manufacturing Institutes, AFFOA and ARM.

“The first, AFFOA is focusing on advanced functional fibers and fabrics,” continued Veres. “ARM is exploring robotics and automation. This type of collaboration will be the key to be able to estimate, foresee and predict the future well enough. The next frontier for electronics integration is ‘freeing electronics from the box’, which is an exciting vision. It is about integrating function with form in entirely new ways. It could mean phones you might wrap around your wrist, or thinner computers that are less prone to break.

"It will also pave the way for creative people to dream up new features for everyday objects we could not possibly imagine today. Some time ago we could not envisage a watch looking after one’s health (besides telling the time), or your car’s dashboard responding to your fingerprint anywhere you touch it. From our vantage point, fascinating times are ahead.”

“Printed electronics is everywhere - you can find it in your car, in baby diapers, in ICs, in mobile phones, in electronic packages, in medical packages, in washing machines and other white goods, in some shirts and textiles, in medical electrodes, in displays, in solar cells, and so on. I think people should recognize and celebrate the amazing diversity of printed electronics more. This diversity never ceases to impress me,”

Ghaffarzadeh concluded.