Tony Sun, Lux Research10.12.16

Recently, the two leading flexible organic light-emitting diode (OLED) display manufacturers, Samsung and LG, were reported to introduce atomic layer deposition (ALD) technology in the barrier film manufacturing process.

Currently, both Samsung and LG use alternating organic/inorganic layers to protect the OLED devices, which are extremely sensitive to oxygen and moisture (for more details, see the report “The Multi-Billion-Dollar Emerging Display Opportunities”).

However, the way they encapsulate OLED devices are different. Samsung deposits barrier films directly on to OLED devices in the fabrication process – organic layers via vacuum evaporation and inorganic layers via sputtering, a technology acquired from Vitex in 2011. LG, on the other hand, manufactures the barrier films separately on foil substrates and then laminates the films onto OLED devices. LG is already using ALD to deposit the inorganic layers, based on a Veeco’s FAST-ALD technology.

Whether the rumor is true or not, Samsung and LG’s choice may not be the answer to all OLED barrier problems. To select a good barrier film technology, three key factors need to be considered: the encapsulation approach, the barrier layer structure, and deposition method.

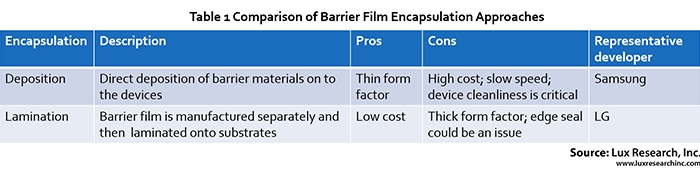

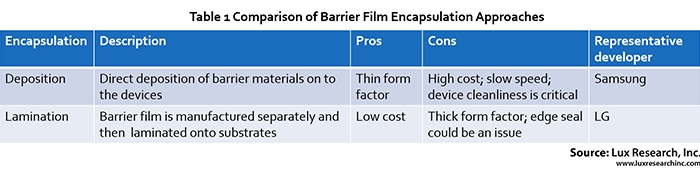

• Encapsulation approach refers to how the barrier film is applied to the OLED device. Deposition and lamination are the two dominant methods. In-line deposition typically has a thin form factor, but corresponds to high cost and slow throughput. Lamination, on the other hand, is low in cost but requires very good lamination adhesives:

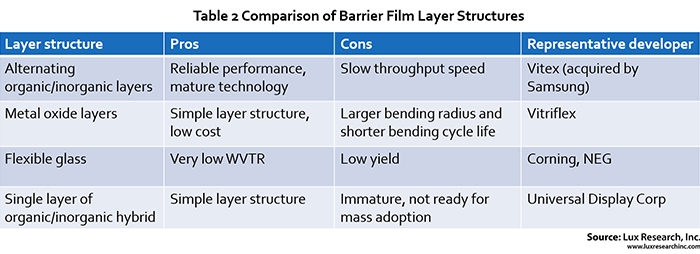

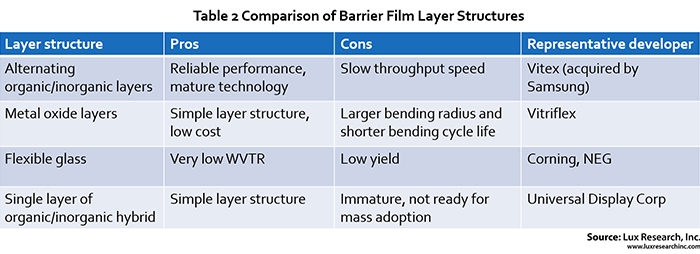

• Layer structure refers to layer number and core material. While incumbent technologies are based on alternating organic/inorganic layers, there are emerging designs of the layer structure. For example, Vitriflex develops an all-metal-oxide barrier film that has three layers. Corning plans to use flexible glass for encapsulation, and UDC develops a single-layer barrier with a hybrid organic/inorganic material. A detailed comparison of the four structures can be seen in the table below:

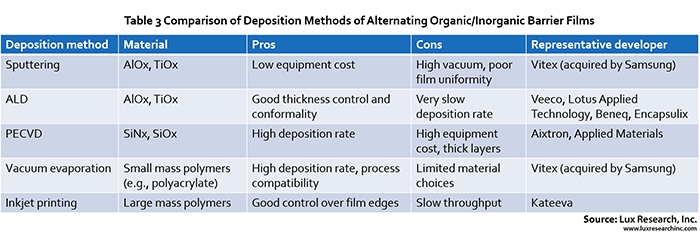

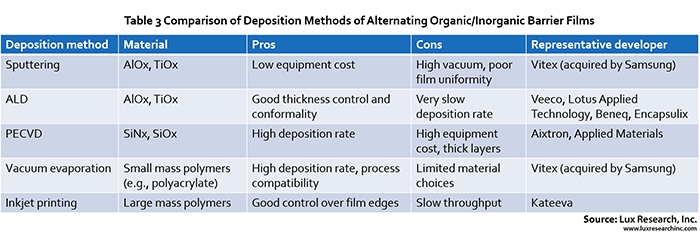

• Deposition method refers to how each layer of barrier film materials is processed. For example, manufacturing of alternating organic/inorganic barriers needs two different sets of deposition methods, one for the inorganic layers (sputtering, ALD, PECVD), and another one for organic layers (vacuum evaporation, inkjet printing; see the table below). As for other layer structures, Vitriflex’s metal-oxide film uses sputtering, flexible glass is made by slot die coating.

Since most of today’s barrier film developers are able to achieve a water vapor transmission rate (WVTR) of 10-6 g/m2/day, there is no clear winner in meeting the basic barrier requirements of flexible OLEDs. Thus, picking an appropriate technology is dependent on specific OLED device needs for applications in scalability, cost and film quality. For example, in-line deposition is typically good for small substrates, while lamination is better in large area applications. Sputtering is good for simple OLED devices with flat surfaces, and ALD is better in more complex pixel structures due to better device conformity. Vacuum evaporation might be good for organic layers in most applications, but inkjet printing has a better position for displays with unconventional shapes and edges.

As a result, because each combination of the encapsulation approach, the barrier film structure, and deposition methods is unique in offering different processing advantages, different types of barrier film technologies will continue to co-exist and eventually find their ways into different applications. Those interested should continue to monitor the space closely and pick partners depending on their own needs and capabilities.

Tony Sun, Ph.D., leads the Electronic User Inter Intelligence team at Lux Research. Lux Research provides strategic advice and on-going intelligence for emerging technologies.

Currently, both Samsung and LG use alternating organic/inorganic layers to protect the OLED devices, which are extremely sensitive to oxygen and moisture (for more details, see the report “The Multi-Billion-Dollar Emerging Display Opportunities”).

However, the way they encapsulate OLED devices are different. Samsung deposits barrier films directly on to OLED devices in the fabrication process – organic layers via vacuum evaporation and inorganic layers via sputtering, a technology acquired from Vitex in 2011. LG, on the other hand, manufactures the barrier films separately on foil substrates and then laminates the films onto OLED devices. LG is already using ALD to deposit the inorganic layers, based on a Veeco’s FAST-ALD technology.

Whether the rumor is true or not, Samsung and LG’s choice may not be the answer to all OLED barrier problems. To select a good barrier film technology, three key factors need to be considered: the encapsulation approach, the barrier layer structure, and deposition method.

• Encapsulation approach refers to how the barrier film is applied to the OLED device. Deposition and lamination are the two dominant methods. In-line deposition typically has a thin form factor, but corresponds to high cost and slow throughput. Lamination, on the other hand, is low in cost but requires very good lamination adhesives:

• Layer structure refers to layer number and core material. While incumbent technologies are based on alternating organic/inorganic layers, there are emerging designs of the layer structure. For example, Vitriflex develops an all-metal-oxide barrier film that has three layers. Corning plans to use flexible glass for encapsulation, and UDC develops a single-layer barrier with a hybrid organic/inorganic material. A detailed comparison of the four structures can be seen in the table below:

• Deposition method refers to how each layer of barrier film materials is processed. For example, manufacturing of alternating organic/inorganic barriers needs two different sets of deposition methods, one for the inorganic layers (sputtering, ALD, PECVD), and another one for organic layers (vacuum evaporation, inkjet printing; see the table below). As for other layer structures, Vitriflex’s metal-oxide film uses sputtering, flexible glass is made by slot die coating.

Since most of today’s barrier film developers are able to achieve a water vapor transmission rate (WVTR) of 10-6 g/m2/day, there is no clear winner in meeting the basic barrier requirements of flexible OLEDs. Thus, picking an appropriate technology is dependent on specific OLED device needs for applications in scalability, cost and film quality. For example, in-line deposition is typically good for small substrates, while lamination is better in large area applications. Sputtering is good for simple OLED devices with flat surfaces, and ALD is better in more complex pixel structures due to better device conformity. Vacuum evaporation might be good for organic layers in most applications, but inkjet printing has a better position for displays with unconventional shapes and edges.

As a result, because each combination of the encapsulation approach, the barrier film structure, and deposition methods is unique in offering different processing advantages, different types of barrier film technologies will continue to co-exist and eventually find their ways into different applications. Those interested should continue to monitor the space closely and pick partners depending on their own needs and capabilities.

Tony Sun, Ph.D., leads the Electronic User Inter Intelligence team at Lux Research. Lux Research provides strategic advice and on-going intelligence for emerging technologies.