10.09.19

TactoTek announced that at K 2019 Arburg it will feature a live production demonstration of injection molded structural electronics (IMSE) parts (Hall 13, Stand A 13).

K 2019 takes place Oct. 16-23 in Düsseldorf, Germany.

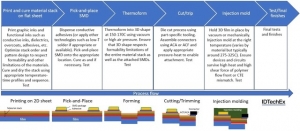

TactoTek’s proprietary IMSE technology integrates printed electronics and electronic components within 3D injection molded structures to create thin, seamless, electronically active and economical smart molded structures.

The company licenses IMSE technology to manufacturers who design and mass produce parts for their customers.

The IMSE part being produced at K 2019 is a design that includes in-mold circuitry, touch controls and LEDs for lighting, all of which are encapsulated in polycarbonate resin in an advanced film insert molding (FIM) process. The finished part is 3.5 mm thick and weighs only 49 grams. TactoTek technology partner content includes DuPont conductive ink and Cypress touch controllers. Several thousand IMSE parts will be produced during the event.

The automated IMSE manufacturing demonstration is built around Arburg’s electric Allrounder 470A injection molding machine and includes an FPT multi-axis robot, Kiki gripper and centering station, Motan material dryer, Dr. Eschrich film cleaning station, MFP conveyor for molded parts and tray server for film supply, Söhner trays and a Regloplast temperature control unit.

K 2019 takes place Oct. 16-23 in Düsseldorf, Germany.

TactoTek’s proprietary IMSE technology integrates printed electronics and electronic components within 3D injection molded structures to create thin, seamless, electronically active and economical smart molded structures.

The company licenses IMSE technology to manufacturers who design and mass produce parts for their customers.

The IMSE part being produced at K 2019 is a design that includes in-mold circuitry, touch controls and LEDs for lighting, all of which are encapsulated in polycarbonate resin in an advanced film insert molding (FIM) process. The finished part is 3.5 mm thick and weighs only 49 grams. TactoTek technology partner content includes DuPont conductive ink and Cypress touch controllers. Several thousand IMSE parts will be produced during the event.

The automated IMSE manufacturing demonstration is built around Arburg’s electric Allrounder 470A injection molding machine and includes an FPT multi-axis robot, Kiki gripper and centering station, Motan material dryer, Dr. Eschrich film cleaning station, MFP conveyor for molded parts and tray server for film supply, Söhner trays and a Regloplast temperature control unit.