09.10.21

Checkpoint Systems has announced a new move into the pharmaceutical sector by joining the DoseID Consortium.

The self-governing, US-based consortium established to unify the industry around an approach to serialized RFID-tagged pharmaceutical products aims to ensure the quality, performance, and interoperability of RFID-tagged products as they move through the supply chain.

The new Spiro Plus M750 label, developed by engineers at Checkpoint and DoseID certified, can be applied to pharmaceutical products at the point of manufacture, enabling them to be tracked throughout the supply chain. The RFID-enabled inventory management solution helps hospitals modernize restocking processes and automate them to save redundant drug spend and ensure patient safety.

This will effectively enable hospital pharmacies to better manage their inventory, as well as provide compounders and pharmaceutical manufacturers with accurate data on ‘beyond use’ expiration, medication compounding history, and recalls.

The new Spiro Plus M750 has been developed exclusively for the challenging environments in which RFID-tagged products will be scanned. It delivers excellent performance in a range of scenarios, including in the presence of RF-inhibiting factors like liquids, metals, and high tag density.

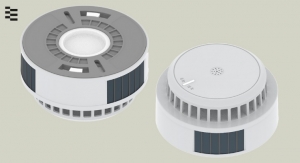

The Spiro Plus M750 design. (Source: Checkpoint Systems)

Utilizing the Impinj Monza M750 IC, the label has also achieved ARC’s Spec S Certification, further demonstrating its excellent performance and detection rates. This certification means that pharma manufacturers can use this inlay on their DoseID Certified drugs. A 26 x 14mm in size can be applied to a wide variety of products.

“The environments in the pharmaceutical sector make it extremely challenging for RFID to perform well,” Craig Weakley, director of applications development at Checkpoint Systems, said. “There is no margin of error and the inlay needs to be developed specifically for the application – there really is no off-the-shelf solution. We are delighted with the accuracy and performance of the Spiro Plus label, which combines the collective and unique experience of our teams at Checkpoint and CCL Healthcare.

“Quality and standards have always been pivotal to the pharmaceutical sector, but the whole industry has been put in the spotlight over the last year due to the pandemic. Solutions that help it quickly and accurately identify fluid-filled containers in densely-packed environments will be hugely important with increased demands on medicines over the coming years.”

Despite being a relative newcomer to the pharmaceutical sector, Checkpoint has built a wealth of RF and RFID-based experience in numerous other industries, particularly retail where it has supported businesses for more than 50 years.

As part of CCL Industries, the world’s largest converter of pressure sensitive and specialty extruded film materials for a wide range of applications used by government institutions and large global customers in the consumer packaging, healthcare & chemicals, consumer electronic device, and automotive markets, Checkpoint has become one the leading global manufacturers of RFID inlays, as well as a developer of high-performance software and hardware.

The self-governing, US-based consortium established to unify the industry around an approach to serialized RFID-tagged pharmaceutical products aims to ensure the quality, performance, and interoperability of RFID-tagged products as they move through the supply chain.

The new Spiro Plus M750 label, developed by engineers at Checkpoint and DoseID certified, can be applied to pharmaceutical products at the point of manufacture, enabling them to be tracked throughout the supply chain. The RFID-enabled inventory management solution helps hospitals modernize restocking processes and automate them to save redundant drug spend and ensure patient safety.

This will effectively enable hospital pharmacies to better manage their inventory, as well as provide compounders and pharmaceutical manufacturers with accurate data on ‘beyond use’ expiration, medication compounding history, and recalls.

The new Spiro Plus M750 has been developed exclusively for the challenging environments in which RFID-tagged products will be scanned. It delivers excellent performance in a range of scenarios, including in the presence of RF-inhibiting factors like liquids, metals, and high tag density.

The Spiro Plus M750 design. (Source: Checkpoint Systems)

“The environments in the pharmaceutical sector make it extremely challenging for RFID to perform well,” Craig Weakley, director of applications development at Checkpoint Systems, said. “There is no margin of error and the inlay needs to be developed specifically for the application – there really is no off-the-shelf solution. We are delighted with the accuracy and performance of the Spiro Plus label, which combines the collective and unique experience of our teams at Checkpoint and CCL Healthcare.

“Quality and standards have always been pivotal to the pharmaceutical sector, but the whole industry has been put in the spotlight over the last year due to the pandemic. Solutions that help it quickly and accurately identify fluid-filled containers in densely-packed environments will be hugely important with increased demands on medicines over the coming years.”

Despite being a relative newcomer to the pharmaceutical sector, Checkpoint has built a wealth of RF and RFID-based experience in numerous other industries, particularly retail where it has supported businesses for more than 50 years.

As part of CCL Industries, the world’s largest converter of pressure sensitive and specialty extruded film materials for a wide range of applications used by government institutions and large global customers in the consumer packaging, healthcare & chemicals, consumer electronic device, and automotive markets, Checkpoint has become one the leading global manufacturers of RFID inlays, as well as a developer of high-performance software and hardware.