Low weight, no need for cables and highly automated manufacturing of fully customized components: Printed electronics offers many advantages for the aviation industry.

At the LOPEC Conference 2019, Dennis Hahn from aircraft manufacturer Airbus and Max Seissler from the consulting and technology company Altran will provide an overview of the special requirements placed on flying components. Based in Hamburg, Germany, they are cooperating on printed electronics for the aircraft cabin. In this interview, they illustrate the challenges and visions.

Since when has the aviation industry been interested in printed electronics?

Dennis Hahn: As early as 20 years ago, university researchers recognized that printed electronics is of interest for the construction of aircraft and presented their results to Airbus. At that time, however, the materials did not yet meet the extremely high safety requirements of aviation. But a lot has happened since then. Together with two Fraunhofer Institutes and Altran, we have developed demonstrators, and together with Altran, we are currently providing proof that printed electronics are ready for applications in aviation.

Dennis Hahn: As early as 20 years ago, university researchers recognized that printed electronics is of interest for the construction of aircraft and presented their results to Airbus. At that time, however, the materials did not yet meet the extremely high safety requirements of aviation. But a lot has happened since then. Together with two Fraunhofer Institutes and Altran, we have developed demonstrators, and together with Altran, we are currently providing proof that printed electronics are ready for applications in aviation.

What are the specific requirements that the materials have to meet?

Hahn: We examine flammability, for example. To do this, the films on which we print the electronics are held over an open flame for 15 seconds. They are then removed and must extinguish themselves within 14 seconds if they caught fire—a tough test for plastics. Even our fire experts cannot predict how a combination of film, ink and coating is going to behave. That is why we had to test various materials.

Max Seissler: We have tried from the outset to minimize risks and use materials that are already aviation-certified. But when we use these materials for other applications and in new combinations, additional tests are required. And flammability is just one issue. The components must be resistant to moisture and condensation, aggressive cleaning agents, insecticides, extreme temperatures, vibration and more.

You are cooperating on innovations for the aircraft cabin. What are the advantages of printed electronics in this field?

Seissler: At the beginning of the project two years ago, we initially had an optimized production in mind. Airlines want the furnishings of their aircraft to be customized. Corporate branding should be reflected in the cabin. For aircraft manufacturers, however, it is expensive if one customer wants a display here and the next one wants something else there because for conventional electronics cables have to be planned and laid. This is still often done manually and takes weeks. If we print the conductor paths on film, we can eliminate cables. Our goal is a digitized, automated production: a modular printing line, right next to the production line, that allows the implementation of individual requirements within a few hours to days, even if the customer makes a decision at the last minute.

Hahn: With printed electronics, we can realize new system architectural concepts. We assemble the customized electronic components and integrate them into the cabin module without having to modify the aircraft's hardware. This enables us to offer our customers even more options for customized furnishings. And at the same time, printed electronics help us to reduce weight.

Seissler: Moreover, we need less space if we install flat film instead of cables for the transmission of power or data—and there are thousands of them hidden behind the paneling in the aircraft. If we save this space, the cabin will be larger, and the passengers will have a much more pleasant flight experience.

What stage has your printed electronics project reached?

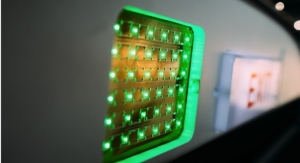

Hahn: We are now working on the first near-series prototypes, on a display module for the emergency exit and for the toilets in the cabin. We screen print a silver ink onto a polymer carrier, which we then glue onto a honeycomb structure.

Do you only print with silver or do you also use organic inks?

Seissler: We use silver inks for the info panel. For other prototypes, for instance in sensor technology, we are also working with organic inks. There is an extremely large number of possible applications for sensors in aviation. Sensors integrated into the outer skin, for example, can measure loads and provide information on when the aircraft requires the next overhaul or repair cycle. Temperature and humidity sensors, on the other hand, can be used for climate monitoring. Printed electronics in aircraft construction is an extremely broad field, from organic light-emitting diodes for cabin lighting to RFID antennas in manufacturing, that enable the tracking of when certain components are ready for installation at which specific production site.

Seissler: We use silver inks for the info panel. For other prototypes, for instance in sensor technology, we are also working with organic inks. There is an extremely large number of possible applications for sensors in aviation. Sensors integrated into the outer skin, for example, can measure loads and provide information on when the aircraft requires the next overhaul or repair cycle. Temperature and humidity sensors, on the other hand, can be used for climate monitoring. Printed electronics in aircraft construction is an extremely broad field, from organic light-emitting diodes for cabin lighting to RFID antennas in manufacturing, that enable the tracking of when certain components are ready for installation at which specific production site.

What comes after the printed info panel? Do you have any long-term visions?

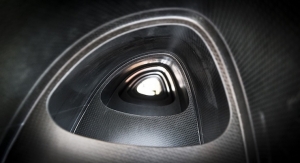

Hahn: Airbus not only builds passenger aircraft but also develops ideas for the urban transport of the future. Take the future concept “Pop-Up”: This is about air taxis for cities, flight attachments for autonomous automobiles, and the combination of car and drone. This is what tomorrow's mobility looks like—and printed electronics should make it all possible.

Seissler: As the flying cars are electrically powered, weight reduction comes even more into play. Every kilogram plays a decisive role here.

At the LOPEC Conference, you will give a plenary lecture. What topics are you going to cover?

Hahn: We want to talk about the requirements of the aviation industry in general, but also about our current developments and about where we are headed. It should become clear that, in the future, printed electronics will enable the realization of bold ideas.

Seissler: Moreover, there are still some outstanding issues, for instance with regard to connectors. Numerous functions and applications can already be printed on film. However, the films must ultimately be connected to a power or data network. We are still looking for compelling solutions that meet the strict requirements of aviation.

Hahn: It is generally the case that we deal with cutting-edge technologies in aircraft construction. Many companies are in a kind of awe of these high requirements. This is probably one of the reasons why there is currently still a gap between what we need in aviation and what is on offer.

Seissler: We have been attending LOPEC for several years, this time we will be actively represented for the first time with a lecture. We would like to seize this opportunity and call on all potential partners to support us.

The plenary lecture “Applications for printed electronics in the aviation industry” will take place during the LOPEC Conference 2019 on March 21 at 9:25 a.m. at the International Congress Center Munich in room 14b. In addition, a demonstrator for aircraft interior paneling will be on display at the Innovation Showcase (B0 318).