David Savastano, Editor08.30.17

One of the most important advantages of additive manufacturing is its ability to produce prototypes much faster than older methods. What used to take weeks and months now can be done in a matter of days or even hours.

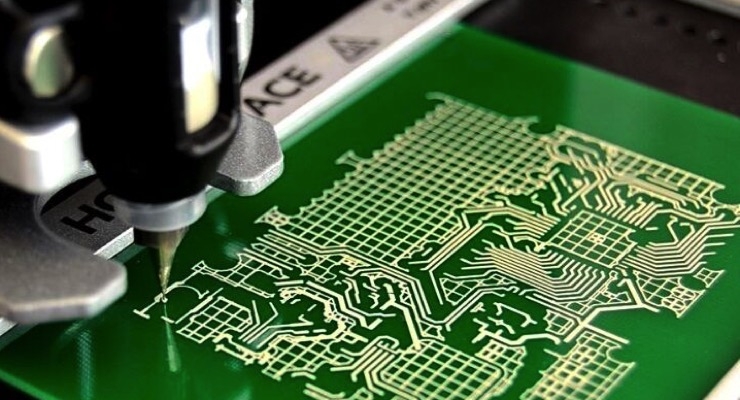

Voltera Inc. is successfully developing desktop printing solutions for PCBs. The winner of the CPES2017 Commercialization Award from the Canadian Printable Electronics Industry Association (CPEIA), Voltera Inc.’s Voltera V-One dispenses solder paste, conductive ink and reflowing components, dramatically reducing prototyping time for PCBs to days or even hours.

“With more than 500 units shipped to 50 countries, Voltera is already beginning to revolutionize the circuit board prototyping business for sectors ranging from automotive to telecom and consumer electronics,” said Peter Kallai, CPEIA’s executive director, said in presen ting the CPES2017 award. “There are only a few companies in this space in the world.”

Achieving this success took a lot of hard work. Alroy Almeida, CEO and co-founder of Voltera Inc., noted that the Kitchener, Ontario-based company worked for more than two years to develop the technology that would become the V-One, and still is improving it.

“We started Voltera in 2013 and spent the first two years developing the technology that would evolve into the V-One,” said Almeida. “It was publicly launched in winter 2015 and we've been working with our customers to continuously improve the system since then.”

Almeida said that the driving force behind Voltera is the concept of accessibility.

“The V-One itself is incredibly easy to use with magnetically attachable printheads, the software has videos that guide you through every step of the print process, and we offer a wide variety of blank substrates and dev kit templates to help get projects off the ground even faster,” he reported. “While accessibility drives all user experience discussions we have, performance drives the product discussions. To ensure we set the benchmark for desktop PCB printers, we spent extensive time and R&D to offer the best solderability, conductivity and reliability.”

Today, Almeida noted that V-Ones are being used in more than 50 countries around the world in dozens of industries including medical devices, robotics, automotive, robotics and IoT.

“These businesses have been able to accelerate their time to market or to deliver prototypes to clients faster,” he added. “We’re also exceptionally proud of the adoption by the academic space, where the V-One is regularly used as a research tool and a teaching tool in secondary and post-secondary education.”

Almeida said that Voltera is utilizing what it is learning about printed electronics to branch into new fields.

“Voltera exists with one foot in the printed electronics space, and the other foot in manufacturing,” said Almeida. “When we look ahead, we see ourselves continuing to leverage the science and processes from the PE space to solve unique challenges in the broader electronics industry. We'll have our first add-on to the V-One platform releasing later this year, which will be a standard-of-life improvement in the creation of double-sided boards, and are working with customers to test ideas for future products as well.”

Receiving the CPEIA Commercialization Award is paryicularly meaningful for Almeida and his team.

“The PE space is starting to grow at a rapid rate, so to be selected for the Commercialization Award among a growing group of fantastic companies was truly humbling,” he said. “When we first began this company, we spoke to the experts from this industry and they informed us that the path ahead would be incredibly difficult, if not impossible, and so this award feels like a catharsis that makes all the long nights and rough times worth it.”

Almeida sees excellent opportunities ahead for Voltera and flexible and printed electronics.

“As key applications like smart packaging and wearables come closer to broader adoption of flex and PE, we're we're excited about the role the Voltera V-One can play since businesses need a proving ground before adopting a new technology. We're on the verge of traditional FR4 PCBs being viewed as one of several options flavors of electronics,” he concluded.

Voltera Inc. is successfully developing desktop printing solutions for PCBs. The winner of the CPES2017 Commercialization Award from the Canadian Printable Electronics Industry Association (CPEIA), Voltera Inc.’s Voltera V-One dispenses solder paste, conductive ink and reflowing components, dramatically reducing prototyping time for PCBs to days or even hours.

“With more than 500 units shipped to 50 countries, Voltera is already beginning to revolutionize the circuit board prototyping business for sectors ranging from automotive to telecom and consumer electronics,” said Peter Kallai, CPEIA’s executive director, said in presen ting the CPES2017 award. “There are only a few companies in this space in the world.”

Achieving this success took a lot of hard work. Alroy Almeida, CEO and co-founder of Voltera Inc., noted that the Kitchener, Ontario-based company worked for more than two years to develop the technology that would become the V-One, and still is improving it.

“We started Voltera in 2013 and spent the first two years developing the technology that would evolve into the V-One,” said Almeida. “It was publicly launched in winter 2015 and we've been working with our customers to continuously improve the system since then.”

Almeida said that the driving force behind Voltera is the concept of accessibility.

“The V-One itself is incredibly easy to use with magnetically attachable printheads, the software has videos that guide you through every step of the print process, and we offer a wide variety of blank substrates and dev kit templates to help get projects off the ground even faster,” he reported. “While accessibility drives all user experience discussions we have, performance drives the product discussions. To ensure we set the benchmark for desktop PCB printers, we spent extensive time and R&D to offer the best solderability, conductivity and reliability.”

Today, Almeida noted that V-Ones are being used in more than 50 countries around the world in dozens of industries including medical devices, robotics, automotive, robotics and IoT.

“These businesses have been able to accelerate their time to market or to deliver prototypes to clients faster,” he added. “We’re also exceptionally proud of the adoption by the academic space, where the V-One is regularly used as a research tool and a teaching tool in secondary and post-secondary education.”

Almeida said that Voltera is utilizing what it is learning about printed electronics to branch into new fields.

“Voltera exists with one foot in the printed electronics space, and the other foot in manufacturing,” said Almeida. “When we look ahead, we see ourselves continuing to leverage the science and processes from the PE space to solve unique challenges in the broader electronics industry. We'll have our first add-on to the V-One platform releasing later this year, which will be a standard-of-life improvement in the creation of double-sided boards, and are working with customers to test ideas for future products as well.”

Receiving the CPEIA Commercialization Award is paryicularly meaningful for Almeida and his team.

“The PE space is starting to grow at a rapid rate, so to be selected for the Commercialization Award among a growing group of fantastic companies was truly humbling,” he said. “When we first began this company, we spoke to the experts from this industry and they informed us that the path ahead would be incredibly difficult, if not impossible, and so this award feels like a catharsis that makes all the long nights and rough times worth it.”

Almeida sees excellent opportunities ahead for Voltera and flexible and printed electronics.

“As key applications like smart packaging and wearables come closer to broader adoption of flex and PE, we're we're excited about the role the Voltera V-One can play since businesses need a proving ground before adopting a new technology. We're on the verge of traditional FR4 PCBs being viewed as one of several options flavors of electronics,” he concluded.