David Savastano, Editor11.21.18

IDTechEx LIVE! 2018 and Printed Electronics USA 2018, organized by IDTechEx, concluded its two-day conference and trade show at the Santa Clara Convention Center, Santa Clara, CA, highlighting new technologies and applications from areas as diverse as sensors, wearables, smart packaging and more.

The conference featured eight concurrent sessions: Printed Electronics, Sensors, Wearables, Internet of Things (IoT) Applications, 3D Printing, Electric Vehicles, Energy Storage Innovations, Graphene and 2D Materials. Leaders throughout the field, from major brand owners to innovative start-ups, showed how flexible and printed electronics can play a major role in everyday life.

IDTechEx CEO Raghu Das said the show had approximately 3,500 attendees from 42 countries, with 284 exhibiting organizations.

“It has grown strongly versus the previous year,” Das said. “A key aspect is that the full range of applications and technologies of printed electronics are covered at the event, and how, due to the nature of the diverse range of industries attending, organizations could meet with and explore opportunities of printed electronics in many different vertical segments.”

“It feels way bigger than before,” said IDTechEx director Dr. Jon Harrop. “It seems the diversification works out really well. We pull in relevant people in a wide range of fields, bringing people together in the same place.”

IDTechEx LIVE! Day 2 Conference Highlights

IDTechEx Live!’s presenters offered a wide-ranging look at new technologies, from photovoltaics and wearables for health monitoring to smart packaging, manufacturing and foldable smartphones.

Dr. Brian Worfolk, director of organic photovoltaics, Phillips 66, discussed “Phillips 66 Organic Photovoltaics,” a look at the company’s efforts in the OPV space.

“OPVs offer a differentiated value proposition, including flexibility and the use of different colors.,” Dr. Worfork said. “We have been working on OPV for many years, reaching 12.14% efficiency, and have 40 active patents/applications.”

Dr. Linh Le, founder and CEO at Bonbouton, discussed diabetes care in his talk on “Wearable Graphene Platform for Digital Health Applications.”

“Diabetes has a devastating global effect,” said Dr. Le. “Five-year mortality after the first foot amputation is 60%. Monitoring reduces the risk of foot ulcers.”

Dr. Le noted that Bonbouton is developing its Bonbouton Foot Health Monitoring system and app.

“We can detect changes in foot temperature and pressure,” Dr. Le noted. “We deploy a flexible sensor in the insole that is inkjet printed with graphene. We are working with WL Gore, the maker of Gore-Tex, and with Liquid X to collaborate on creating advanced textile-based sensors. In the future, clothes will act as the natural physical interface of the body to measure vital signs.”

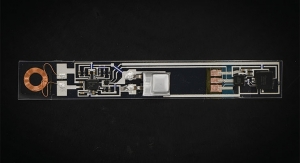

Dr. Davor Sutija, CEO at Thin Film Electronics, discussed the use of NFC by brand owners in his talk on “From Stand-Alone Memory to Printed Systems.”

“Most of the connections occur outside of the store,” Dr. Sutija reported. “People are becoming digitally native. Their smartphone is becoming an aid in deciding what to buy. Once you start serializing NFC, you have a unique way of identifying every consumer interaction. This is a way for brands to talk with consumers.”

In his talk on “Making Money at the Edge,” Geoff Mulligan CTO for IIoT at Jabil, spoke about the proliferation of sensors in everyday life, and how these sensors an improve life.

“We make lots of things, but profit margins are low,” Mulligan noted. “We have to add value for our customers, and the IoT is driving lots of things. How can we attach sensors to items, do condition monitoring, like monitoring a refrigerator so you know when it is going to break down and it can be fixed before that? What about shared benefits like energy management and predictive maintenance?”

Royole Corporation made headlines recently when it announced FlexPai, the world’s first commercially available foldable smartphone. Dr. Ze Yuan, R&D director-Flexible Display Business Group at Royole, talked about the company’s experiences in his presentation on “Mass Manufacturing of Flexible OLED Displays.”

Dr. Yuan noted that Royole was founded in 2012 out of Stanford University, and has more than 2,000 patents.

“We work on flexible sensors, flexible displays and other solutions,” Dr. Yuan said. “Our fab is in 24/7 mode. We are actually making flexible displays into products, which have been tested over 200,000 times for bending, so there are no more broken screens.”

Dr. Yuan said that the FlexPai foldable smartphone, which has a 7.8” display when opened, is the product of tremendous efforts.

“It takes a lot of work to create this for the consumer level,” he said. “There are more than 1,100 patents on this. It will take time for developers to build up the ecosystem. This is a first generation device, but it is fun to see the technology become more consumer ready. We are ready to start selling it. We are also working on a rollable keyboard and a flexible auto dashboard. It is a very exciting age.”

Exhibitors’ Thoughts

Overall, exhibitors said the exhibition went well, with attendees being focused on how technology can be used on their specific projects.

“What impressed me was the number of end users at the show and their familiarity with their needs so they could make decisions at the show,” Dr. Dan Harrision, EVP at IIMAK, said. “That was different than previous years.”

Dr. Dene Taylor, president of SPF-Inc., highlighted Metallograph along with Dr. Harrison of IIMAK.

“We had a lot of traffic at the booth, and the two of us were busy nearly all the time,” Dr. Tayor said. “ Visitors were nearly all industrial, which is our target, and also predominantly executives and managers. We provide production solutions, and got some interests that should lead to placement of the Gerber industrial printer, and others into prototyping and design.”

“Our impression is that it is a bit less than last year, but we had the same number of leads and the second day was better than years past. People are also more interested in products,” said Thomas Kolbusch, VP for Coatema Coatings Machinery GmbH.

Tim Luong, national sales manager for CERADROP, an MGI Group company, noted that Ceradrop-MGI demonstrated a live equipment demo that was state-of-the-art integrated non-contact deposition and curing steps solution for printing electronics and numerous applications area of sensors developments.

He added that the wildfires may have led to reduced attendee traffic.

“The people that visit Ceradrop are focused on collaborations with Ceradrop global teams seeking inkjet, aerosol jet, and multi-curing solutions,” Luong added.

Roy Bjorlin, commercial and strategic initiatives director, Printed Electronics for Sun Chemical, said that new technologies keep emerging.

“I was excited by some of the innovations, and it was great to see what’s new in wearables. We continue to see innovations in sensors and in-mold technologies,” Bjorlin added.

Nick Schmidt, business development at Frontier, A Delta ModTech Company, said that foot traffic was good. “It’s been a good learning experience,” Schmidt said. “We had a lot of good leads, and there were a lot of new faces here.”

“It has been a very good show for us leadwise as well as working with existing customers,” said Don Veri, sales and business development with Meyer Burger.

“IDTechEx is a good fit for us to meet customers as our technology crosses over for visitors and exhibitors alike,” Richard Ellinger, VP sales and marketing for American Semiconductor, said. “Our booth was busy throughout the event and we have made some excellent progress by meeting key future business partners.”

“The presentations in the technical sessions continued last year’s trend of improvement,” Doug Hackler, American Semiconductor president, added. “It is great to see progress across our segment for IoT, smart packaging and hybrid manufacturing.”

XENON Corporation highlighted its X1100 benchtop Pulsed Light system at the show. “The X1100 is designed for the labs, and offers limitless flexibility,” said XENON CEO Lou Panico. “It seems like the best show we’ve been at. People are very interested in our technology.”

Elise Silagy, marketing & events manager for NovaCentrix, said that NovCentrix highlighted its new capabilities, including the PulseForge Invent photonic curing tool, which now is being used for photonic soldering.

“We were consistently talking with people who had very relevant interest, customers and potential new customers alike,” Silagy added. “We are working overtime to keep up with orders.”

Attendees take in the talks during Printed Electronics USA 2018.

The conference featured eight concurrent sessions: Printed Electronics, Sensors, Wearables, Internet of Things (IoT) Applications, 3D Printing, Electric Vehicles, Energy Storage Innovations, Graphene and 2D Materials. Leaders throughout the field, from major brand owners to innovative start-ups, showed how flexible and printed electronics can play a major role in everyday life.

IDTechEx CEO Raghu Das said the show had approximately 3,500 attendees from 42 countries, with 284 exhibiting organizations.

“It has grown strongly versus the previous year,” Das said. “A key aspect is that the full range of applications and technologies of printed electronics are covered at the event, and how, due to the nature of the diverse range of industries attending, organizations could meet with and explore opportunities of printed electronics in many different vertical segments.”

“It feels way bigger than before,” said IDTechEx director Dr. Jon Harrop. “It seems the diversification works out really well. We pull in relevant people in a wide range of fields, bringing people together in the same place.”

IDTechEx LIVE! Day 2 Conference Highlights

IDTechEx Live!’s presenters offered a wide-ranging look at new technologies, from photovoltaics and wearables for health monitoring to smart packaging, manufacturing and foldable smartphones.

Dr. Brian Worfolk, director of organic photovoltaics, Phillips 66, discussed “Phillips 66 Organic Photovoltaics,” a look at the company’s efforts in the OPV space.

“OPVs offer a differentiated value proposition, including flexibility and the use of different colors.,” Dr. Worfork said. “We have been working on OPV for many years, reaching 12.14% efficiency, and have 40 active patents/applications.”

Dr. Linh Le, founder and CEO at Bonbouton, discussed diabetes care in his talk on “Wearable Graphene Platform for Digital Health Applications.”

“Diabetes has a devastating global effect,” said Dr. Le. “Five-year mortality after the first foot amputation is 60%. Monitoring reduces the risk of foot ulcers.”

Dr. Le noted that Bonbouton is developing its Bonbouton Foot Health Monitoring system and app.

“We can detect changes in foot temperature and pressure,” Dr. Le noted. “We deploy a flexible sensor in the insole that is inkjet printed with graphene. We are working with WL Gore, the maker of Gore-Tex, and with Liquid X to collaborate on creating advanced textile-based sensors. In the future, clothes will act as the natural physical interface of the body to measure vital signs.”

Dr. Davor Sutija, CEO at Thin Film Electronics, discussed the use of NFC by brand owners in his talk on “From Stand-Alone Memory to Printed Systems.”

“Most of the connections occur outside of the store,” Dr. Sutija reported. “People are becoming digitally native. Their smartphone is becoming an aid in deciding what to buy. Once you start serializing NFC, you have a unique way of identifying every consumer interaction. This is a way for brands to talk with consumers.”

In his talk on “Making Money at the Edge,” Geoff Mulligan CTO for IIoT at Jabil, spoke about the proliferation of sensors in everyday life, and how these sensors an improve life.

“We make lots of things, but profit margins are low,” Mulligan noted. “We have to add value for our customers, and the IoT is driving lots of things. How can we attach sensors to items, do condition monitoring, like monitoring a refrigerator so you know when it is going to break down and it can be fixed before that? What about shared benefits like energy management and predictive maintenance?”

Royole Corporation made headlines recently when it announced FlexPai, the world’s first commercially available foldable smartphone. Dr. Ze Yuan, R&D director-Flexible Display Business Group at Royole, talked about the company’s experiences in his presentation on “Mass Manufacturing of Flexible OLED Displays.”

Dr. Yuan noted that Royole was founded in 2012 out of Stanford University, and has more than 2,000 patents.

“We work on flexible sensors, flexible displays and other solutions,” Dr. Yuan said. “Our fab is in 24/7 mode. We are actually making flexible displays into products, which have been tested over 200,000 times for bending, so there are no more broken screens.”

Dr. Yuan said that the FlexPai foldable smartphone, which has a 7.8” display when opened, is the product of tremendous efforts.

“It takes a lot of work to create this for the consumer level,” he said. “There are more than 1,100 patents on this. It will take time for developers to build up the ecosystem. This is a first generation device, but it is fun to see the technology become more consumer ready. We are ready to start selling it. We are also working on a rollable keyboard and a flexible auto dashboard. It is a very exciting age.”

Exhibitors’ Thoughts

Overall, exhibitors said the exhibition went well, with attendees being focused on how technology can be used on their specific projects.

“What impressed me was the number of end users at the show and their familiarity with their needs so they could make decisions at the show,” Dr. Dan Harrision, EVP at IIMAK, said. “That was different than previous years.”

Dr. Dene Taylor, president of SPF-Inc., highlighted Metallograph along with Dr. Harrison of IIMAK.

“We had a lot of traffic at the booth, and the two of us were busy nearly all the time,” Dr. Tayor said. “ Visitors were nearly all industrial, which is our target, and also predominantly executives and managers. We provide production solutions, and got some interests that should lead to placement of the Gerber industrial printer, and others into prototyping and design.”

“Our impression is that it is a bit less than last year, but we had the same number of leads and the second day was better than years past. People are also more interested in products,” said Thomas Kolbusch, VP for Coatema Coatings Machinery GmbH.

Tim Luong, national sales manager for CERADROP, an MGI Group company, noted that Ceradrop-MGI demonstrated a live equipment demo that was state-of-the-art integrated non-contact deposition and curing steps solution for printing electronics and numerous applications area of sensors developments.

He added that the wildfires may have led to reduced attendee traffic.

“The people that visit Ceradrop are focused on collaborations with Ceradrop global teams seeking inkjet, aerosol jet, and multi-curing solutions,” Luong added.

Roy Bjorlin, commercial and strategic initiatives director, Printed Electronics for Sun Chemical, said that new technologies keep emerging.

“I was excited by some of the innovations, and it was great to see what’s new in wearables. We continue to see innovations in sensors and in-mold technologies,” Bjorlin added.

Nick Schmidt, business development at Frontier, A Delta ModTech Company, said that foot traffic was good. “It’s been a good learning experience,” Schmidt said. “We had a lot of good leads, and there were a lot of new faces here.”

“It has been a very good show for us leadwise as well as working with existing customers,” said Don Veri, sales and business development with Meyer Burger.

“IDTechEx is a good fit for us to meet customers as our technology crosses over for visitors and exhibitors alike,” Richard Ellinger, VP sales and marketing for American Semiconductor, said. “Our booth was busy throughout the event and we have made some excellent progress by meeting key future business partners.”

“The presentations in the technical sessions continued last year’s trend of improvement,” Doug Hackler, American Semiconductor president, added. “It is great to see progress across our segment for IoT, smart packaging and hybrid manufacturing.”

XENON Corporation highlighted its X1100 benchtop Pulsed Light system at the show. “The X1100 is designed for the labs, and offers limitless flexibility,” said XENON CEO Lou Panico. “It seems like the best show we’ve been at. People are very interested in our technology.”

Elise Silagy, marketing & events manager for NovaCentrix, said that NovCentrix highlighted its new capabilities, including the PulseForge Invent photonic curing tool, which now is being used for photonic soldering.

“We were consistently talking with people who had very relevant interest, customers and potential new customers alike,” Silagy added. “We are working overtime to keep up with orders.”

Attendees take in the talks during Printed Electronics USA 2018.