David Savastano, Editor02.10.21

Twenty years ago, the idea of flexible hybrid and printed electronics (FHE) was but a figment in the imagination of researchers. However, the idea of flexible displays, such as organic light-emitting displays (OLEDs), was of interest for military and commercial applications.

With that in mind, the US Display Consortium (USDC) decided it was time to host their first conference in 2001. The USDC created the Flexible Microelectronics Manufacturing Workshop; looking at the agenda from the following year, much of the workshop centered on the technical challenges centered on flexible displays.

Much has changed over the years. The USDC would morph into FlexTech Alliance, which is now a strategic partner of SEMI. Today, the Flexible Microelectronics Manufacturing Workshop is now known as FLEX, and is celebrating its 20th anniversary. The audience has grown steadily, from 60 in the first year to nearly 650 registrants, depending on the year, location and other factors.

While OLEDs remain a technology of interest, FHEs are the key focus, as flexible sensors and wearables are finding homes in major markets such as automotive, healthcare and much more.

The History of FLEX

FLEX was created in 2001 as the Flexible Microelectronics Manufacturing Workshop by CTO Bob Pinnel. Mike Ciesinski, president of FlexTech Alliance, a SEMI Strategic Association Partner, said that the workshop was designed to bring together the best thinkers on the state-of-the-art in displays, materials, processing and related technologies and determine a roadmap of technology gaps for developing for manufacturing of flexible displays.

“This type of work was not being done anywhere else,” Ciesinski said. “The main driver for USDC in flexible display manufacturing was the US Army Research Laboratory (ARL), who wanted to (and still does want to) outfit soldiers with more portable and rugged electronics.”

USDC and ARL had been funding projects in the field for several years and realized the flexible display technology needed completely new paradigms in manufacturing - whether roll-to-roll was possible, rather than sheet-based – and new materials, such as flexible barrier layers for moisture-sensitive OLEDs.

Heidi Hoffman, senior director, marketing and communications for SEMI, added, “As more and more researchers learned of the event and the challenges it was created to highlight, the topics have expanded to include multiple materials and process sessions, applications sessions, interconnect and equipment. The session list from each year is very illuminating on the progress and thinking of the industry experts.”

Looking at the first few years of the conference, the early emphasis was on how to get to a conformable display. Hoffman said that quickly transitioned to manufacturing on flexible substrates, and concepts for flexible batteries, human performance monitors, wearables, smart materials, and more.

“Since it was always a technical conference first, we had trouble calling it a ‘show’, but eventually so many companies wanted to show their products as well as talk about their products, we added a 12 table, tabletop exhibition around 2004,” she added. “That eventually grew to host more than 60 exhibitors.

“Exhibitors realized that the attendees of the conference were the buyers and influencers who knew the technology so well that they are buyers, but also key contributors to products’ further development,” Hoffman continued. “The exhibit floor quickly became more of a place for building collaborations and many exhibitors return year-after-year for this reason. That dynamic has also lent itself to the event being a very collegial environment overall.”

Joining SEMI

In October 2015, SEMI announced that FlexTech Alliance became its first Strategic Association Partner. This provided FlexTech Alliance with a global platform. Ciesinski said the merger foretells changes in two directions.

“First, from the SEMI vantage point, the microelectronics supply chain is more than traditional materials and equipment supplies into fabs,” Ciesinski said. “And by bringing in FlexTech as the first strategic alliance, the packaging, interconnect and non-Si elements of the semiconductor industry began to be folded into the SEMI reach helping to emphasize the importance of post-fab technology.

“From the FlexTech vantage point, technology adoption is slow if it does not get into the hands of the users that can make the most of it. New technology introduction can be accelerated by tapping into the SEMI constituency. This is a win/win for the customer that gets leading-edge products and the industry that supplies into and manufactures that product,” Ciesinski added.

The Evolution into FHE

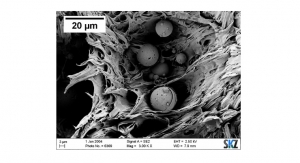

While the USDC was originally looking into flexible organic displays, other associations were focusing on printed electronics. The problem was that the fully printed electronics are not a mainstream technology for a variety of reasons. Combining traditional silicon-based electronics with flexible substrates, possibly using printing, led to FHE and a host of new opportunities.

Melissa Grupen-Shemansky, CTO of SEMI, said that in the last 20 years, the world has seen some of the most dramatic changes in the semiconductor industry since the invention of the solid state device.

“The outsourcing or fabless craze of the early 2000s changed the way the industry looks at manufacturing,” Grupen-Shemansky observed. “This led to greater and greater off-shoring of semiconductor manufacturing from the US and a greater concentration of manufacturing skill in Asia.

“Then there is Moore’s Law,” Grupen-Shemansky added. “Well before the 14nm node, top fabs in the world like TSMC started emphasizing the importance of advance packaging like flip chip and 3D as well as OSATs taking up additional multichip packaging and new interconnect technologies like FOWLP. Advance off-chip interconnect trend and importance has increased as node shrinks hit 14nm and below where fab costs skyrocketed and linear shrinks were hitting practical limits.”

These dynamic shifts have opened the doors and the industry’s investments to multi-chip solutions, heterogeneous integration, and advance board assembly where the board or subsystem becomes the package. This is where FHE sits.

“But FHE brings more to the party,” Grupen-Shemansky said. “It enables conformal electronics not limited to box-shaped and in some cases soft or stretchable. FHE also employs what is called additive processing, which, in comparison to substrative processing often used in semiconductors, has the promise of being faster, more customizable and more ecologically friendly. These promising features led to the MII, NextFlex, to develop pilot manufacturing process and design platforms.

“Also, R&D on possible applications solutions was born, such as NBMC, which concentrates on integration R&D, bringing the building blocks of FHE technology together to develop wearable electronic sensing systems to enable both commercial and military markets. The health and medical wearable market is likely to be the largest growth market for FHE,” Grupen-Shemansky noted.

The Future of FLEX

Looking back at early USDC programs through this year’s agenda, it is telling that many committed leaders give much of their time to growing the conference and the industry.

“Industry has been a key partner and this event has always been industry-driven. We have harnessed the interests and directions of our international program committees to identify and invite speakers who are at the leading edge or innovation,” Hoffman said.

The Program Committees have led the contents for the programs, short courses, student posters and more. What started as a workshop to identify technology development for flexible display quickly transformed into sessions on all of the inputs needed to successfully develop flexible products, from their displays to the boards, to the chips, sensors and power supplies,” she added.

“Our Board of Directors and other experts saw flexible electronics as just a part of an emerging flexible electronics industry,” Ciesinski said. “Many visionaries have contributed over the years, including Chris Ober of Cornell, Dalen Keys of DuPont, Diego Olego of Philips, Dan Gamota of Motorola (now with Jabil), Mike McCreary of E Ink, and envisioned a future of electronics being manufactured on substrates other than hard and brittle, e.g., silicon wafers, display glass. Roll-to-roll manufacturing was envisioned, as were applications in many spaces - telecom, medical, aerospace, retail, etc.”

FLEX 2021 is different than previous conferences, as it will be held virtually due to the COVID-19 pandemic. However, what does not change is the emphasis on the latest technological advances. FHEs and the FLEX conference alike have lots to bring to attendees in the coming years.

“The FLEX show is an industry event where innovation is showcased and the customers and suppliers get a front-row seat, early in the development process,” Hoffman concluded.