David Savastano, Editor06.23.21

Sustainability is a topic of increasing interest in the field of flexible and printed electron-ics, and industry leaders report they are hearing questions about sustainability from their customers. One of these topics is recyclability and reusability.

“The focus is on making PE or FHE devices compatible with existing recycling processes because the end-of-life scenario is mainly defined by the application context,” VITO researcher Kévin Le Blevennec, a team member with the OE-A sustainability group, said. “PE materials are being developed with a minimal ecologic footprint as a major development goal.”

Dr. Gerardo Hernandez-Sosa, group leader Printed Electronics Group at InnovationLab, noted that for many of the plastic substrates in use, there are existing recycling procedures.

“For example, PET, which is used in plastic bottles, is a commonly used substrate which post treatment is well established. In addition, there is a big industry around printing electronics on paper. Furthermore, there are research efforts to fabricate electronics on other biodegradable substrates,” added Dr. Hernandez-Sosa.

There is work being done on creating flexible electronics products that can be recycled or reused, but Wolfgang Mildner of msw tech noted that more needs to be done.

“My impression is that we need to do more,” said Mildner. “A clear concept which sepa-rates disposable and reusable parts for instance for patches is needed because of hygienic reasons but also due to sustainability”.

For example, Imprint Energy’s flexible batteries can be recharged, which makes this a more sustainable solution.

“Our solution partners want a sustainable power source,” Imprint Energy CEO Christine Ho said. “Our solid state battery, with a polymer-based electrolyte, gives them a greener solution with an extended life. You can make the battery smaller knowing you can cycle it multiple times.”

Dr. Gity Samadi, SEMI FlexTech program manager, said that within SEMI FlexTech, sus-tainability was one of four topics for project funding.

“We expect that emphasis to remain through future Requests for Proposals (RFPs),” said Dr. Samadi. “One proposed approach was to consider multi-use products-rather than sin-gle-use disposables. For example, developing an electronic label which can be used multi-ple times rather than just once.”

Rob Frueh, senior business development manager for Brewer Science, said that Brewer Science smart devices and printed electronics program currently has several key focuses on recycling and reusability.

“One of those is the goal that our products not become consumables,” Frueh said. “This brings the attention in certain applications on making our sensors not only recyclable or reusable, but also plug and play. Having the ability to rapidly exchange a component or sensor means a reduction not only in the total amount of waste, but in potential downtime, service contracts, and overall ownership costs.”

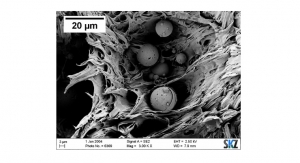

Heliatek GmbH is a leader in organic photovoltaics, a key opportunity for sustainability. Stephan Kube, Heliatek’s head of marketing, said that end-of-life treatment is still being evaluated.

“With only using very small material amounts, there are no scarce or highly valuable materials in it, a recycling process that is economically and ecologically reasonable is the chal-lenge,”Kube said. “So, at the end it might be that incineration could be the most eco-friendly way at the end-of-life, because you even generate electricity by burning. Some recycling process are quite resource and energy consuming, so it might not be as eco-friendly as it looks like. Re-use of our products is rather complicated, as we have a compound product with different thin material layers which are firmly connected to each other.”

“The focus is on making PE or FHE devices compatible with existing recycling processes because the end-of-life scenario is mainly defined by the application context,” VITO researcher Kévin Le Blevennec, a team member with the OE-A sustainability group, said. “PE materials are being developed with a minimal ecologic footprint as a major development goal.”

Dr. Gerardo Hernandez-Sosa, group leader Printed Electronics Group at InnovationLab, noted that for many of the plastic substrates in use, there are existing recycling procedures.

“For example, PET, which is used in plastic bottles, is a commonly used substrate which post treatment is well established. In addition, there is a big industry around printing electronics on paper. Furthermore, there are research efforts to fabricate electronics on other biodegradable substrates,” added Dr. Hernandez-Sosa.

There is work being done on creating flexible electronics products that can be recycled or reused, but Wolfgang Mildner of msw tech noted that more needs to be done.

“My impression is that we need to do more,” said Mildner. “A clear concept which sepa-rates disposable and reusable parts for instance for patches is needed because of hygienic reasons but also due to sustainability”.

For example, Imprint Energy’s flexible batteries can be recharged, which makes this a more sustainable solution.

“Our solution partners want a sustainable power source,” Imprint Energy CEO Christine Ho said. “Our solid state battery, with a polymer-based electrolyte, gives them a greener solution with an extended life. You can make the battery smaller knowing you can cycle it multiple times.”

Dr. Gity Samadi, SEMI FlexTech program manager, said that within SEMI FlexTech, sus-tainability was one of four topics for project funding.

“We expect that emphasis to remain through future Requests for Proposals (RFPs),” said Dr. Samadi. “One proposed approach was to consider multi-use products-rather than sin-gle-use disposables. For example, developing an electronic label which can be used multi-ple times rather than just once.”

Rob Frueh, senior business development manager for Brewer Science, said that Brewer Science smart devices and printed electronics program currently has several key focuses on recycling and reusability.

“One of those is the goal that our products not become consumables,” Frueh said. “This brings the attention in certain applications on making our sensors not only recyclable or reusable, but also plug and play. Having the ability to rapidly exchange a component or sensor means a reduction not only in the total amount of waste, but in potential downtime, service contracts, and overall ownership costs.”

Heliatek GmbH is a leader in organic photovoltaics, a key opportunity for sustainability. Stephan Kube, Heliatek’s head of marketing, said that end-of-life treatment is still being evaluated.

“With only using very small material amounts, there are no scarce or highly valuable materials in it, a recycling process that is economically and ecologically reasonable is the chal-lenge,”Kube said. “So, at the end it might be that incineration could be the most eco-friendly way at the end-of-life, because you even generate electricity by burning. Some recycling process are quite resource and energy consuming, so it might not be as eco-friendly as it looks like. Re-use of our products is rather complicated, as we have a compound product with different thin material layers which are firmly connected to each other.”