David Savastano, Editor11.10.17

The field of flexible and printed electronics is generating more interest in numerous markets, with sensors being one of the most prominent early successes. These sensors are appearing in markets ranging from medical, airplanes and automobiles to packaging and cosmetics, to name a few.

“I would say there’s tremendous growth in both the number and diversity of applications for sensors – there are many applications in monitoring all sorts of things,” said Malcolm Thompson, executive director of NextFlex, America’s Flexible Hybrid Electronics Institute. “We’re all familiar with the athletic and medical monitors that are being developed, but it goes way beyond that. There are structural monitors, sensors for measuring stress in pipes, dams and airplane wings, all the way through to agricultural sensors. These devices can measure the amount of water in soil, as well as monitor chemicals around plants to determine contamination or assess when they’re ready to be harvested.

“The sheer diversity of sensor applications is staggering,” Thompson added. “They must be inexpensive so they can be produced in large numbers, and they’re designed to be consumable – they essentially biodegrade, and then you start again, which makes for a great business model. Basically, the potential applications for sensors are practically limitless.”

With approximately $31 billion in sales in 2016, L’Oréal is one of the five largest beauty businesses in the world. Through the L’Oréal’s Technology Incubator and its R&D teams, L’Oreal is always creating new products for the beauty market, including My UV Patch, a stretchable skin sensor that monitors UV absorption. In conjunction with La Roche-Posay, L’Oreal’s skin care brand, and MC10 Inc., L’Oreal created the My UVPatch.

Since the heart-shaped patch’s introduction in January 2016, the company reports that more than one million patches have been sold, led by consumers from the US, France, Russia, Australia and Chile.

“My team, L’Oréal’s Technology Incubator, developed My UV Patch, along with wearable technology company MC10, whose expertise in heath and biomedical adhesives informed the sensor’s ultrathin, stretchable adhesive,” said Guive Balooch, global VP of L’Oréal’s Technology Incubator. “L’Oréal skincare brand La Roche-Posay provides the patch for free with purchase of their sunscreen. My UV Patch unites innovative technology with L’Oréal’s extensive scientific research on skin and La Roche-Posay’s mission to increase consumers’ sun-safe behaviors.”

Being aware of the impact of sunlight on the skin is becoming increasing important. A patch is a good way to monitor the skin, but the key is to make it unobtrusive. Balooch said that L’Oreal did just that.

“We needed to create a wearable that wouldn’t interfere with the user’s daily routine – it had to be very comfortable, flexible and thin,” Balooch said. “Most wearables are accessories that you take off and on and some can’t be used for all activities. The challenge was to create a sensor that’s like a second skin, but also highly effective and accurate.”

Dr. Robert Smith, technical fellow and NextFlex Fellow, Boeing Research & Technology, said that Boeing Research and Technology has identified a number of application spaces that would benefit from sensors that are integrated with flexible and printed electronics.

“Boeing Research and Technology is focusing on the use of flexible sensors for factory operations, add-on sensors for enhanced data collection services and advanced health monitoring for products. From an engineering perspective, there is always interest in acquiring more data from platforms in operation or during test,” Dr. Smith added. “A constraint to collecting data is the distributed nature of gathering sensor data today, which requires access at physical locations; wiring for data, power and control; and large integration tasks to connect all the required assets that collect and process the data.

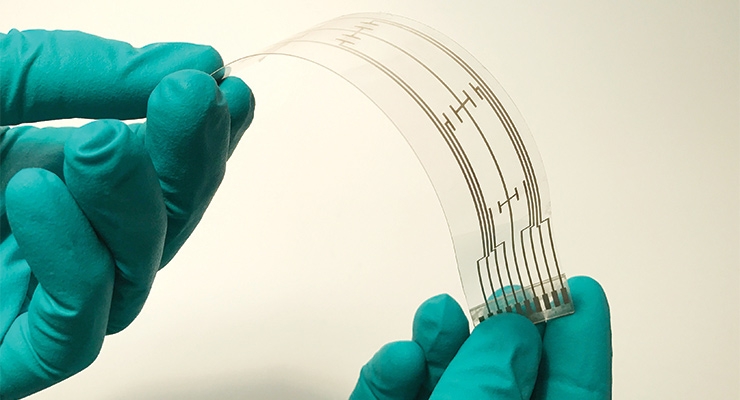

“With the emergence of flexible hybrid electronics, the possibility of integrating power, communication, processing and sensor capability onto a single flexible, conformal device becomes realizable,” Dr. Smith continued. “The constraint to achieving this realization is the availability of the types of sensors that can be produced by printed methods. Boeing Research and Technology sees this as a large growth area with a lot of untapped potential for new sensing architectures for data collection in new modalities and in size, weight and power efficient structures.”

“We see tremendous growth opportunities for flexible and printed sensors and Brewer Science is continuing to make substantial investments in our printed electronics and devices programs,” said Dominic Miranda, regional account manager for Brewer Science.

Stan Farnsworth, VP of marketing for NovaCentrix, said that he has seen a lot of recent growth, specifically in the medical sensor application space.

“A number of companies have come to us to either understand how these technologies can be applied to improve their current sensor offerings, or to work with us in applying our conductive inks and photonic curing tools for new sensors,” Farnsworth noted. “Other application areas like automotive and aerospace are also increasingly developing more extensive sensor applications for improved product functionality, a richer user experience, and also in conjunction with big-data analytical trends. For these applications, broader sensor implementation allows everything from more efficient design and operation at a micro product/user level up to macro-level intelligent fleet management, regional placement of spares and repair centers, and even predictive maintenance savings.”

Roy Bjorlin, global commercial and strategic initiatives director, Electronics Materials, Sun Chemical, observed that the interest in producing sensors has increased dramatically.

“The fundamentals of flexible printed electronics and the associated performance requirements are suited to driving new advancements in sensor design, including wearables both for the consumer and medical applications,” Bjorlin noted. “However, those same attributes, including formability, moldability and being stretchable, also lend the development of these advanced material sets to a wider range of applications which would benefit from printed solutions.”

“We have been producing medical sensors for years, but the number of applications is increasing at a steady pace,” added Tom Bianchi, VP of Eastprint Incorporated.

“BeBop Sensors has spent years qualifying and selecting the best inks for each sensor application; producing cheap, reliable, and resilient fabric sensors is not possible without flexible printed circuitry,” said Keith McMillen, president of BeBop Sensors. “After 40 years of incremental progress, the field of flexible and printed electronics is in a renaissance of growth, pushed in large part by an expansion in the possibilities of flexible, stretchable fabric sensors.”

“We are optimistic about the flexible sensor market, but the commercialization roadmap is unclear due to the large number of start-ups working in this space,” said Jaye Tyler, president of Si-Cal Technologies (A Nissha Company). “Wearable sensors for active wear could be more challenging due to design cycles related to fashion trends – a garment-agnostic thermal transfer circuit approach may be best for this segment. In general, we are very positive on printed sensors.”

Interesting Projects

There are many intriguing products in the market and many more coming. Dr. Smith said that Boeing Research and Technology has utilized FHE approaches to fabricate miniature flexible passive tracking tags for use on non-metallic and small items to aid in detection and localization of such items during production and maintenance operations.

“FHE design and manufacturing approaches enabled this tracking method that could not be achieved by other methods,” Dr. Smith added. “The prototype system using these FHE tags is currently being evaluated.”

“It’s impossible to choose only one,” said Miranda. “All of the projects in which we are engaged are interesting, and they all share a commonality. Printed electronics give us a tremendous amount of customizability, which allows us to provide our customer with a solution unique to their needs. Printing also allows us to quickly engineer changes in design to improve form and function. We have delivered changes in a custom solution from design to prototype to manufacturability over a matter of a few weeks.

“Brewer Science’s InFlect line of sensors include flexible thermistors, moisture and bend sensors that are fast, lightweight, low-power solutions,” said Miranda. “These flexible sensors can conform to irregular surfaces which enable sensing in areas previously not possible with conventional rigid sensors. Brewer Science is currently working on new air (gas/VOC) and water (pH/ion conductivity) for environmental monitoring.”

“We’ve been excited to have the opportunity to support the work of Dr. Ana Arias and her group at UC Berkeley,” said Farnsworth. “They have been developing a printed flexible EMG electrode for improved data monitoring compared with traditional electrodes. One of the technical challenges the effort has faced, which is consistent with challenges seen in the FHE space in general, is how to seamlessly combine flexible printed electronics technologies with traditional SMT and connector technologies. We are working together to pioneer some new methods.

“Another interesting project is with InkSpace Imaging, a spin-out from Dr. Arias’ lab at UC Berkeley,” Farnsworth added. “This project is also extremely interesting because Dr. Arias and her team have identified that current MRI RF coils used during clinical exams are woefully unfriendly to the kids. Current MRI vests coil arrays are designed for one-size-fits-all adults.

We all know adults do not come in one size, and the standard-issue MRI coil arrays are especially mismatched for pediatric use from both a comfort perspective and also an accuracy perspective. Dr. Arias and her team are using the production capabilities of printed and flexible electronics to fashion quick-turn-around size-specific coil arrays for children. Their pediatric coil arrays is packaged in friendly looking fabric and designed as vests for newborns and small blankets for children ages 2-6. These individualized vests might result in a less-traumatic experience for already-anxious kids (and their families) and also in improved diagnostic accuracy due to more conformal fit. Plus, they might also help fix real-world discomfort and improve diagnostic inaccuracy for those among us that are not one-size-fits-all grown-ups.”

“We are heavily involved in in-mold electronics (IME) and medical wearable patch assemblies,” said Bianchi. “Sadly, confidentiality agreements preclude us from discussing the applications.”

“BeBop’s Data Glove is a synthesis of the latest advancements in printed electronics: a lightweight, flexible, one-size-fits-all glove that accurately maps the human hand in real time,” said McMillen. “By deploying its core fabric sensing technology to measure bend, stretch, and pressure, BeBop has produced a Data Glove that completely maps the complex motions of a human hand. No other company has integrated bend sensors at each knuckle, abduction sensors between each finger, and an IMU (Inertial Measurement Unit) into a low-cost, machine washable, highly durable glove package.”

“Since our acquisition of Gwent Electronic Materials, we have been exposed to a number of interesting medical and bio sensor applications,” said Bjorlin. “We are working collaboratively with a number of companies on new designs in patient care, patient monitoring and sensors for diagnostics.

“Our R&D teams are working diligently to produce enhancements in conductive inks, including a range of advanced polymer thick film (PTF) silver, gold and platinum inks, nanomaterials, and next generation metalations,” Bjorlin added. “The latter is part of our collaboration with GGI Solutions and the National Research Council of Canada (NRC), which is focused on a new inks system based on a range of molecular silver and copper inks. These new materials offer advantages in cost, fine line capability and smooth high attenuation surfaces. Combined with our nano silver portfolio we believe we can open doors in next generation sensor applications.”

“Medical monitoring is one area that is really exploding,” concluded Thompson. “Just a few examples that have been developed include wireless EKG technology; wound monitoring, which accelerates recovery through automated oxygenation of wounds; biofluidic monitoring; and hydration monitoring for enhanced athletic performance. Again, the applications seem almost limitless in terms of the number of different types of monitors that can be implemented. The technology is in place, so it’s more a matter of determining the business model – we need to get the price right and position the device properly so that it’s ready to manufacture in large quantities.”

“The market is highly diverse,” Thompson continued. “There will be a point in the near future where these sensors will have become part of our everyday lives in almost every imaginable aspect. One of the things that intrigues me is wondering what, in five years’ time, we will be talking about in terms of, ‘I wouldn’t have thought we could have done that.’"

“I would say there’s tremendous growth in both the number and diversity of applications for sensors – there are many applications in monitoring all sorts of things,” said Malcolm Thompson, executive director of NextFlex, America’s Flexible Hybrid Electronics Institute. “We’re all familiar with the athletic and medical monitors that are being developed, but it goes way beyond that. There are structural monitors, sensors for measuring stress in pipes, dams and airplane wings, all the way through to agricultural sensors. These devices can measure the amount of water in soil, as well as monitor chemicals around plants to determine contamination or assess when they’re ready to be harvested.

“The sheer diversity of sensor applications is staggering,” Thompson added. “They must be inexpensive so they can be produced in large numbers, and they’re designed to be consumable – they essentially biodegrade, and then you start again, which makes for a great business model. Basically, the potential applications for sensors are practically limitless.”

With approximately $31 billion in sales in 2016, L’Oréal is one of the five largest beauty businesses in the world. Through the L’Oréal’s Technology Incubator and its R&D teams, L’Oreal is always creating new products for the beauty market, including My UV Patch, a stretchable skin sensor that monitors UV absorption. In conjunction with La Roche-Posay, L’Oreal’s skin care brand, and MC10 Inc., L’Oreal created the My UVPatch.

Since the heart-shaped patch’s introduction in January 2016, the company reports that more than one million patches have been sold, led by consumers from the US, France, Russia, Australia and Chile.

“My team, L’Oréal’s Technology Incubator, developed My UV Patch, along with wearable technology company MC10, whose expertise in heath and biomedical adhesives informed the sensor’s ultrathin, stretchable adhesive,” said Guive Balooch, global VP of L’Oréal’s Technology Incubator. “L’Oréal skincare brand La Roche-Posay provides the patch for free with purchase of their sunscreen. My UV Patch unites innovative technology with L’Oréal’s extensive scientific research on skin and La Roche-Posay’s mission to increase consumers’ sun-safe behaviors.”

Being aware of the impact of sunlight on the skin is becoming increasing important. A patch is a good way to monitor the skin, but the key is to make it unobtrusive. Balooch said that L’Oreal did just that.

“We needed to create a wearable that wouldn’t interfere with the user’s daily routine – it had to be very comfortable, flexible and thin,” Balooch said. “Most wearables are accessories that you take off and on and some can’t be used for all activities. The challenge was to create a sensor that’s like a second skin, but also highly effective and accurate.”

Dr. Robert Smith, technical fellow and NextFlex Fellow, Boeing Research & Technology, said that Boeing Research and Technology has identified a number of application spaces that would benefit from sensors that are integrated with flexible and printed electronics.

“Boeing Research and Technology is focusing on the use of flexible sensors for factory operations, add-on sensors for enhanced data collection services and advanced health monitoring for products. From an engineering perspective, there is always interest in acquiring more data from platforms in operation or during test,” Dr. Smith added. “A constraint to collecting data is the distributed nature of gathering sensor data today, which requires access at physical locations; wiring for data, power and control; and large integration tasks to connect all the required assets that collect and process the data.

“With the emergence of flexible hybrid electronics, the possibility of integrating power, communication, processing and sensor capability onto a single flexible, conformal device becomes realizable,” Dr. Smith continued. “The constraint to achieving this realization is the availability of the types of sensors that can be produced by printed methods. Boeing Research and Technology sees this as a large growth area with a lot of untapped potential for new sensing architectures for data collection in new modalities and in size, weight and power efficient structures.”

“We see tremendous growth opportunities for flexible and printed sensors and Brewer Science is continuing to make substantial investments in our printed electronics and devices programs,” said Dominic Miranda, regional account manager for Brewer Science.

Stan Farnsworth, VP of marketing for NovaCentrix, said that he has seen a lot of recent growth, specifically in the medical sensor application space.

“A number of companies have come to us to either understand how these technologies can be applied to improve their current sensor offerings, or to work with us in applying our conductive inks and photonic curing tools for new sensors,” Farnsworth noted. “Other application areas like automotive and aerospace are also increasingly developing more extensive sensor applications for improved product functionality, a richer user experience, and also in conjunction with big-data analytical trends. For these applications, broader sensor implementation allows everything from more efficient design and operation at a micro product/user level up to macro-level intelligent fleet management, regional placement of spares and repair centers, and even predictive maintenance savings.”

Roy Bjorlin, global commercial and strategic initiatives director, Electronics Materials, Sun Chemical, observed that the interest in producing sensors has increased dramatically.

“The fundamentals of flexible printed electronics and the associated performance requirements are suited to driving new advancements in sensor design, including wearables both for the consumer and medical applications,” Bjorlin noted. “However, those same attributes, including formability, moldability and being stretchable, also lend the development of these advanced material sets to a wider range of applications which would benefit from printed solutions.”

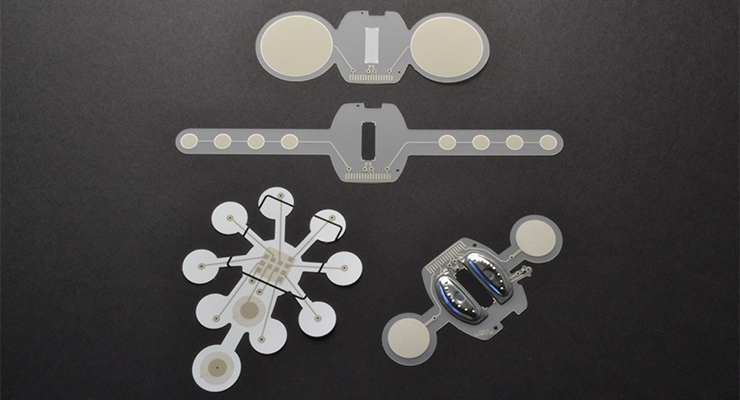

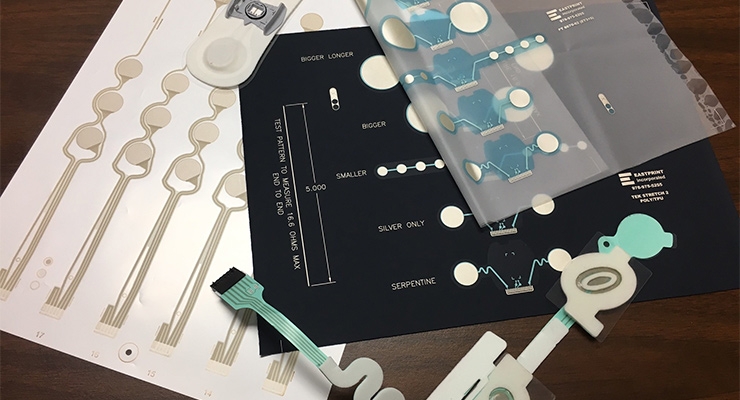

“We have been producing medical sensors for years, but the number of applications is increasing at a steady pace,” added Tom Bianchi, VP of Eastprint Incorporated.

“BeBop Sensors has spent years qualifying and selecting the best inks for each sensor application; producing cheap, reliable, and resilient fabric sensors is not possible without flexible printed circuitry,” said Keith McMillen, president of BeBop Sensors. “After 40 years of incremental progress, the field of flexible and printed electronics is in a renaissance of growth, pushed in large part by an expansion in the possibilities of flexible, stretchable fabric sensors.”

“We are optimistic about the flexible sensor market, but the commercialization roadmap is unclear due to the large number of start-ups working in this space,” said Jaye Tyler, president of Si-Cal Technologies (A Nissha Company). “Wearable sensors for active wear could be more challenging due to design cycles related to fashion trends – a garment-agnostic thermal transfer circuit approach may be best for this segment. In general, we are very positive on printed sensors.”

Interesting Projects

There are many intriguing products in the market and many more coming. Dr. Smith said that Boeing Research and Technology has utilized FHE approaches to fabricate miniature flexible passive tracking tags for use on non-metallic and small items to aid in detection and localization of such items during production and maintenance operations.

“FHE design and manufacturing approaches enabled this tracking method that could not be achieved by other methods,” Dr. Smith added. “The prototype system using these FHE tags is currently being evaluated.”

“It’s impossible to choose only one,” said Miranda. “All of the projects in which we are engaged are interesting, and they all share a commonality. Printed electronics give us a tremendous amount of customizability, which allows us to provide our customer with a solution unique to their needs. Printing also allows us to quickly engineer changes in design to improve form and function. We have delivered changes in a custom solution from design to prototype to manufacturability over a matter of a few weeks.

“Brewer Science’s InFlect line of sensors include flexible thermistors, moisture and bend sensors that are fast, lightweight, low-power solutions,” said Miranda. “These flexible sensors can conform to irregular surfaces which enable sensing in areas previously not possible with conventional rigid sensors. Brewer Science is currently working on new air (gas/VOC) and water (pH/ion conductivity) for environmental monitoring.”

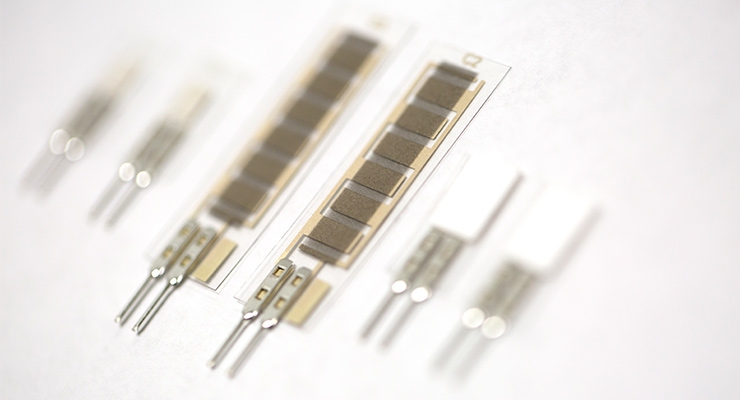

“We’ve been excited to have the opportunity to support the work of Dr. Ana Arias and her group at UC Berkeley,” said Farnsworth. “They have been developing a printed flexible EMG electrode for improved data monitoring compared with traditional electrodes. One of the technical challenges the effort has faced, which is consistent with challenges seen in the FHE space in general, is how to seamlessly combine flexible printed electronics technologies with traditional SMT and connector technologies. We are working together to pioneer some new methods.

“Another interesting project is with InkSpace Imaging, a spin-out from Dr. Arias’ lab at UC Berkeley,” Farnsworth added. “This project is also extremely interesting because Dr. Arias and her team have identified that current MRI RF coils used during clinical exams are woefully unfriendly to the kids. Current MRI vests coil arrays are designed for one-size-fits-all adults.

We all know adults do not come in one size, and the standard-issue MRI coil arrays are especially mismatched for pediatric use from both a comfort perspective and also an accuracy perspective. Dr. Arias and her team are using the production capabilities of printed and flexible electronics to fashion quick-turn-around size-specific coil arrays for children. Their pediatric coil arrays is packaged in friendly looking fabric and designed as vests for newborns and small blankets for children ages 2-6. These individualized vests might result in a less-traumatic experience for already-anxious kids (and their families) and also in improved diagnostic accuracy due to more conformal fit. Plus, they might also help fix real-world discomfort and improve diagnostic inaccuracy for those among us that are not one-size-fits-all grown-ups.”

“We are heavily involved in in-mold electronics (IME) and medical wearable patch assemblies,” said Bianchi. “Sadly, confidentiality agreements preclude us from discussing the applications.”

“BeBop’s Data Glove is a synthesis of the latest advancements in printed electronics: a lightweight, flexible, one-size-fits-all glove that accurately maps the human hand in real time,” said McMillen. “By deploying its core fabric sensing technology to measure bend, stretch, and pressure, BeBop has produced a Data Glove that completely maps the complex motions of a human hand. No other company has integrated bend sensors at each knuckle, abduction sensors between each finger, and an IMU (Inertial Measurement Unit) into a low-cost, machine washable, highly durable glove package.”

“Since our acquisition of Gwent Electronic Materials, we have been exposed to a number of interesting medical and bio sensor applications,” said Bjorlin. “We are working collaboratively with a number of companies on new designs in patient care, patient monitoring and sensors for diagnostics.

“Our R&D teams are working diligently to produce enhancements in conductive inks, including a range of advanced polymer thick film (PTF) silver, gold and platinum inks, nanomaterials, and next generation metalations,” Bjorlin added. “The latter is part of our collaboration with GGI Solutions and the National Research Council of Canada (NRC), which is focused on a new inks system based on a range of molecular silver and copper inks. These new materials offer advantages in cost, fine line capability and smooth high attenuation surfaces. Combined with our nano silver portfolio we believe we can open doors in next generation sensor applications.”

“Medical monitoring is one area that is really exploding,” concluded Thompson. “Just a few examples that have been developed include wireless EKG technology; wound monitoring, which accelerates recovery through automated oxygenation of wounds; biofluidic monitoring; and hydration monitoring for enhanced athletic performance. Again, the applications seem almost limitless in terms of the number of different types of monitors that can be implemented. The technology is in place, so it’s more a matter of determining the business model – we need to get the price right and position the device properly so that it’s ready to manufacture in large quantities.”

“The market is highly diverse,” Thompson continued. “There will be a point in the near future where these sensors will have become part of our everyday lives in almost every imaginable aspect. One of the things that intrigues me is wondering what, in five years’ time, we will be talking about in terms of, ‘I wouldn’t have thought we could have done that.’"