David Savastano, Editor09.22.21

Conductive inks and pastes are key to creating flexible and hybrid electronics. Conductive materials allow the printed portion of the device to function electronically. It is also a sizable market: estimates place the conductive ink segment at more than $2 billion.

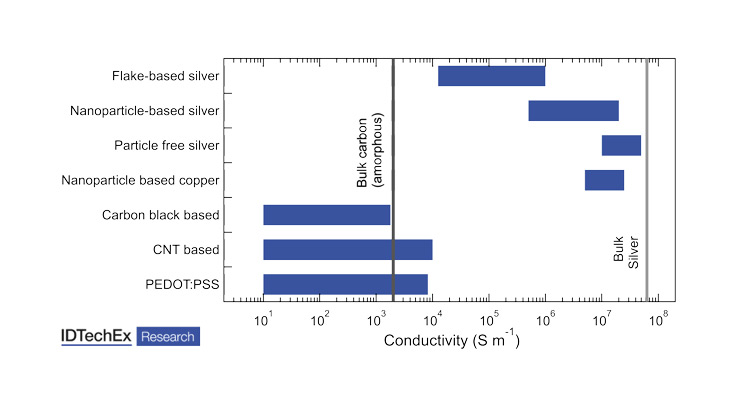

Conductive inks can be made from any material that is, well, conductive. Silver and carbon-based inks are the primary choices, with copper of interest. However, copper has issues with oxidation that make it less ideal. Nanoparticle-based and particle-free alternatives are also emerging, but they are higher cost.

Dr. Matthew Dyson, technology analyst with IDTechEx, notes that IDTechEx estimates the current conductive ink market size as $2.3 billion, with silver the primary material.

“Almost 80% is silver flake-based ink that is used to make the conductive fingers on silicon solar panels,” Dr. Dyson reported. “While the market for this application is established and may even decline in the future as new technologies are adopted, there is extensive growth in flake-based inks for other applications, and also in emerging categories of conductive inks such as nanoparticle-based and particle-free inks.”

Khasha Ghaffarzadeh, CEO of TechBlick, a year-round event series with more than 350+ analyst selected live online presentations and 10-plus masterclasses, talked about the latest dynamics of the conductive inks market.

“Conductive inks are found in anything from a baby diaper to a precision missible,” Ghaffarzadeh said. “This makes the market wonderfully diverse and excellent at always adapting itself, rejuvenating itself, and re-inventing itself.”

Photovoltaics is the largest market, as conductive materials are used on the back of solar cells. Aside from photovoltaics, sensors, wearables and in-mold electronics are potentially sizable markets.

“This market is growing,” said Ghaffarzadeh. “Broadly speaking, we can talk of established and emerging applications. In the latter bucket, we have the huge, almost irreplaceable, solar cell market as well as other important markets like printed HMIs, LTCC metallization, and others.

“Those are fundamental to the industry, but the excitement is really in the emerging applications. Now here I could list many opportunities such as in-mold electronics, eTextiles, 5G filters, EMI shielding, sintered die attach paste, electrodes and skin patches, electrodes in CGMs and other biosensors, uLED substrate metallization, and many more,” Ghaffarzadeh added.

“In the near term, the biggest growth opportunities would appear to be wearable electronic skin patches and in-mold electronics,” Dr. Dyson observed. “Electronic skin patches require stretchable conductive ink, along with printed conductive electrodes in many cases, and are projected by IDTechEx to reach a market size of $38 billion by 2030.

“In-mold electronics (IME), and the closely related film-insert molding, is another application opportunity. Integrating electronics within plastic panels reduces weight, complexity and assembly costs. IME is thus highly applicable to automotive interiors, household appliances and even some consumer goods,” he added.

Toward the end of the decade, Dr. Dyson sees applications in partially additive electronics manufacturing, for example, printing wiring onto existing 3D structures, and also in smart packaging.

“Even further into the future, electromagnetic meta-surfaces that assist in the propagation and directing of the higher frequencies that will be used for telecommunications may represent a huge market for conductive ink,” he noted.

“The wide variety of applications for printed electronics means that there are many opportunities for differentiation within conductive inks,” Dr. Dyson noted. “Wearable electronics require inks that are stretchable to various extents and can withstand repeated mechanical flexing. The requirements for IME are slightly different, in that inks need to withstand the temperature and pressure associated with thermoforming.”

However, there are still requirements that conductive ink manufacturers need to address.

“Considering conductive inks more broadly, the main challenges are durability and cost,” added Dr. Dyson. “Utilizing printed inks in harsh environments, such as automotive applications, means that they need to withstand repeated thermal cycling from -40°C to 80°C, while of course, silver-based inks are vulnerable to metal price rises.”

THE PRICE OF SILVER INKS

That silver price volatility can be significant. IDTechEx’s analysts say that rising silver metal prices could lead to changes in the composition of conductive ink markets.

“The most obvious is an acceleration in the transition from silver to copper, with the latter metal currently over 100x cheaper at around $8/kg,” IDTechEx’s analysts reported. “This price differential means that replacing silver with copper has long been highly desirable. However, it has proved extremely challenging since copper is far more reactive than silver and oxidizes relatively quickly in the air to insulating copper oxide.”

The analysts noted that a range of technical approaches have been tried to avoid oxidation when printing with copper rather than silver inks, including making copper nanoparticles with a silver shell and printing the copper under an inert atmosphere.

“However, these strategies saw little success as they increased the cost of the printing process while reducing durability. Recent promising approaches, which are beginning to gain commercial traction, involve incorporating additives into copper nanoparticle-based inks that are believed to act as a reducing agent during sintering,” the IDTechEx analysts concluded.

MATERIALS FOR CONDUCTIVE INKS

Silver remains by far the dominant material due to its high conductivity and resistance to oxidation, and carbon-based materials as well as copper are drawing interest.

Dr. Dyson said that the ideal material would be highly conductive, inexpensive and very chemically stable, but achieving all three simultaneously is very challenging.

“Both carbon nanotubes and graphene-based inks have been discussed as alternatives to silver, but thus far have experienced little traction as direct replacements,” Dr. Dyson noted. “Instead, they are more likely to find success in niche applications when silver ink is unsuitable. This could be due to a requirement for transparency, specific mechanical properties, or if there are concerns about the sustainability of silver once the product is disposed of.”

Ghaffarzadeh said that graphene has its place.

“In simplistic terms, one can think of it as an enhanced carbon inks, as its conductivity sits above carbon and some way below metal inks such as silver or copper inks,” he added. “It is however already being applied, for example, in large area heating applications.”

Ghaffarzadeh noted that copper ink is an active field again.

“I would say that copper has faced a credibility gap, as many over-promised and under-delivered,” Ghaffarzadeh observed. “The need for special curing machines as well as special treatment was always a hindrance. The cost structure was also not as favorable as one might expect based on raw copper prices.

“Copper inks were often lower conductivity, which meant more of them was needed, shrinking the potential price difference with silver,” Ghaffarzadeh added. “Nanocopper production could also have low yield due to oxidation, driving up costs. Now there are some exciting results with low-temperature and rapid sinter copper pastes and inks that exhibit good conductivity. It would argue that copper deserves to be given yet another deep look given the latest results.”

“Significant progress is being made on conductive copper inks, which offer both cost and sustainability benefits relative to silver,” Dr. Dyson added. “Utilizing copper hydride to generate an inert atmosphere in-situ enables oxidation to be avoided during deposition/sintering, but printed copper traces will require excellent encapsulation to prevent oxidation once incorporated into a product.”

Conductive inks can be made from any material that is, well, conductive. Silver and carbon-based inks are the primary choices, with copper of interest. However, copper has issues with oxidation that make it less ideal. Nanoparticle-based and particle-free alternatives are also emerging, but they are higher cost.

Dr. Matthew Dyson, technology analyst with IDTechEx, notes that IDTechEx estimates the current conductive ink market size as $2.3 billion, with silver the primary material.

“Almost 80% is silver flake-based ink that is used to make the conductive fingers on silicon solar panels,” Dr. Dyson reported. “While the market for this application is established and may even decline in the future as new technologies are adopted, there is extensive growth in flake-based inks for other applications, and also in emerging categories of conductive inks such as nanoparticle-based and particle-free inks.”

Khasha Ghaffarzadeh, CEO of TechBlick, a year-round event series with more than 350+ analyst selected live online presentations and 10-plus masterclasses, talked about the latest dynamics of the conductive inks market.

“Conductive inks are found in anything from a baby diaper to a precision missible,” Ghaffarzadeh said. “This makes the market wonderfully diverse and excellent at always adapting itself, rejuvenating itself, and re-inventing itself.”

Photovoltaics is the largest market, as conductive materials are used on the back of solar cells. Aside from photovoltaics, sensors, wearables and in-mold electronics are potentially sizable markets.

“This market is growing,” said Ghaffarzadeh. “Broadly speaking, we can talk of established and emerging applications. In the latter bucket, we have the huge, almost irreplaceable, solar cell market as well as other important markets like printed HMIs, LTCC metallization, and others.

“Those are fundamental to the industry, but the excitement is really in the emerging applications. Now here I could list many opportunities such as in-mold electronics, eTextiles, 5G filters, EMI shielding, sintered die attach paste, electrodes and skin patches, electrodes in CGMs and other biosensors, uLED substrate metallization, and many more,” Ghaffarzadeh added.

“In the near term, the biggest growth opportunities would appear to be wearable electronic skin patches and in-mold electronics,” Dr. Dyson observed. “Electronic skin patches require stretchable conductive ink, along with printed conductive electrodes in many cases, and are projected by IDTechEx to reach a market size of $38 billion by 2030.

“In-mold electronics (IME), and the closely related film-insert molding, is another application opportunity. Integrating electronics within plastic panels reduces weight, complexity and assembly costs. IME is thus highly applicable to automotive interiors, household appliances and even some consumer goods,” he added.

Toward the end of the decade, Dr. Dyson sees applications in partially additive electronics manufacturing, for example, printing wiring onto existing 3D structures, and also in smart packaging.

“Even further into the future, electromagnetic meta-surfaces that assist in the propagation and directing of the higher frequencies that will be used for telecommunications may represent a huge market for conductive ink,” he noted.

“The wide variety of applications for printed electronics means that there are many opportunities for differentiation within conductive inks,” Dr. Dyson noted. “Wearable electronics require inks that are stretchable to various extents and can withstand repeated mechanical flexing. The requirements for IME are slightly different, in that inks need to withstand the temperature and pressure associated with thermoforming.”

However, there are still requirements that conductive ink manufacturers need to address.

“Considering conductive inks more broadly, the main challenges are durability and cost,” added Dr. Dyson. “Utilizing printed inks in harsh environments, such as automotive applications, means that they need to withstand repeated thermal cycling from -40°C to 80°C, while of course, silver-based inks are vulnerable to metal price rises.”

THE PRICE OF SILVER INKS

That silver price volatility can be significant. IDTechEx’s analysts say that rising silver metal prices could lead to changes in the composition of conductive ink markets.

“The most obvious is an acceleration in the transition from silver to copper, with the latter metal currently over 100x cheaper at around $8/kg,” IDTechEx’s analysts reported. “This price differential means that replacing silver with copper has long been highly desirable. However, it has proved extremely challenging since copper is far more reactive than silver and oxidizes relatively quickly in the air to insulating copper oxide.”

The analysts noted that a range of technical approaches have been tried to avoid oxidation when printing with copper rather than silver inks, including making copper nanoparticles with a silver shell and printing the copper under an inert atmosphere.

“However, these strategies saw little success as they increased the cost of the printing process while reducing durability. Recent promising approaches, which are beginning to gain commercial traction, involve incorporating additives into copper nanoparticle-based inks that are believed to act as a reducing agent during sintering,” the IDTechEx analysts concluded.

MATERIALS FOR CONDUCTIVE INKS

Silver remains by far the dominant material due to its high conductivity and resistance to oxidation, and carbon-based materials as well as copper are drawing interest.

Dr. Dyson said that the ideal material would be highly conductive, inexpensive and very chemically stable, but achieving all three simultaneously is very challenging.

“Both carbon nanotubes and graphene-based inks have been discussed as alternatives to silver, but thus far have experienced little traction as direct replacements,” Dr. Dyson noted. “Instead, they are more likely to find success in niche applications when silver ink is unsuitable. This could be due to a requirement for transparency, specific mechanical properties, or if there are concerns about the sustainability of silver once the product is disposed of.”

Ghaffarzadeh said that graphene has its place.

“In simplistic terms, one can think of it as an enhanced carbon inks, as its conductivity sits above carbon and some way below metal inks such as silver or copper inks,” he added. “It is however already being applied, for example, in large area heating applications.”

Ghaffarzadeh noted that copper ink is an active field again.

“I would say that copper has faced a credibility gap, as many over-promised and under-delivered,” Ghaffarzadeh observed. “The need for special curing machines as well as special treatment was always a hindrance. The cost structure was also not as favorable as one might expect based on raw copper prices.

“Copper inks were often lower conductivity, which meant more of them was needed, shrinking the potential price difference with silver,” Ghaffarzadeh added. “Nanocopper production could also have low yield due to oxidation, driving up costs. Now there are some exciting results with low-temperature and rapid sinter copper pastes and inks that exhibit good conductivity. It would argue that copper deserves to be given yet another deep look given the latest results.”

“Significant progress is being made on conductive copper inks, which offer both cost and sustainability benefits relative to silver,” Dr. Dyson added. “Utilizing copper hydride to generate an inert atmosphere in-situ enables oxidation to be avoided during deposition/sintering, but printed copper traces will require excellent encapsulation to prevent oxidation once incorporated into a product.”