09.22.17

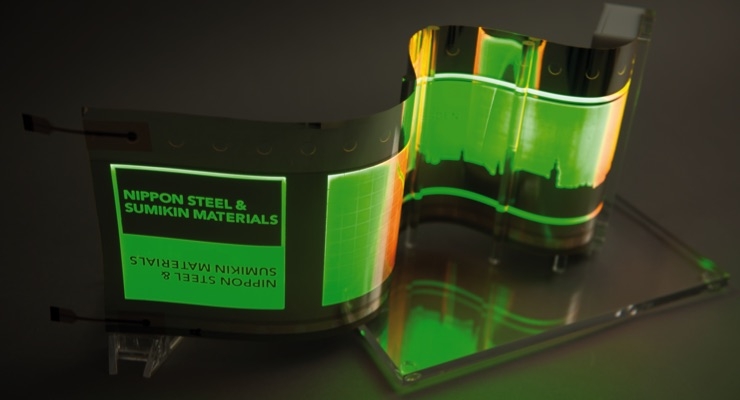

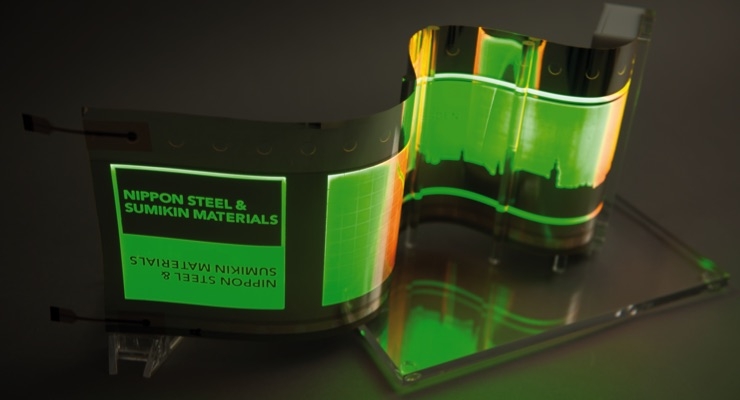

Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP will be presenting OLEDs on gauzy stainless steel foil during aimcal 2017 in Tampa, FL, from Oct. 15-18, 2017. The application was developed with the Nippon Steel & Sumikin Materials Co., Ltd. (NSMAT) and Nippon Steel & Sumitomo Metal Corporation (NSSMC).

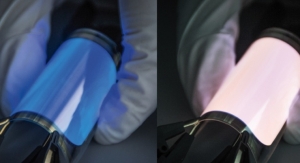

Stainless steel foil has also been utilized for several years in thin-film photovoltaics and batteries. Now stainless steel can also serve as a substrate for flexible electronic components. In comparison to the conventional substrate materials like glass or plastic web the material possesses special properties for this purpose and is well-suited as a substrate for organic light-emitting diodes (OLEDs), for example. With the planarization layer developed by NSSMC as well as the comparatively good thermal conductivity of stainless steel, homogenous large-area lighting surfaces with current densities of more than 10 mA/cm² have become better applicable.

OLEDs need to be protected from water vapor and oxygen in order that the organic layers remain fully functional. Stainless steel provides excellent barrier properties against environmental influences and is therefore suitable as a substrate for OLEDs from this standpoint as well.

“We see OLEDs on stainless steel in perhaps three years from now being used in automobiles as turn indicator and back-up lights, as cladding for fascia, and as advertising displays,” said Jun Nakatsuka, manager of business development at NSMAT.

Fraunhofer FEP has at its disposal roll-to-roll processing lines for manufacturing OLEDs on flexible materials and an OLED process that has high reproducibility. This is what has made possible the development of stainless steel foil with a clean and smooth planarization layer.

OLEDs on stainless steel foil. (Source: Fraunhofer FEP)

Stainless steel foil has also been utilized for several years in thin-film photovoltaics and batteries. Now stainless steel can also serve as a substrate for flexible electronic components. In comparison to the conventional substrate materials like glass or plastic web the material possesses special properties for this purpose and is well-suited as a substrate for organic light-emitting diodes (OLEDs), for example. With the planarization layer developed by NSSMC as well as the comparatively good thermal conductivity of stainless steel, homogenous large-area lighting surfaces with current densities of more than 10 mA/cm² have become better applicable.

OLEDs need to be protected from water vapor and oxygen in order that the organic layers remain fully functional. Stainless steel provides excellent barrier properties against environmental influences and is therefore suitable as a substrate for OLEDs from this standpoint as well.

“We see OLEDs on stainless steel in perhaps three years from now being used in automobiles as turn indicator and back-up lights, as cladding for fascia, and as advertising displays,” said Jun Nakatsuka, manager of business development at NSMAT.

Fraunhofer FEP has at its disposal roll-to-roll processing lines for manufacturing OLEDs on flexible materials and an OLED process that has high reproducibility. This is what has made possible the development of stainless steel foil with a clean and smooth planarization layer.

OLEDs on stainless steel foil. (Source: Fraunhofer FEP)