04.25.19

The forecasts for growth promise increasing markets and opportunities for flexible, organic and printed electronics. In Europe, top institutions and companies are engaged in research and further development of these technologies for tomorrow’s markets and applications. However, access by SMEs is difficult.

The European project SmartEEs - Smart Emerging Electronics Servicing - works on the establishment of a European innovation network.

Printed electronics surrounds us and almost unconsciously accompanies us through everyday life. It starts with smart labels or RFID tags in clothing, test strips for blood glucose measurement or while in the refrigerator in the form of labels or anti-counterfeiting protection on packaging. The day continues with many looks at the mobile phone with OLED display or the Smart Watch on the arm. On the way to work, sensors monitor seat occupancy detection, touch displays support navigation, and OLED tail lights light up the car to say goodbye when you arrive at your destination.

The market for printed electronics and flexible organic electronics has been growing continuously for years. Growth forecasts are particularly high for the thin-film, organic and large-area electronics (TOLAE) market, in which Europe has a strong research and innovation position. This offers great opportunities for European industry. So far, however, European small and medium-sized enterprises have had very limited access to these technologies and have not been able to build up and develop the skills to use them to benefit from them.

This is where the European project SmartEEs - Smart Emerging Electronics Servicing, launched some two years ago, starts. It offers an organized European innovation network for access to competences and technologies for printed and thin film electronics and beyond that support for the implementation of innovations up to commercialization.

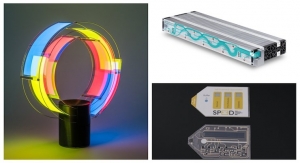

One of the most important pioneering industries to have included flexible organic electronics in their future programs and innovation roadmaps is the automotive industry. The lighting designers of the leading European automotive manufacturers now use flexible light sculptures made of OLEDs to create accents and statements for these technologies in their products and cars. With their possibilities such as segmentation, signage, color variability, transparency and light weight, flexible OLEDs offer new design worlds, e.g. on plastic or ultra-thin glass. Flexible touch panels, curved displays and printed sensors are also a must-have.

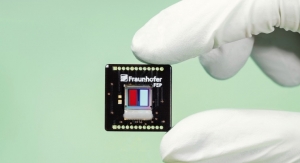

Fraunhofer FEP has more than 10 years of experience in research and development of flexible organic electronics and their integration into later applications in various industries.

“What began with the first rigid luminous surfaces, our scientists have now been able to establish to a broad-based competence center for flexible organic electronics,” said Dr. Christian May, head of Business Unit Flexible Organic Electronics. “In addition to the development of flexible OLEDs in sheet-to-sheet processes, we also have the possibility of cost-efficient technology development of OLEDs in roll-to-roll processes. In the meantime, we can proudly look back on a large number of pioneering projects with the automotive industry, which have enabled us to build up very extensive know-how in the development of organic components and OLED lighting solutions precisely for this industry. This has also led us to a joint development project for OLED integration in automotive interiors as part of SmartEEs.”

How exactly does the SmartEEs construct work? In addition to the dissemination of TOLAE technologies, concrete application projects are selected and implemented to demonstrate the transfer of technologies into new products, processes and business models. A Digital Innovation Hub (DIH) was created as a platform for this purpose. The DIH can organize the funding to accelerate the industrial and societal introduction of new digital products and services that realize the potential of applications with advanced organic photovoltaics, flexible displays, OLED lighting and integrated smart systems. A total of €4.5 million euros is available for this purpose, which SmartEEs are planning to invest in 20 application projects.

“So far, eight interesting projects on thin-film and printed electronics and also on the development and integration of flexible OLEDs in new materials for a wide variety of industries such as logistics, health or sports have been handled by the SmartEEs partners,” said SmartEEs coordinator Jérôme Gavillet. “The results achieved show that the hub concept of the EU project is taking effect.”

Source: Fraunhofer FEP.

The European project SmartEEs - Smart Emerging Electronics Servicing - works on the establishment of a European innovation network.

Printed electronics surrounds us and almost unconsciously accompanies us through everyday life. It starts with smart labels or RFID tags in clothing, test strips for blood glucose measurement or while in the refrigerator in the form of labels or anti-counterfeiting protection on packaging. The day continues with many looks at the mobile phone with OLED display or the Smart Watch on the arm. On the way to work, sensors monitor seat occupancy detection, touch displays support navigation, and OLED tail lights light up the car to say goodbye when you arrive at your destination.

The market for printed electronics and flexible organic electronics has been growing continuously for years. Growth forecasts are particularly high for the thin-film, organic and large-area electronics (TOLAE) market, in which Europe has a strong research and innovation position. This offers great opportunities for European industry. So far, however, European small and medium-sized enterprises have had very limited access to these technologies and have not been able to build up and develop the skills to use them to benefit from them.

This is where the European project SmartEEs - Smart Emerging Electronics Servicing, launched some two years ago, starts. It offers an organized European innovation network for access to competences and technologies for printed and thin film electronics and beyond that support for the implementation of innovations up to commercialization.

One of the most important pioneering industries to have included flexible organic electronics in their future programs and innovation roadmaps is the automotive industry. The lighting designers of the leading European automotive manufacturers now use flexible light sculptures made of OLEDs to create accents and statements for these technologies in their products and cars. With their possibilities such as segmentation, signage, color variability, transparency and light weight, flexible OLEDs offer new design worlds, e.g. on plastic or ultra-thin glass. Flexible touch panels, curved displays and printed sensors are also a must-have.

Fraunhofer FEP has more than 10 years of experience in research and development of flexible organic electronics and their integration into later applications in various industries.

“What began with the first rigid luminous surfaces, our scientists have now been able to establish to a broad-based competence center for flexible organic electronics,” said Dr. Christian May, head of Business Unit Flexible Organic Electronics. “In addition to the development of flexible OLEDs in sheet-to-sheet processes, we also have the possibility of cost-efficient technology development of OLEDs in roll-to-roll processes. In the meantime, we can proudly look back on a large number of pioneering projects with the automotive industry, which have enabled us to build up very extensive know-how in the development of organic components and OLED lighting solutions precisely for this industry. This has also led us to a joint development project for OLED integration in automotive interiors as part of SmartEEs.”

How exactly does the SmartEEs construct work? In addition to the dissemination of TOLAE technologies, concrete application projects are selected and implemented to demonstrate the transfer of technologies into new products, processes and business models. A Digital Innovation Hub (DIH) was created as a platform for this purpose. The DIH can organize the funding to accelerate the industrial and societal introduction of new digital products and services that realize the potential of applications with advanced organic photovoltaics, flexible displays, OLED lighting and integrated smart systems. A total of €4.5 million euros is available for this purpose, which SmartEEs are planning to invest in 20 application projects.

“So far, eight interesting projects on thin-film and printed electronics and also on the development and integration of flexible OLEDs in new materials for a wide variety of industries such as logistics, health or sports have been handled by the SmartEEs partners,” said SmartEEs coordinator Jérôme Gavillet. “The results achieved show that the hub concept of the EU project is taking effect.”

Source: Fraunhofer FEP.