08.15.19

Rare earth elements are the “secret sauce” of numerous advanced materials for energy, transportation, defense and communications applications. Their largest use for clean energy is in permanent magnets, which retain magnetic properties even in the absence of an inducing field or current.

Now, U.S. Department of Energy researchers invented a process to extract rare earth elements from the scrapped magnets of used hard drives and other sources. They have patented and scaled up the process in lab demonstrations and are working with ORNL’s licensee Momentum Technologies of Dallas to scale the process further to produce commercial batches of rare earth oxides.

“We have developed an energy-efficient, cost-effective, environmentally friendly process to recover high-value critical materials,” said co-inventor Ramesh Bhave of DOE’s Oak Ridge National Laboratory, who leads the membrane technologies team in ORNL’s Chemical Sciences Division. “It’s an improvement over traditional processes, which require facilities with a large footprint, high capital and operating costs and a large amount of waste generated.”

Permanent magnets help computer hard drives read and write data, drive motors that move hybrid and electric cars, couple wind turbines with generators to make electricity, and assist smartphones to translate electrical signals into sound.

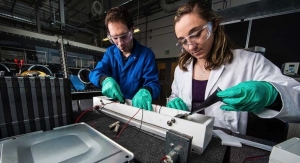

Through the patented process, magnets are dissolved in nitric acid, and the solution is continuously fed through a module supporting polymer membranes. The membranes contain porous hollow fibers with an extractant that serves as a chemical “traffic cop” of sorts; it creates a selective barrier and lets only rare-earth elements pass through. The rare-earth-rich solution collected on the other side is further processed to yield rare earth oxides at purities exceeding 99.5%.

That’s remarkable considering that typically, 70% of a permanent magnet is iron, which is not a r are earth element. “We are essentially able to eliminate iron completely and recover only rare earth,” Bhave said. Extracting desirable elements without co-extracting undesirable ones means less waste is created that will need downstream treatment and disposal.

Supporters of the work include DOE’s Critical Materials Institute, or CMI, for separations research and DOE’s Office of Technology Transitions, or OTT, for process scale-up. ORNL is a founding team member of CMI, a DOE Energy Innovation Hub led by DOE’s Ames Laboratory and managed by the Advanced Manufacturing Office. Bhave’s “mining” of an acidic solution with selective membranes joins other promising CMI technologies for recovering rare earth, including a simple process that crushes and treats magnets and an acid-free alternative.

Industry depends on critical materials, and the scientific community is developing processes to recycle them. However, no commercialized process recycles pure rare earth elements from electronic-waste magnets. That’s a huge missed opportunity considering 2.2 billion personal computers, tablets and mobile phones are expected to ship worldwide in 2019, according to Gartner. “All of these devices have rare earth magnets in them,” Bhave said.

Bhave’s project, which began in 2013, is a team effort. John Klaehn and Eric Peterson of DOE’s Idaho National Laboratory collaborated in an early phase of the research focused on chemistry, and Ananth Iyer, a professor at Purdue University, later assessed the technical and economic feasibility of scale-up.

At ORNL, former postdoctoral fellows Daejin Kim and Vishwanath Deshmane studied separations process development and scale-up, respectively.

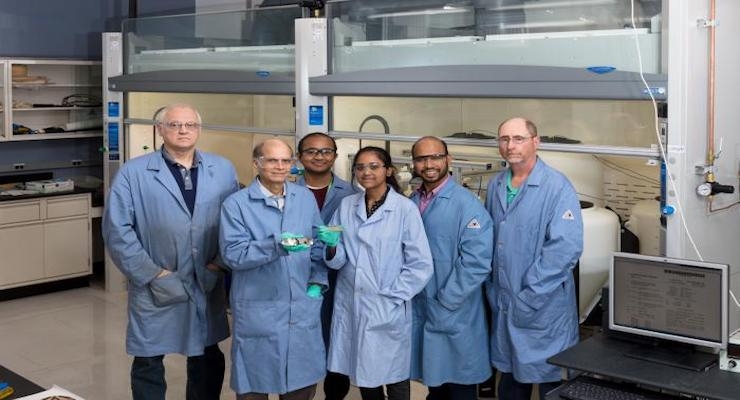

Bhave’s current ORNL team, comprising Dale Adcock, Pranathi Gangavarapu, Syed Islam, Larry Powell and Priyesh Wagh, focuses on scaling up the process and working with industry partners who will commercialize the technology.

To ensure rare earth could be recovered across a wide spectrum of feedstocks, researchers subjected magnets of varying composition—from sources including hard drives, magnetic resonance imaging machines, cell phones and hybrid cars—to the process.

Most rare earth elements are lanthanides, elements with atomic numbers between 57 and 71 in the periodic table. “ORNL’s tremendous expertise in lanthanide chemistry gave us a huge jump start,” Bhave said. “We started looking at lanthanide chemistries and ways by which lanthanides are selectively extracted.”

Over two years, the researchers tailored membrane chemistry to optimize the recovery of rare earth. Now, their process recovers more than 97% of the rare earth elements.

To date, Bhave’s recycling project has resulted in a patent and two publications documenting the recovery of three rare earth elements—neodymium, praseodymium and dysprosium—as a mixture of oxides.

The second phase of separations began in July 2018 with an effort to separate dysprosium from neodymium and praseodymium. A mixture of the three oxides sells for $50 a kilogram. If dysprosium could be separated from the mixture, its oxide could be sold for five times as much.

The program’s second phase will also explore if ORNL’s underlying process for separating rare earth can be developed for separating other in-demand elements from lithium-ion batteries. “The expected high growth of electric vehicles is going to require a tremendous amount of lithium and cobalt,” Bhave said.

Industrial efforts needed to deploy the ORNL process into the marketplace, funded over two years by DOE’s OTT Technology Commercialization Fund, began in February 2019.

The goal is to recover hundreds of kilograms of rare earth oxides each month and validate, verify and certify that manufacturers could use the recycled materials to make magnets equivalent to those made with virgin materials.

Pictured: From left, ORNL team members Dale Adcock, Ramesh Bhave, Priyesh Wagh, Pranathi Gangavarapu, Syed Islam and Larry Powell are helping ORNL’s patent licensee Momentum Technologies scale up this laboratory-scale process for commercial deployment. Credit: Carlos Jones/Oak Ridge National Laboratory, U.S. Dept. of Energy

Now, U.S. Department of Energy researchers invented a process to extract rare earth elements from the scrapped magnets of used hard drives and other sources. They have patented and scaled up the process in lab demonstrations and are working with ORNL’s licensee Momentum Technologies of Dallas to scale the process further to produce commercial batches of rare earth oxides.

“We have developed an energy-efficient, cost-effective, environmentally friendly process to recover high-value critical materials,” said co-inventor Ramesh Bhave of DOE’s Oak Ridge National Laboratory, who leads the membrane technologies team in ORNL’s Chemical Sciences Division. “It’s an improvement over traditional processes, which require facilities with a large footprint, high capital and operating costs and a large amount of waste generated.”

Permanent magnets help computer hard drives read and write data, drive motors that move hybrid and electric cars, couple wind turbines with generators to make electricity, and assist smartphones to translate electrical signals into sound.

Through the patented process, magnets are dissolved in nitric acid, and the solution is continuously fed through a module supporting polymer membranes. The membranes contain porous hollow fibers with an extractant that serves as a chemical “traffic cop” of sorts; it creates a selective barrier and lets only rare-earth elements pass through. The rare-earth-rich solution collected on the other side is further processed to yield rare earth oxides at purities exceeding 99.5%.

That’s remarkable considering that typically, 70% of a permanent magnet is iron, which is not a r are earth element. “We are essentially able to eliminate iron completely and recover only rare earth,” Bhave said. Extracting desirable elements without co-extracting undesirable ones means less waste is created that will need downstream treatment and disposal.

Supporters of the work include DOE’s Critical Materials Institute, or CMI, for separations research and DOE’s Office of Technology Transitions, or OTT, for process scale-up. ORNL is a founding team member of CMI, a DOE Energy Innovation Hub led by DOE’s Ames Laboratory and managed by the Advanced Manufacturing Office. Bhave’s “mining” of an acidic solution with selective membranes joins other promising CMI technologies for recovering rare earth, including a simple process that crushes and treats magnets and an acid-free alternative.

Industry depends on critical materials, and the scientific community is developing processes to recycle them. However, no commercialized process recycles pure rare earth elements from electronic-waste magnets. That’s a huge missed opportunity considering 2.2 billion personal computers, tablets and mobile phones are expected to ship worldwide in 2019, according to Gartner. “All of these devices have rare earth magnets in them,” Bhave said.

Bhave’s project, which began in 2013, is a team effort. John Klaehn and Eric Peterson of DOE’s Idaho National Laboratory collaborated in an early phase of the research focused on chemistry, and Ananth Iyer, a professor at Purdue University, later assessed the technical and economic feasibility of scale-up.

At ORNL, former postdoctoral fellows Daejin Kim and Vishwanath Deshmane studied separations process development and scale-up, respectively.

Bhave’s current ORNL team, comprising Dale Adcock, Pranathi Gangavarapu, Syed Islam, Larry Powell and Priyesh Wagh, focuses on scaling up the process and working with industry partners who will commercialize the technology.

To ensure rare earth could be recovered across a wide spectrum of feedstocks, researchers subjected magnets of varying composition—from sources including hard drives, magnetic resonance imaging machines, cell phones and hybrid cars—to the process.

Most rare earth elements are lanthanides, elements with atomic numbers between 57 and 71 in the periodic table. “ORNL’s tremendous expertise in lanthanide chemistry gave us a huge jump start,” Bhave said. “We started looking at lanthanide chemistries and ways by which lanthanides are selectively extracted.”

Over two years, the researchers tailored membrane chemistry to optimize the recovery of rare earth. Now, their process recovers more than 97% of the rare earth elements.

To date, Bhave’s recycling project has resulted in a patent and two publications documenting the recovery of three rare earth elements—neodymium, praseodymium and dysprosium—as a mixture of oxides.

The second phase of separations began in July 2018 with an effort to separate dysprosium from neodymium and praseodymium. A mixture of the three oxides sells for $50 a kilogram. If dysprosium could be separated from the mixture, its oxide could be sold for five times as much.

The program’s second phase will also explore if ORNL’s underlying process for separating rare earth can be developed for separating other in-demand elements from lithium-ion batteries. “The expected high growth of electric vehicles is going to require a tremendous amount of lithium and cobalt,” Bhave said.

Industrial efforts needed to deploy the ORNL process into the marketplace, funded over two years by DOE’s OTT Technology Commercialization Fund, began in February 2019.

The goal is to recover hundreds of kilograms of rare earth oxides each month and validate, verify and certify that manufacturers could use the recycled materials to make magnets equivalent to those made with virgin materials.

Pictured: From left, ORNL team members Dale Adcock, Ramesh Bhave, Priyesh Wagh, Pranathi Gangavarapu, Syed Islam and Larry Powell are helping ORNL’s patent licensee Momentum Technologies scale up this laboratory-scale process for commercial deployment. Credit: Carlos Jones/Oak Ridge National Laboratory, U.S. Dept. of Energy