David Savastano, Editor04.25.18

For research institutes, collaboration is a huge advantage, as organizations have their own particular strengths. With a clear understanding of the benefits of these partnerships, Sweden formed RISE (Research Institutes of Sweden), bringing together its various national institutes under the RISE banner.

Among the key groups is RISE Acreo, an electronics institute, with printed electronics among its disciplines. RISE Acreo has a number of interesting advances in the technology to its credit and has created successful spin-outs. Now, with the ability to work together with its colleagues throughout the Swedish research field, RISE Acreo is primed to make further gains.

Bjorn Norberg, RISE Acreo’s sales manager – printed electronics, noted that the decision to form RISE is an excellent move.

“The state of Sweden unified the institutes sectors, as there are many,” Norberg said. “The consolidation into RISE is a good thing, as it makes us more visible, and makes sense from a management perspective. This was in the making for 15 years, and we are now under the same umbrella. With our latest merger, we will have 2,700 people; Acreo had 140 people.”

RISE consists of numerous divisions. For example, Acreo is part of the ICT (Information and Communication Technology) division, which also includes RISE Interactive, RISE SICS and RISE Viktoria.

“For us, it is better as it gives us a bigger footprint,” Norberg observed. “There are all types of opportunities. We have a sister institute that is focused on glass, and another on bioeconomy. RISE manages 100 testing and demonstration facilities, and the Printed Electronics Arena is just one of them.”

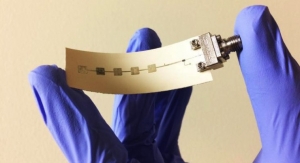

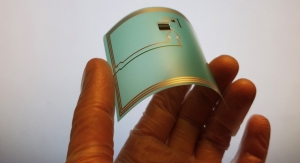

Among the services that RISE Acreo offers is the Printed Electronics Arena Manufacturing (PEA Manufacturing), which it terms a greenhouse for the development of printed electronics prototypes and small-scale production. It is available for start-up and established companies, universities and institutes to test print-related projects with the aid of the RISE Acreo team, medtech devices, electronics design, sensor trials and similar.

“The lab, coupled with clean rooms from the Linkoping University, the Laboratory of Organic Electronics, is a unique possibility to try new things out - going literally from molecule to prototype” Norberg said. The PEA microplant holds a comprehensive assortment of equipment, including inkjet printers, highly automated sheetfed screen printing equipment, pick&place, UV and heat dryers, and dry phase patterning equipment.

Since 2000, Acreo has been working on printed electronics, and it has been successfully spinning out companies

“We specialize in electrochromic displays, which is our flagship,” Norberg observed. “We are involved in R&D, such as synthesis of molecules and developing inks, printed antennas and displays. We are developing wearables, sensors and advanced hybrid systems. The vison is to move into roll-to-roll, with screen or inkjetting as a baseline, and we started creating hybrid electronics a few years ago.

“There are quite a lot of startups out of Acreo,” Norberg pointed out. “For example, DP Patterning came up with Dry Phase patterning rather than etching, which is a lot better for the environment. Invensense is getting good traction - they are printing passive humidity sensors for the construction industry, which shows whether a house is dry for insurance purposes.”

Because of Sweden’s abundance of woodlands, RISE Acreo has developed strengths in wood products, including cellulose.

“Sweden is rich in natural resources, such as forests,” Norberg said. “Because of our strength in forestry, we also excel at cellulose. Using NFC, Nanofibrillated Cellulose and conducting polymers together we are moving into a very exciting new class of materials we call Digital Cellulose – possible to charge with electricity and other functions.”

Norberg said that RISE Acreo is currently developing some interesting projects.

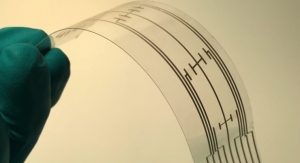

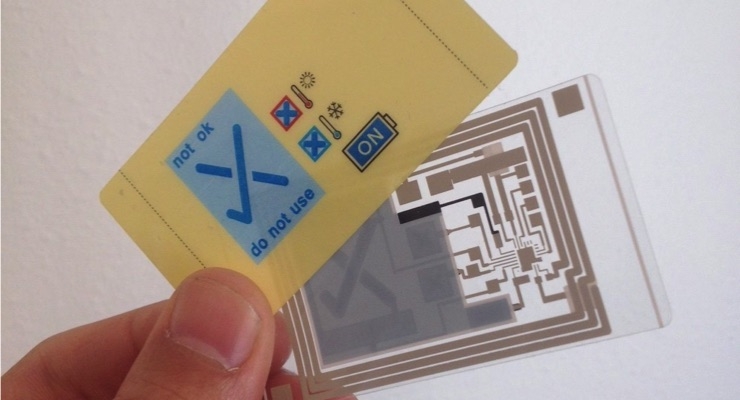

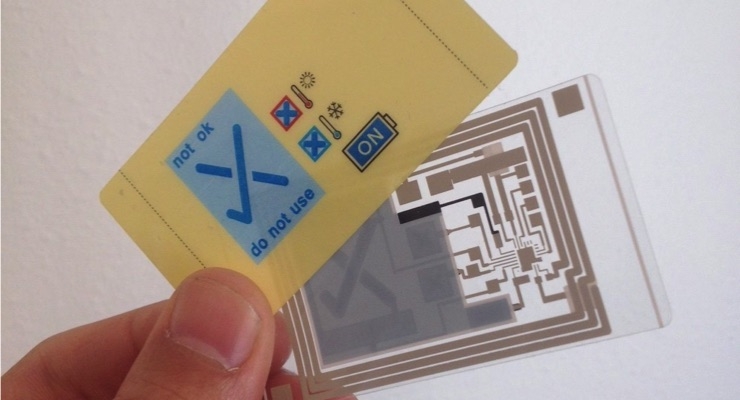

“The smart cold chain indicator is interesting - the design has been specified by Doctors without Borders,” he said. “We are on the second phase, making 10,000 units, and have FLEX on board as a potential ramp-up partner. It looks very promising. It is a smart label with a printed electrochromic display which gives a vital signal to users in the Last Mile scenario, where the tech infrastructure is not always developed. It is important, as vials with different vaccines have different temperature thresholds and sensitivities, and there are a lot of use scenarios and players. Another project is the Integrated Sensor Platform, which can detect different biomarkers, in an extremely lean format, a potentially disposable mini-lab.”

Norberg sees a bright future ahead for printed electronics.

“Printed electronics is enabling methodology,” Norberg concluded. “It used to be very far on the horizon but we’re now seeing several applications getting to and closer to market. Fast.”

Cold chain indicators. (Source: RISE Acreo)

Among the key groups is RISE Acreo, an electronics institute, with printed electronics among its disciplines. RISE Acreo has a number of interesting advances in the technology to its credit and has created successful spin-outs. Now, with the ability to work together with its colleagues throughout the Swedish research field, RISE Acreo is primed to make further gains.

Bjorn Norberg, RISE Acreo’s sales manager – printed electronics, noted that the decision to form RISE is an excellent move.

“The state of Sweden unified the institutes sectors, as there are many,” Norberg said. “The consolidation into RISE is a good thing, as it makes us more visible, and makes sense from a management perspective. This was in the making for 15 years, and we are now under the same umbrella. With our latest merger, we will have 2,700 people; Acreo had 140 people.”

RISE consists of numerous divisions. For example, Acreo is part of the ICT (Information and Communication Technology) division, which also includes RISE Interactive, RISE SICS and RISE Viktoria.

“For us, it is better as it gives us a bigger footprint,” Norberg observed. “There are all types of opportunities. We have a sister institute that is focused on glass, and another on bioeconomy. RISE manages 100 testing and demonstration facilities, and the Printed Electronics Arena is just one of them.”

Among the services that RISE Acreo offers is the Printed Electronics Arena Manufacturing (PEA Manufacturing), which it terms a greenhouse for the development of printed electronics prototypes and small-scale production. It is available for start-up and established companies, universities and institutes to test print-related projects with the aid of the RISE Acreo team, medtech devices, electronics design, sensor trials and similar.

“The lab, coupled with clean rooms from the Linkoping University, the Laboratory of Organic Electronics, is a unique possibility to try new things out - going literally from molecule to prototype” Norberg said. The PEA microplant holds a comprehensive assortment of equipment, including inkjet printers, highly automated sheetfed screen printing equipment, pick&place, UV and heat dryers, and dry phase patterning equipment.

Since 2000, Acreo has been working on printed electronics, and it has been successfully spinning out companies

“We specialize in electrochromic displays, which is our flagship,” Norberg observed. “We are involved in R&D, such as synthesis of molecules and developing inks, printed antennas and displays. We are developing wearables, sensors and advanced hybrid systems. The vison is to move into roll-to-roll, with screen or inkjetting as a baseline, and we started creating hybrid electronics a few years ago.

“There are quite a lot of startups out of Acreo,” Norberg pointed out. “For example, DP Patterning came up with Dry Phase patterning rather than etching, which is a lot better for the environment. Invensense is getting good traction - they are printing passive humidity sensors for the construction industry, which shows whether a house is dry for insurance purposes.”

Because of Sweden’s abundance of woodlands, RISE Acreo has developed strengths in wood products, including cellulose.

“Sweden is rich in natural resources, such as forests,” Norberg said. “Because of our strength in forestry, we also excel at cellulose. Using NFC, Nanofibrillated Cellulose and conducting polymers together we are moving into a very exciting new class of materials we call Digital Cellulose – possible to charge with electricity and other functions.”

Norberg said that RISE Acreo is currently developing some interesting projects.

“The smart cold chain indicator is interesting - the design has been specified by Doctors without Borders,” he said. “We are on the second phase, making 10,000 units, and have FLEX on board as a potential ramp-up partner. It looks very promising. It is a smart label with a printed electrochromic display which gives a vital signal to users in the Last Mile scenario, where the tech infrastructure is not always developed. It is important, as vials with different vaccines have different temperature thresholds and sensitivities, and there are a lot of use scenarios and players. Another project is the Integrated Sensor Platform, which can detect different biomarkers, in an extremely lean format, a potentially disposable mini-lab.”

Norberg sees a bright future ahead for printed electronics.

“Printed electronics is enabling methodology,” Norberg concluded. “It used to be very far on the horizon but we’re now seeing several applications getting to and closer to market. Fast.”

Cold chain indicators. (Source: RISE Acreo)