David Savastano, Editor11.07.14

When it comes to manufacturing printed electronics, there is equipment for just about every need. Stan Farnsworth, vice president of marketing for NovaCentrix, said that the concept of printed electronics has captured the interest of those working in many applications and markets.

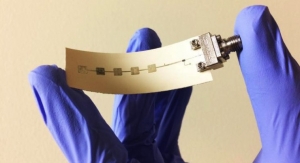

“One key market is printed antennas, such as for RFID and for communications devices such as cell phones,” Farnsworth noted. “For these applications, the low cost and high performance of our Metalon ICI copper oxide reduction inks is critical, along with our PulseForge photonic curing tools. These applications are appealing because of the volumes of devices that would be needed, driving tool sales as well as material (ink) sales.

“There is also ongoing interest in photovoltaic applications, particularly from groups doing more fundamental materials research,” Farnsworth added. “While the solar markets have been struggling recently, there are still fundamental opportunities to be realized by true low-cost, efficient photovoltaic technologies. An example is a long-term joint effort at the University of Texas and Colorado State University, led by Dr. Brian Korgel, to understand the application of photonic curing to printable CIGS technologies. Other key application opportunities include sensors, for markets such as automotive and garments.”

“Within our product offer for organic thin films, we see two product lines as most interesting for applications in the field of flexible electronics as well,” said Juergen Kreis, director business development at AIXTRON SE. “AIXTRON’s OVPD (Organic Vapor Phase Deposition) addresses the efficient deposition of organic thin films made of organic small molecules, thus predominantly useful for the manufacturing of OLEDs (display and lighting alike) and OPV devices and, due to its disruptive approach, offers some specific advantages compared to the more common vacuum thermal evaporation.

“AIXTRON’s PVPD (Polymer Vapor Phase Deposition) approach, implemented in our PRODOS line, allows the deposition and in-situ formation of polymer-based thin films in an all dry approach, thus offering again some unique possibilities compared to solvent-based polymer deposition processes,” Kreis added. “Both technologies make use of AIXTRON’s CCS (Close Coupled Showerhead) approach, which allows to scale gas phase processes based on well understood scaling rules to any relevant production and substrate size. This approach also addresses the need for efficient material utilization, which, given the considerably high material costs of performance materials, is key for efficient device manufacturing, for instance in the field of OLED lighting.”

Nicolas Bernardin, CeraPrinter product manager for Ceradrop, noted that the key markets that Ceradrop is serving within the flexible and printed electronics field include flexible solar cells (OPV), smart cards, antennas, interconnects and passive components.

Mandy Gebhardt, head of marketing department, 3D-Micromac AG, noted that 3D-Micromac’s key markets are OPV, OLED, RFID, flexible displays and tools for general R&D purposes.

“We have some ideas as to what may become ‘key markets,’ but we’re taking a wide view,” said Bob Hoffman, one of Martin Automatic’s regional managers and its market development specialist for PE. “Martin’s expertise in handling webs – substrates delivered and processed as roll stock – spans a broad range of processes. We’re talking to or working with companies, individuals, research scientists, engineers, academics – you name it – who are involved in just about every printing, coating and converting technology related to photovoltaics, energy storage, and all manner of PE.”

Rory Wolf, vice president, business development and technology director – atmospheric plasma systems at Enercon Industries Corporation, said that Enercon’s participation in the flexible and printed electronics space has primarily been in enabling roll-to-roll manufacturing of thin flexible electronics with atmospheric plasma surface modification technologies.

“By using in-line plasma technologies, manufacturers of printed and flexible electronics have significantly lowered surface cleaning and activation costs,” Wolf said. “The flexible nature of these devices dramatically enables not only their application within a broader range of stationary and remote devices, but also their integration with other flexible materials. A number of breakthroughs have been achieved by leveraging atmospheric pressure plasma technology as an integrated roll-to-roll, continuous production line process for manufacturing flexible electronics materials.”

John Palazzolo, director, marketing and sales, Adphos North America, Inc., said that Adphos specializes in drying and curing inks and coatings in the graphic arts market. “Our primary applications in this area have been drying water-based inkjet ink on direct mail and trans promo billing statements,” Palazzolo noted. “We continue to see interest in ‘smart printing’ applications at these customers expanding from ‘print-to-communicate’ into functional printing – allowing marketers the possibility of higher response rates using PE.”

Helping PE Manufacturers Overcome Challenges

One of the largest hurdles facing PE manufacturers is the ability to mass produce the applications. Xenon Corporation is active throughout the printed electronics field, from R&D for numerous applications to production for displays, and Xenon Corporation CEO Lou Panico said that ink to substrate adhesion, increasing line speed and low temperature solutions have been some of the biggest challenges that Xenon has helped its customers overcome.

Kreis noted that in order to address the ultimate goal of taking flexible and organic electronics to mass production levels, attractive manufacturing costs are key.

“As manufacturing costs must be understood as the total cost of ownership rather than CAPEX or variable costs only, it is essential to plan for production methods, which allow the ability to explore a new idea on small scale, scale it up in a straightforward manner to relevant dimensions without the need for determining all process parameters again for each dimension change, and gain on manufacturing costs with increasing size by increasing material utilization,” Kreis said. “Besides the cost factor only, novel technologies make the most sense if they do not only replicate existing processes, but also introduce novel possibilities or enhanced process features.

“Here, gas phase deposition potentially offers more freedom compared to solvent-based wet chemistry due to its intrinsic purity and potentially excellent ability to form films with highest contour conformity,” Kreis added. “For that reason, we consider OVPD and PVPD as enabling technologies for a wide range of functional thin films, offering efficient manufacturing of known device architectures and potentially opening new opportunities for novel solutions alike.”

“Many potential customers come to us with an initial interest in printed electronics but not necessarily a lot of expertise,” Farnsworth said. “Because of our origins as a materials company, our ink formulation expertise, and our capabilities with the PulseForge photonic curing tools, we often act as technology advisors to our clients. This is far beyond being a simple ink or tool provider. We also work with them in materials selection, be it for our inks or inks from other suppliers, process optimization for print and cure operations, and even in some cases for developing new engineering design guidelines for using printed electronics technologies. It never gets old to see the enthusiasm of a client, or to hear the relief and excitement in their voices, when they realize we can actually get them to their aggressive design and performance targets.”

“One of the biggest challenges was to make inkjet printing easier for printed electronics,” Bernardin said. “Another important point was to propose equipment on the market able to adapt to electronic materials to be deposited as well as to complex components design to be printed. That was only possible because of our bottom-up approach, and more concretely thanks to our exclusive CAD-CAM software CeraSlice.”

Gebhardt said that 3D-Micromac’s equipment helps manufacturers have a controlled process environment, with the flexibility to adjust to changes in the process chain, as well as process control (e.g. automated data logging for later cross reference).

“It is well known that a large barrier to growth of PE has been the cost of materials and substrates,” Palazzolo said. “The price of inks and coatings as well as substrates must come down to make the dream of ‘NFC tags and labels on every product’ or ‘light up postcards in every mailbox’ a reality. The required substrates to meet these cost targets are typically low cost polymer films, especially PET, which are thermally sensitive. Since the drying and curing temperature of these functional inks and coatings are often higher than the deformation temperature of the substrate, exotic curing technologies have historically been required.”

Wolf said that the most significant challenges overcome by the integration of atmospheric plasma technologies includes surface roughness, which is typically not good enough for making transistors, as the roughness average needs to be 2 to 3 angstroms, and plastic substrates are five to 10 times rougher than glass.

“Enercon’s atmospheric plasmas technologies are creating defined surface micro-roughness, improving lamination/encapsulation strength, enabling extremely minute printed feature sizes and improving ink-to-substrate compatibility through surface cleaning and functionalization effects,” Wolf added.

“Many leaders in the field have confirmed to us that maintaining exacting web tensions is an essential requirement to avoid any compromise of the delicate substrate properties or functional characteristics of the ink or coating,” Hoffman said. “These converted materials are very expensive, so process waste has to be minimized. As these technologies take off and become commercialized, we are creating or adapting web handling solutions for them.

“An example is our work with very delicate web structures, including light foils that are subject to wrinkling and creasing,” Hoffman added. “We’re matching production line speeds in successfully unwinding, rewinding and splicing these webs without damage or disruption to the process.”

Recent Equipment Innovations

To meet the needs of printed electronics manufacturers, equipment suppliers are introducing new machines for production as well as research into the market place. For example, Xenon recently announced the release of its new Sinteron 3000, bringing more flexibility and energy per pulse to the metallic ink offering solutions not previously attainable.

“The Sinteron 3000 provides high-energy pulsed light for reliable, repeatable sintering of copper nano particles on heat-sensitive materials such as PET,” Panico said. “The system features a high intensity pulsed lamp that provides a broadband spectrum of light, from 240 nm to 1000 nm, with adjustable pulse energy up to 3300 Joules per pulse and pulse durations up to 4 ms.”

Kreis said that as a result of being a supplier of production equipment, continuous product innovation is an intrinsic building block in AIXTRON’s product strategy across all of its business segments.

“For areas that still see a strong need for research, we do offer dedicated R&D platforms that allow a company to explore a certain approach on a smaller scale, yet always implement a method in a way that processed on such a tool always can be scaled to production levels with straightforward scaling rules,” Kreis said.

In 2012, AIXTRON introduced PVPD processes with PRODOS-200, a modular R&D platform, which, depending on its specific configuration, can be used to investigate a number of different polymer thin films.

“While the basic principle of OVPD already has proven its unique capabilities in a number of projects, for efficient OLED mass manufacturing, efficient evaporation of the organic precursors is of paramount importance,” Kreis noted. “Understanding this, AIXTRON has developed its proprietary STExS (Short Thermal Exposure Source) approach, which addresses high throughput manufacturing by enabling high deposition rates also for very large substrate areas, while at the same time the thermal stress to the precious organic precursors can be considerably reduced in comparison to conventional evaporation processes. Respectively, with STExS, we provide a solution which, on the one hand, helps to reduce production time, and, on the other hand, prevents material decomposition by reducing the thermal load of the materials.”

Farnsworth said that NovaCentrix has two key initiatives that are keeping the company busy right now.

“First, we launched our new low-cost PulseForge tool in December, optimized for R&D efforts but still retaining the pulse shaping capabilities of the full-size PulseForge tools,” Farnsworth said. “Customers have been responding very well to this new product, as it extends our state-of-the-art photonic curing capabilities to a customer segment that was having a hard time accessing our full-size tools.”

NovaCentrix’s second major initiative is its new print service this summer, which is being launched this summer.

“We are installing a full-size print press, based initially on flexographic and screen printing,” Farnsworth noted. “It will be fully equipped with our PulseForge tools. We are making this available for clients who need outsourced pilot production work or even full production efforts. We will be able to produce the number of units per hour or day using this press that might prevent a client from having to invest themselves in the equipment and expertise to do this in-house. This is in response to many of our clients passing the concept and development phases of their product development efforts, but then not having an accessible scale-up resource, either in cost or in timing, to meet their needs. By taking this step ourselves, we are building on the materials, printing and post-processing expertise of our team. Admittedly we are also having to add to our team, so we are moving to a new near-by facility to house both the print press and our growing team, as well as our other material and tool operations, in April.”

Gebhardt said that 3D-Micromac’s most recent innovation is its microFLEX platform, a modular roll-to-roll tool.

“The main advantage of this platform is that the modular approach enables the customer to either reorder the process chain or extend the process chain with additional features,” Gebhardt said. “This can be realized by simply adjusting the components in the working space of the tool, but even more so by readjusting the order of the modules or adding additional modules/functions later on. This way, the customer gets increased investment safety as he can adjust to developments in the future. The design even allows the customer to basically upgrade an R&D tool to a pilot line stage, and later on also to a full production line.”

Bernardin said that Ceradrop’s latest generation of curing modules integrated inline in its inkjet printers offers greater capability for the customer to build directly with Ceradrop’s equipment. In addition, different technologies of inkjet printheads embedded on Ceradrop’s printers as well as its ease of change offer greater flexibility and more materials compatible with its equipment.

Palazzolo said that Adphos has introduced a proven technology to solve the barrier of moving drying and curing from concept to the production process. “We have more than 2,000 installations in graphic arts going back 15 years,” Palazzolo said. “The benefit to our customers is allowing a cost effective growth path from curing 1,000 printed samples on a pilot line to full-scale production at 500 feet per minute on a 20-inch wide commercial web press.”

Wolf said that Enercon has developed two types of technological solutions for enabling renaissances in the manufacturing of flexible and printed electronics.

“The first is Plasma3 Atmospheric Plasma Technology, which allows for glow discharge cleaning, surface micro-roughening and activation/functionalization of both rigid and flexible electronics,” Wolf said. “The second is ‘Blow Ion’ Atmospheric Plasma Technology, which can clean, micro-roughen and activate both unpopulated and populated flexible, printed and rigid electronics at zero voltage potential.”

Hoffman said that Martin Automatic has received interest in web handling from PE manufacturers.

“We’ve gained the confidence of the marketplace, and they are coming to us for our expertise in how to transport a web from point A to point B,” Hoffman said. “On the one hand, our customers are running materials that are getting ever thinner and more delicate, and we’re designing and building the automatic roll changers to meet faster and faster processing speeds. On the other end of the spectrum, we have customers who run some incredibly expensive materials at very slow speeds, but they can’t afford tension upsets or stoppages for roll changes. And Martin’s expertise extends both to narrow roll applications and those as wide as 160 in (4 m).”

Growing Interest in Printed Electronics

All of the equipment manufacturers Printed Electronics Now spoke with say they are seeing growth in the PE market.

“The interest is growing, but the market is in a vital stage,” Gebhardt said. “In the past years, innovative demonstrations were realized in laboratories all over the world. The two major challenges right now are to find economically feasible applications for the functionalities, and to establish a stable production for such applications.”

“Even though production has yet to gain serious traction, interest continues to be high, with increasing acceptance that sooner or later it will happen,” Panico concluded.

“Rather than high end products that could disrupt traditional PCB markets, we see tremendous growth potential for ‘simple’ applications by traditional printers,” said Palazzolo. “Over the next 10 years, we will see more and more printers looking to add a little ‘sizzle’ to their mail piece or magazine insert to drive response rates. We also see these customers looking to add functional elements to their portfolio to allow better inventory management by their end users (RFID/NFC). This will be accomplished by adding PE capabilities to their existing production equipment.”

Wolf said that interest in printed electronics is definitely growing, with the OLED lighting and display market heating up for commercial applications in automotive and electronic spaces.

“Printed and flexible sensor technologies are also growing since they offer distinct advantages over non-printed sensors, such as lower cost, and the opportunity to create devices on a wide variety of substrates which can be shaped and individually tailored to roll-to-roll and 3D surface profiles,” Wolf added.

“In our point of view, the PE market is really entering the industrialization step, especially for OPV applications,” Bernardin said. “Ceradrop is working on the inkjet printing production line for the manufacturing of tailor-made organic PV modules in the context of the project called Inkjet OPV and led by DisaSolar. Furthermore, our present feeling on the market is that the production on an industrial scale of components 100% made by printing processes is a goal that will only be achieved in a medium term. Moreover, we strongly believe in the short-term use of hybrid processes, where innovative printing techniques are inserted into existing production lines as complementary processes.”

Hoffman said that interest in printed electronics and related fields is certainly growing, and Martin is starting to see it gain some traction in terms of commercialization.

“The markets and technologies surrounding PE and related industries, including thin film photovoltaics, batteries and RFID, are starting to take off,” Hoffman added. “But in many cases, while there is a lot of ‘neat’ technology being introduced, the market’s demand for it has been slow to develop. I believe the market has to move the technology rather than vice-versa.

“As and when that happens, non-stop roll-to-roll production is going to be essential to bring these ideas to market in a practical and profitable way,” Hoffman said. “The ability to automate the converting process is critical to maintaining consistency and reducing manufacturing costs. Two key components for the success of the PE process are superior quality tension control and automatic splicing for non-stop roll-to-roll processing. I would agree with some market observers, who believe successful and profitable commercialization depends on manufacturing volumes measured not in square feet but in square miles.”

Farnsworth said that interest in PE is clearly growing, and it is a global interest.

“We are working with clients here in the U.S. and North America, as well as all over the rest of the world,” Farnsworth noted. “I can say that our applications engineers are really accruing travel miles as they personally support clients in their research, development, scale-up and production efforts. Implementation of new technologies takes time, though, and we should caution those who are looking to label PE as ‘what’s next.’ Printed electronics has been in use for many years now, and those of us at the forefront of the effort are fortunate enough to be involved in a growth phase of the technology space, with exciting opportunities for new technologies and products. Our clients are being provided the ability to now realize their creative visions for product innovation. We will all benefit.”

Kreis said that the overall interest in PE definitely is growing, but the overall perception in the market has changed considerably over the recent years.

“What is good for this industry is the growing insight that neither a one-serves-all technology nor a binary ‘its either all-print or all-vacuum’ extremist type of view will be the way to go,” Kreis said. “We see a growing understanding that the best solutions may come from production approaches, where different process technologies are orchestrated to play their specific strengths, and in this way to obtain the best possible solution.

“What also changed recently is a deeper understanding in the community, that organic electronics (OE) doesn’t necessarily benefit from offering more attractive cost models only and therefore should predominantly focus on low-cost, but might offer the best growth opportunities if industries identify and utilize the unique benefits that organic electronics can offer,” Kreis added. “In this way, OE could address perceived hurdles with disruptive methods, or, by enabling new technologies, will open new market opportunities nobody had thought about before.”

“One key market is printed antennas, such as for RFID and for communications devices such as cell phones,” Farnsworth noted. “For these applications, the low cost and high performance of our Metalon ICI copper oxide reduction inks is critical, along with our PulseForge photonic curing tools. These applications are appealing because of the volumes of devices that would be needed, driving tool sales as well as material (ink) sales.

“There is also ongoing interest in photovoltaic applications, particularly from groups doing more fundamental materials research,” Farnsworth added. “While the solar markets have been struggling recently, there are still fundamental opportunities to be realized by true low-cost, efficient photovoltaic technologies. An example is a long-term joint effort at the University of Texas and Colorado State University, led by Dr. Brian Korgel, to understand the application of photonic curing to printable CIGS technologies. Other key application opportunities include sensors, for markets such as automotive and garments.”

“Within our product offer for organic thin films, we see two product lines as most interesting for applications in the field of flexible electronics as well,” said Juergen Kreis, director business development at AIXTRON SE. “AIXTRON’s OVPD (Organic Vapor Phase Deposition) addresses the efficient deposition of organic thin films made of organic small molecules, thus predominantly useful for the manufacturing of OLEDs (display and lighting alike) and OPV devices and, due to its disruptive approach, offers some specific advantages compared to the more common vacuum thermal evaporation.

“AIXTRON’s PVPD (Polymer Vapor Phase Deposition) approach, implemented in our PRODOS line, allows the deposition and in-situ formation of polymer-based thin films in an all dry approach, thus offering again some unique possibilities compared to solvent-based polymer deposition processes,” Kreis added. “Both technologies make use of AIXTRON’s CCS (Close Coupled Showerhead) approach, which allows to scale gas phase processes based on well understood scaling rules to any relevant production and substrate size. This approach also addresses the need for efficient material utilization, which, given the considerably high material costs of performance materials, is key for efficient device manufacturing, for instance in the field of OLED lighting.”

Nicolas Bernardin, CeraPrinter product manager for Ceradrop, noted that the key markets that Ceradrop is serving within the flexible and printed electronics field include flexible solar cells (OPV), smart cards, antennas, interconnects and passive components.

Mandy Gebhardt, head of marketing department, 3D-Micromac AG, noted that 3D-Micromac’s key markets are OPV, OLED, RFID, flexible displays and tools for general R&D purposes.

“We have some ideas as to what may become ‘key markets,’ but we’re taking a wide view,” said Bob Hoffman, one of Martin Automatic’s regional managers and its market development specialist for PE. “Martin’s expertise in handling webs – substrates delivered and processed as roll stock – spans a broad range of processes. We’re talking to or working with companies, individuals, research scientists, engineers, academics – you name it – who are involved in just about every printing, coating and converting technology related to photovoltaics, energy storage, and all manner of PE.”

Rory Wolf, vice president, business development and technology director – atmospheric plasma systems at Enercon Industries Corporation, said that Enercon’s participation in the flexible and printed electronics space has primarily been in enabling roll-to-roll manufacturing of thin flexible electronics with atmospheric plasma surface modification technologies.

“By using in-line plasma technologies, manufacturers of printed and flexible electronics have significantly lowered surface cleaning and activation costs,” Wolf said. “The flexible nature of these devices dramatically enables not only their application within a broader range of stationary and remote devices, but also their integration with other flexible materials. A number of breakthroughs have been achieved by leveraging atmospheric pressure plasma technology as an integrated roll-to-roll, continuous production line process for manufacturing flexible electronics materials.”

John Palazzolo, director, marketing and sales, Adphos North America, Inc., said that Adphos specializes in drying and curing inks and coatings in the graphic arts market. “Our primary applications in this area have been drying water-based inkjet ink on direct mail and trans promo billing statements,” Palazzolo noted. “We continue to see interest in ‘smart printing’ applications at these customers expanding from ‘print-to-communicate’ into functional printing – allowing marketers the possibility of higher response rates using PE.”

Helping PE Manufacturers Overcome Challenges

One of the largest hurdles facing PE manufacturers is the ability to mass produce the applications. Xenon Corporation is active throughout the printed electronics field, from R&D for numerous applications to production for displays, and Xenon Corporation CEO Lou Panico said that ink to substrate adhesion, increasing line speed and low temperature solutions have been some of the biggest challenges that Xenon has helped its customers overcome.

Kreis noted that in order to address the ultimate goal of taking flexible and organic electronics to mass production levels, attractive manufacturing costs are key.

“As manufacturing costs must be understood as the total cost of ownership rather than CAPEX or variable costs only, it is essential to plan for production methods, which allow the ability to explore a new idea on small scale, scale it up in a straightforward manner to relevant dimensions without the need for determining all process parameters again for each dimension change, and gain on manufacturing costs with increasing size by increasing material utilization,” Kreis said. “Besides the cost factor only, novel technologies make the most sense if they do not only replicate existing processes, but also introduce novel possibilities or enhanced process features.

“Here, gas phase deposition potentially offers more freedom compared to solvent-based wet chemistry due to its intrinsic purity and potentially excellent ability to form films with highest contour conformity,” Kreis added. “For that reason, we consider OVPD and PVPD as enabling technologies for a wide range of functional thin films, offering efficient manufacturing of known device architectures and potentially opening new opportunities for novel solutions alike.”

“Many potential customers come to us with an initial interest in printed electronics but not necessarily a lot of expertise,” Farnsworth said. “Because of our origins as a materials company, our ink formulation expertise, and our capabilities with the PulseForge photonic curing tools, we often act as technology advisors to our clients. This is far beyond being a simple ink or tool provider. We also work with them in materials selection, be it for our inks or inks from other suppliers, process optimization for print and cure operations, and even in some cases for developing new engineering design guidelines for using printed electronics technologies. It never gets old to see the enthusiasm of a client, or to hear the relief and excitement in their voices, when they realize we can actually get them to their aggressive design and performance targets.”

“One of the biggest challenges was to make inkjet printing easier for printed electronics,” Bernardin said. “Another important point was to propose equipment on the market able to adapt to electronic materials to be deposited as well as to complex components design to be printed. That was only possible because of our bottom-up approach, and more concretely thanks to our exclusive CAD-CAM software CeraSlice.”

Gebhardt said that 3D-Micromac’s equipment helps manufacturers have a controlled process environment, with the flexibility to adjust to changes in the process chain, as well as process control (e.g. automated data logging for later cross reference).

“It is well known that a large barrier to growth of PE has been the cost of materials and substrates,” Palazzolo said. “The price of inks and coatings as well as substrates must come down to make the dream of ‘NFC tags and labels on every product’ or ‘light up postcards in every mailbox’ a reality. The required substrates to meet these cost targets are typically low cost polymer films, especially PET, which are thermally sensitive. Since the drying and curing temperature of these functional inks and coatings are often higher than the deformation temperature of the substrate, exotic curing technologies have historically been required.”

Wolf said that the most significant challenges overcome by the integration of atmospheric plasma technologies includes surface roughness, which is typically not good enough for making transistors, as the roughness average needs to be 2 to 3 angstroms, and plastic substrates are five to 10 times rougher than glass.

“Enercon’s atmospheric plasmas technologies are creating defined surface micro-roughness, improving lamination/encapsulation strength, enabling extremely minute printed feature sizes and improving ink-to-substrate compatibility through surface cleaning and functionalization effects,” Wolf added.

“Many leaders in the field have confirmed to us that maintaining exacting web tensions is an essential requirement to avoid any compromise of the delicate substrate properties or functional characteristics of the ink or coating,” Hoffman said. “These converted materials are very expensive, so process waste has to be minimized. As these technologies take off and become commercialized, we are creating or adapting web handling solutions for them.

“An example is our work with very delicate web structures, including light foils that are subject to wrinkling and creasing,” Hoffman added. “We’re matching production line speeds in successfully unwinding, rewinding and splicing these webs without damage or disruption to the process.”

Recent Equipment Innovations

To meet the needs of printed electronics manufacturers, equipment suppliers are introducing new machines for production as well as research into the market place. For example, Xenon recently announced the release of its new Sinteron 3000, bringing more flexibility and energy per pulse to the metallic ink offering solutions not previously attainable.

“The Sinteron 3000 provides high-energy pulsed light for reliable, repeatable sintering of copper nano particles on heat-sensitive materials such as PET,” Panico said. “The system features a high intensity pulsed lamp that provides a broadband spectrum of light, from 240 nm to 1000 nm, with adjustable pulse energy up to 3300 Joules per pulse and pulse durations up to 4 ms.”

Kreis said that as a result of being a supplier of production equipment, continuous product innovation is an intrinsic building block in AIXTRON’s product strategy across all of its business segments.

“For areas that still see a strong need for research, we do offer dedicated R&D platforms that allow a company to explore a certain approach on a smaller scale, yet always implement a method in a way that processed on such a tool always can be scaled to production levels with straightforward scaling rules,” Kreis said.

In 2012, AIXTRON introduced PVPD processes with PRODOS-200, a modular R&D platform, which, depending on its specific configuration, can be used to investigate a number of different polymer thin films.

“While the basic principle of OVPD already has proven its unique capabilities in a number of projects, for efficient OLED mass manufacturing, efficient evaporation of the organic precursors is of paramount importance,” Kreis noted. “Understanding this, AIXTRON has developed its proprietary STExS (Short Thermal Exposure Source) approach, which addresses high throughput manufacturing by enabling high deposition rates also for very large substrate areas, while at the same time the thermal stress to the precious organic precursors can be considerably reduced in comparison to conventional evaporation processes. Respectively, with STExS, we provide a solution which, on the one hand, helps to reduce production time, and, on the other hand, prevents material decomposition by reducing the thermal load of the materials.”

Farnsworth said that NovaCentrix has two key initiatives that are keeping the company busy right now.

“First, we launched our new low-cost PulseForge tool in December, optimized for R&D efforts but still retaining the pulse shaping capabilities of the full-size PulseForge tools,” Farnsworth said. “Customers have been responding very well to this new product, as it extends our state-of-the-art photonic curing capabilities to a customer segment that was having a hard time accessing our full-size tools.”

NovaCentrix’s second major initiative is its new print service this summer, which is being launched this summer.

“We are installing a full-size print press, based initially on flexographic and screen printing,” Farnsworth noted. “It will be fully equipped with our PulseForge tools. We are making this available for clients who need outsourced pilot production work or even full production efforts. We will be able to produce the number of units per hour or day using this press that might prevent a client from having to invest themselves in the equipment and expertise to do this in-house. This is in response to many of our clients passing the concept and development phases of their product development efforts, but then not having an accessible scale-up resource, either in cost or in timing, to meet their needs. By taking this step ourselves, we are building on the materials, printing and post-processing expertise of our team. Admittedly we are also having to add to our team, so we are moving to a new near-by facility to house both the print press and our growing team, as well as our other material and tool operations, in April.”

Gebhardt said that 3D-Micromac’s most recent innovation is its microFLEX platform, a modular roll-to-roll tool.

“The main advantage of this platform is that the modular approach enables the customer to either reorder the process chain or extend the process chain with additional features,” Gebhardt said. “This can be realized by simply adjusting the components in the working space of the tool, but even more so by readjusting the order of the modules or adding additional modules/functions later on. This way, the customer gets increased investment safety as he can adjust to developments in the future. The design even allows the customer to basically upgrade an R&D tool to a pilot line stage, and later on also to a full production line.”

Bernardin said that Ceradrop’s latest generation of curing modules integrated inline in its inkjet printers offers greater capability for the customer to build directly with Ceradrop’s equipment. In addition, different technologies of inkjet printheads embedded on Ceradrop’s printers as well as its ease of change offer greater flexibility and more materials compatible with its equipment.

Palazzolo said that Adphos has introduced a proven technology to solve the barrier of moving drying and curing from concept to the production process. “We have more than 2,000 installations in graphic arts going back 15 years,” Palazzolo said. “The benefit to our customers is allowing a cost effective growth path from curing 1,000 printed samples on a pilot line to full-scale production at 500 feet per minute on a 20-inch wide commercial web press.”

Wolf said that Enercon has developed two types of technological solutions for enabling renaissances in the manufacturing of flexible and printed electronics.

“The first is Plasma3 Atmospheric Plasma Technology, which allows for glow discharge cleaning, surface micro-roughening and activation/functionalization of both rigid and flexible electronics,” Wolf said. “The second is ‘Blow Ion’ Atmospheric Plasma Technology, which can clean, micro-roughen and activate both unpopulated and populated flexible, printed and rigid electronics at zero voltage potential.”

Hoffman said that Martin Automatic has received interest in web handling from PE manufacturers.

“We’ve gained the confidence of the marketplace, and they are coming to us for our expertise in how to transport a web from point A to point B,” Hoffman said. “On the one hand, our customers are running materials that are getting ever thinner and more delicate, and we’re designing and building the automatic roll changers to meet faster and faster processing speeds. On the other end of the spectrum, we have customers who run some incredibly expensive materials at very slow speeds, but they can’t afford tension upsets or stoppages for roll changes. And Martin’s expertise extends both to narrow roll applications and those as wide as 160 in (4 m).”

Growing Interest in Printed Electronics

All of the equipment manufacturers Printed Electronics Now spoke with say they are seeing growth in the PE market.

“The interest is growing, but the market is in a vital stage,” Gebhardt said. “In the past years, innovative demonstrations were realized in laboratories all over the world. The two major challenges right now are to find economically feasible applications for the functionalities, and to establish a stable production for such applications.”

“Even though production has yet to gain serious traction, interest continues to be high, with increasing acceptance that sooner or later it will happen,” Panico concluded.

“Rather than high end products that could disrupt traditional PCB markets, we see tremendous growth potential for ‘simple’ applications by traditional printers,” said Palazzolo. “Over the next 10 years, we will see more and more printers looking to add a little ‘sizzle’ to their mail piece or magazine insert to drive response rates. We also see these customers looking to add functional elements to their portfolio to allow better inventory management by their end users (RFID/NFC). This will be accomplished by adding PE capabilities to their existing production equipment.”

Wolf said that interest in printed electronics is definitely growing, with the OLED lighting and display market heating up for commercial applications in automotive and electronic spaces.

“Printed and flexible sensor technologies are also growing since they offer distinct advantages over non-printed sensors, such as lower cost, and the opportunity to create devices on a wide variety of substrates which can be shaped and individually tailored to roll-to-roll and 3D surface profiles,” Wolf added.

“In our point of view, the PE market is really entering the industrialization step, especially for OPV applications,” Bernardin said. “Ceradrop is working on the inkjet printing production line for the manufacturing of tailor-made organic PV modules in the context of the project called Inkjet OPV and led by DisaSolar. Furthermore, our present feeling on the market is that the production on an industrial scale of components 100% made by printing processes is a goal that will only be achieved in a medium term. Moreover, we strongly believe in the short-term use of hybrid processes, where innovative printing techniques are inserted into existing production lines as complementary processes.”

Hoffman said that interest in printed electronics and related fields is certainly growing, and Martin is starting to see it gain some traction in terms of commercialization.

“The markets and technologies surrounding PE and related industries, including thin film photovoltaics, batteries and RFID, are starting to take off,” Hoffman added. “But in many cases, while there is a lot of ‘neat’ technology being introduced, the market’s demand for it has been slow to develop. I believe the market has to move the technology rather than vice-versa.

“As and when that happens, non-stop roll-to-roll production is going to be essential to bring these ideas to market in a practical and profitable way,” Hoffman said. “The ability to automate the converting process is critical to maintaining consistency and reducing manufacturing costs. Two key components for the success of the PE process are superior quality tension control and automatic splicing for non-stop roll-to-roll processing. I would agree with some market observers, who believe successful and profitable commercialization depends on manufacturing volumes measured not in square feet but in square miles.”

Farnsworth said that interest in PE is clearly growing, and it is a global interest.

“We are working with clients here in the U.S. and North America, as well as all over the rest of the world,” Farnsworth noted. “I can say that our applications engineers are really accruing travel miles as they personally support clients in their research, development, scale-up and production efforts. Implementation of new technologies takes time, though, and we should caution those who are looking to label PE as ‘what’s next.’ Printed electronics has been in use for many years now, and those of us at the forefront of the effort are fortunate enough to be involved in a growth phase of the technology space, with exciting opportunities for new technologies and products. Our clients are being provided the ability to now realize their creative visions for product innovation. We will all benefit.”

Kreis said that the overall interest in PE definitely is growing, but the overall perception in the market has changed considerably over the recent years.

“What is good for this industry is the growing insight that neither a one-serves-all technology nor a binary ‘its either all-print or all-vacuum’ extremist type of view will be the way to go,” Kreis said. “We see a growing understanding that the best solutions may come from production approaches, where different process technologies are orchestrated to play their specific strengths, and in this way to obtain the best possible solution.

“What also changed recently is a deeper understanding in the community, that organic electronics (OE) doesn’t necessarily benefit from offering more attractive cost models only and therefore should predominantly focus on low-cost, but might offer the best growth opportunities if industries identify and utilize the unique benefits that organic electronics can offer,” Kreis added. “In this way, OE could address perceived hurdles with disruptive methods, or, by enabling new technologies, will open new market opportunities nobody had thought about before.”