David Savastano, Editor11.07.14

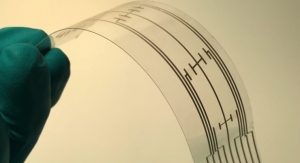

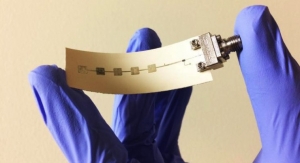

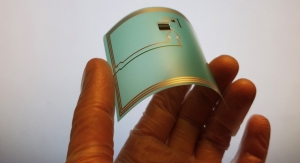

Printed electronics (PE) continues to show growth on a number of fronts. As some applications move from the lab to pilot production and manufacturing, other companies are beginning to think about what flexible and printed electronics can do for their products.

“An increasing number of clients are approaching us, with new interest in printed electronics,” said Stan Farnsworth, vice president of marketing at NovaCentrix. “Technologies have advanced to the point that in most cases off-the-shelf solutions are now available, allowing our clients to move through their product development often-times more quickly than they anticipated.”

“The market is continuing to grow, and we are working on more opportunities,” said Allen Reid, commercial director for NANOGAP.

“The growth opportunities in the flexible and printed electronics markets are clearly apparent,” said Roy Bjorlin, global commercial director, Electronic Materials, Sun Chemical. “A significant amount of our strategic focus at Sun Chemical is in electronic packages or smart packages. Since our alliance with T+ink, we have been exposed to many more applications where advanced materials, including conductive inks, are growing.”

Terry Kaiserman, T+ink co-founder and chief technical officer, said that flexible printed electronics is in a considerable growth surge.

“This surge is attested to by our customer requirements and new inquiries,” said Kaiserman. “The future for flexible conductive compounds and materials will be the norm for industries that require bendable or pliant attributes to their final products.”

“The Toyo Ink Group has seen a growing trend in the use of screenprinting to form electrodes of 100 um or less, primarily for touch panels,” said Kody Osato, marketing manager, Advanced Materials Division at Toyo Ink International Corp. “This has resulted in the wider application of Toyo Ink’s Rexalpha series of conductive silver paste products.”

Matt Ganslaw, vice president of sales for Creative Materials, said that his company specializes in custom formulations for a wide variety of industries.

“Our conductive inks are developed for specific customers, primarily for EMI shielding, medical electrodes, busbars for touch screens, resistor inks for flexible heaters, security and smart card industry, screen, flexo and gravure solar grid inks and adhesives, and touch screens,” Ganslaw said. “Printed memory is also a growing market for us.”

“We remain excited about and committed to the printed electronics industry because we continue to see new opportunities where printed electronics - and the materials used to create them - can create value across several industries and value chains,” said Steven Willoughby, marketing manager for DuPont Microcircuit Materials. “Many of these new applications require collaboration throughout the value chain to ensure that the materials, manufacturing processes, and equipment all work together to deliver the electrical performance ultimately required.”

“During the year, we have seen a lot of interest in our technology from potential clients in the PV, LED, RFID, sensors for medical diagnostic and automotive applications, and PCB, looking to either switch from silver- to copper-based inks or looking to replace conventional PCB with a printed solution using copper ink – primarily in the interests of reducing costs, but with secondary aims of using flexible, low temperature, cheap substrates, making lighter, smaller devices, making throwaway devices, etc.,” said Ian Clark, sales and marketing director at Intrinsiq Materials.

“ECM exploded in 2012 but slowed to normal levels in 2013,” said Steve Toyama of Engineered Conductive Materials (ECM). “We expect and are seeing nice growth again in 2014. We are growing in pressure sensitive inks and in sprayable inks for medical devices.”

Paul Lindquist, business development manager, Methode Electronics, Inc., said that during the past year, there has been a lot of growth and interest in printed electronic applications.

“Methode has spent a significant amount of time focused on finalizing and proving the robustness of the manufacturing process for opportunities that have been in the pipeline for over a year,” said Lindquist. “There was also a lot of interest generated at the printed electronics show, and most of that activity is picking up in the first quarter of 2014.”

Key Markets for Conductive Inks

Flexible and printed electronics have the potential to be utilized in numerous markets. Sensors and labels, touch panels and lighting, RFID and printed memory are just a few of the places where PE can find a home.

For example, Reid noted silver nanofiber inks for transparent conductive films for touch panels are a key end use market. Clark said that in the near term, PV, LED and RFID are interesting markets, while in the longer term, display, touch screen and medical applications offer promise. Farnsworth noted that displays are an excellent field.

“The percentage of our clients working with transparent-conductors and other display-related areas have grown over the past year,” Farnsworth said. “These clients are taking many approaches to the TCO opportunity, both on the materials-innovation side and on the processing side. Packaging is also seeing increased interest. There has been some activity historically in packaging, but the level of activity in that space is really growing.”

“Our strategic focus on applications which include printed antenna RFID and 3D, smart labels, touch switches and sensors, and as part of our collaboration with T+ink, new advanced material packages for applications such as touch code, are exposing Sun Chemical to significant opportunities where a new generation of materials is required,” Bjorlin said.

Toyama said that growth markets include computer input devices, medical devices, biosensors, solar panels, heaters, ESD coating in fabrics and possibly ACF adhesives. “All of the above are in production, except for the pilot testing of ACF adhesives currently going on now,” Toyama added.

Ganslaw said that Creative Materials is seeing growth in medical applications, as well as lighting and touch sensors.

“We are seeing growth, particularly in the medical field in lab testing for medical sensors for glucose or lead, or a patient’s status in an ambulance,” Ganslaw added. “We are also seeing opportunities in lighting with flexible LEDs and with busbars for touch sensors; there’s a lot of growth in those markets. Printed memory is also a growing market for us.”

“At present, the standout market for conductive inks is touch panels,” Osato said.

“Currently we are seeing the most activity in user interface, RFID, display and biosensor applications,” Lindquist said.

Willoughby said that the medical diagnostic market continues to be prominent for conductive inks with new applications starting to emerge.

“Other prominent markets include human interface applications such as traditional membrane touch switches and next-generation touch technologies” said Willoughby. “There are also exciting emerging opportunities in spaces such as antennas and wearable electronics. We expect additional new applications to emerge that will make the idea of ‘electronics everywhere’ become a reality.”

Kaiserman said that T+ink has numerous customer verticals, all of which have different requirements.

“For the T+Mold products, our conductive technology is geared towards rigid automotive, aerospace and white goods products, to name a few,” Kaiserman said. “We typically use high Tg resins and polymers.

“For the Touch Code product, we span a myriad of substrates from rigid glass to knit fabrics, and even to highly elastomeric substrates requiring significant elongation of the conductive materials,” Kaiserman noted. “This can use both low and high Tg constituents to allow for continuity of the printed circuit when subjected to abuse consistent with the particular industry we deliver to. T+ink services the textile market, which requires washable conductors for woven, knit and nonwoven fabrics used for heaters, sensors and switches. T+ink also services the packaging market that can print on paper, board, flexible substrates such as HDPE, LDPE, PVC, etc., or more rigid plastics used for a blister pack and product packaging.”

Heading to Commercialization

For flexible and printed electronics to begin to reach their potential, products have to reach the marketplace. While some applications have had commercial success - printed medical sensors and displays come to mind – other applications have yet to come to market. Conductive ink manufacturers are in an ideal position to see where their customers are heading, and the good news is that more PE products are reaching pilot production and manufacturing.

“We are certainly seeing more printed electronics applications reaching the pilot production and manufacturing stages,” said Bjorlin. “In particular, we are seeing the advanced designs moving towards production at a faster rate. This includes applications for nano silver and inkjet.”

“We are supplying nanofiber and nanoparticle dispersions, which are both being used at pilot production and manufacturing stages,” Reid said.

Once more PE products like temperature sensors reach the market, it is likely other companies will see the advantages and will follow.

“Intrinsiq is at or near pilot production stage with several clients,” Clark said. “As the first application goes commercial, we anticipate a domino effect.”

“As always, there is a continuum, and various applications are at various stages in their life cycles” said Willoughby. “However the general trend we see is that more applications are moving toward commercialization. We continue to see the opportunity to speed adoption through increased collaboration along the supply chain.”

“It has been a challenging process with a lot of auxiliary issues which needed to be addressed. However, the applications are now proceeding to pilot and small production volumes,” Lindquist said.

“We have seen an increase in cases where transparent conductive films are produced by the wet-coating process,” Osato said.

Kaiserman said that there is a tremendous amount of research stage and development stage projects within T+ink, and quite a few have emerged as manufacturing orders.

“Because T+ink has been in business in its different forms for so many years, we have mature and tested formulations that allow most every customer to design a project with existing chemical and engineering know-how,” Kaiserman added.

“For some time, the public discussion of printed electronics has been oriented to product and device performance,” Farnsworth said. “Increasingly though, our clients include people with an operations focus in their job description, with a focus on topics like cost of consumables, product stability and process sensitivity. These customers require products that get the right results reliably and consistently. As more PE companies work with clients in these stages of product use, we’ll see an evolution in the language used to describe the products.”

Important Advances In Conductive Materials

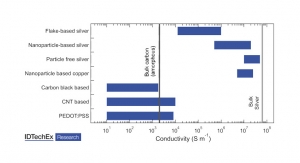

Conductive inks have come a long way in recent years, as suppliers work on meeting the needs of end users. There is still room for improvement, particularly as applications reach production.

“Speed and process simplifications are the key focus areas sought by flexible and printed electronics manufacturers,” said Bjorlin. “Sun Chemical’s range of electronic materials supports both additive and subtractive processes, in addition to aerosol dispensing and inkjet, gravure and offset printing.”

“For nanofibers and transparent conductive films, the drive is to keep improving optical properties, in particular to reduce haze,” Reid said. “For successful commercialization of nanoparticle based inks, low temperature sintering is key.”

Farnsworth and Clark said that conductivity, adhesion and cost are key attributes end users are seeking.

“Clients are still seeking products that maximize performance such as conductivity and substrate adhesion, while minimizing costs,” Farnsworth said. “Progress with end-use applications moving to commercialization is being made because the level of offerings to meet these requirements is improving.”

“The key requirement is delivering high performance, in terms of conductivity and adhesion to substrate, etc. reliably and repeatedly at low cost,” Clark said. “Depending on the demands of the particular application, this tends to require optimization and sometimes reformulation on a case-by-case basis.”

“Cost versus performance is always the equation,” Kaiserman said. “On the material side, lower cost conductors are critical for those of us who want PE to become ubiquitous. On the processing side, lower temperature cure and/or faster cure systems, along with improved stability, are necessary to increase performance and productivity for printers.”

Willoughby reported that DuPont is seeing a few trends from manufacturers.”

“These include the ability to function with new and novel application technologies, getting the right electrical and signal performance for each specific application and the desire to reduce the dependence on precious metals such as silver,” Willoughby added.

Ganslaw noted that increasing conductivity impacts cost.

“Printed electronics manufacturers are seeking a number of advances, such as printing finer features for busbars, touch screens and printed memory, as thinner features means less silver being used,” Ganslaw said. “There is also more tailoring to the conductivity needs for specific areas to reduce cost. Customers are also looking for environmental aging and reliability testing, and we have brought in new testing equipment to meet their needs.”

“There have been advancements in processing efficiency in which the conductive material can be applied only to a required area,” Osato said. “In addition, screen printing as the application method has become simplified and easier to use.”

“Most of the advancements are focused on obtaining adhesion and low resistance levels on substrates which are sensitive to higher temperatures,” Lindquist said. “In addition to the required electrical and physical properties, there is also a need to make connections to the conductive inks, which can be difficult on temperature sensitive substrates. Ink flexibility is another desirable characteristic which would expand the reach of additive manufacturing beyond that of traditional electronics.”

Toyama said that the ability to work with customers on their applications is essential.

“Everyone thinks they need 10-15 micron silver lines, but the real growth occurs with solving problems with the new ideas inventors are coming up with,” Toyama said. “Ink companies have to be innovative and willing to solve hard problems to grow this business moving forward. Finer lines are only a small portion for future growth. Invention is where ECM is making money.”

New Products

With customers looking for improved performance from their conductive materials, ink suppliers are actively developing new formulations.

“We are working on some new ink formulations,” \Farnsworth said.

“We are involved in a number of custom product development projects with key collaborators,” Reid said.

“T+ink has made acquisitions this past year, and a lot of new products are in the market,” Kaiserman said. “Other products will launch this year and next.”

Lindquist noted that Methode is always working on different product innovations, although it is too early to mention any specific items. “Most of the work in the past year has been focused on expanding the range of substrates,” Lindquist noted.

“We have developed aesthetically pleasing color and opaque conductive inks, a low temperature conductive silicon adhesive used for highly flexible applications, and conductive inks for in-mould decorating,” Ganslaw said.

“This last year we introduced our LAPS-60 laser precision sintering system with full x,y automation, designed for use with our copper inks, for prototype and pre-production work,” Clark said. “These have been selling well to corporate R&D departments and academia. Later this year, we plan to release a production version, which will be designed to fit into new and existing client production lines, including roll-to-roll.”

Osato reported that the Toyo Ink Group succeeded in reproducing patterns of around 30 um with conductive silver pastes suited to laser-ablation processing.

“In some applications, manufacturers are paying for more conductivity than they need, and therefore, more silver,” said Willoughby. “We recently launched our PE 8xx series of conductors to offer an alternative with less silver and the right amount of conductivity for certain applications. This series offers a solid value today – with silver at $20 – and a great value in the future when silver prices may be higher. These products include DuPont PE825 and PE826 for MTS applications; DuPont PE815 for RFID applications to help drive improved radio frequency performance; and DuPont PE871 for wearable electronics applications.”

“We have partnered with Sensitronics to produce their pressure sensitive inks and films,” Toyama said. “These inks were responsible for our biggest sales in the past couple years and moving forward.. Also anisotropic conductive adhesives with an innovative twist look promising for new markets we were just made aware of.”

Outlook for Flexible and Printed Electronics

With more end users heading to pilot production and manufacturing, conductive ink suppliers are optimistic about the opportunities ahead for flexible and printed electronics.

“I expect the trends we are seeing to continue,” Farnsworth said. “I expect more early explorers to the space, more organizations committing to research and development of PE-related technologies and products, and, importantly, more organizations transitioning those products into manufacturing. This is our experience at NovaCentrix and, judging by what I see at conferences and read in the press, also the experiences of many other companies in the PE space.”

“The outlook remains very bright for printed electronics,” said Bjorlin. “For Sun Chemical, the effort to support a full range of strategic applications has exposed us to many new growth opportunities. This has enabled our research teams to focus on developing new materials to support these emerging applications.”

“The outlook is very positive, with high confidence in strong market growth though the supply chain,” Reid said.

“For any application, small lot and large variety production of electronic devices is becoming the trend,” Osato said. “We believe that cases that use the simple process of printing method together with conductive pastes as the composite material will expand on a global scale.”

“In the near and medium term, projects are moving into pilot plant and manufacturing,” Lindquist said. “Since the technology is not a drop in replacement, customers are still going through the process of confirming the market acceptance of the new technology.”

Ganslaw expects the printed electronics industry to make significant strides toward commercialization.

“I do see for the next five to 10 years a big push going to the market and becoming a significant industry,” Ganslaw noted.

“We are very bullish – we continue to pick up new clients, as well as maintaining our long-term collaborative relationships with major clients with whom we are working to integrate our ink technology into their next generation device manufacture,” said Clark.

“We have a base of new markets and customers that will make 2014 and beyond look promising for nice growth with decent margins,” Toyama said. “New products command higher margins so we are focused on these new markets.”

“We are cautiously optimistic for near-term growth but see further potential for future growth as new applications are pursued and emerging technologies mature,” Willoughby said.

“We are in for the ride of our lives,” Kaiserman said. “Momentum is growing rapidly and many of us in the PE field are finally at the right place at the right time.”

“An increasing number of clients are approaching us, with new interest in printed electronics,” said Stan Farnsworth, vice president of marketing at NovaCentrix. “Technologies have advanced to the point that in most cases off-the-shelf solutions are now available, allowing our clients to move through their product development often-times more quickly than they anticipated.”

“The market is continuing to grow, and we are working on more opportunities,” said Allen Reid, commercial director for NANOGAP.

“The growth opportunities in the flexible and printed electronics markets are clearly apparent,” said Roy Bjorlin, global commercial director, Electronic Materials, Sun Chemical. “A significant amount of our strategic focus at Sun Chemical is in electronic packages or smart packages. Since our alliance with T+ink, we have been exposed to many more applications where advanced materials, including conductive inks, are growing.”

Terry Kaiserman, T+ink co-founder and chief technical officer, said that flexible printed electronics is in a considerable growth surge.

“This surge is attested to by our customer requirements and new inquiries,” said Kaiserman. “The future for flexible conductive compounds and materials will be the norm for industries that require bendable or pliant attributes to their final products.”

“The Toyo Ink Group has seen a growing trend in the use of screenprinting to form electrodes of 100 um or less, primarily for touch panels,” said Kody Osato, marketing manager, Advanced Materials Division at Toyo Ink International Corp. “This has resulted in the wider application of Toyo Ink’s Rexalpha series of conductive silver paste products.”

Matt Ganslaw, vice president of sales for Creative Materials, said that his company specializes in custom formulations for a wide variety of industries.

“Our conductive inks are developed for specific customers, primarily for EMI shielding, medical electrodes, busbars for touch screens, resistor inks for flexible heaters, security and smart card industry, screen, flexo and gravure solar grid inks and adhesives, and touch screens,” Ganslaw said. “Printed memory is also a growing market for us.”

“We remain excited about and committed to the printed electronics industry because we continue to see new opportunities where printed electronics - and the materials used to create them - can create value across several industries and value chains,” said Steven Willoughby, marketing manager for DuPont Microcircuit Materials. “Many of these new applications require collaboration throughout the value chain to ensure that the materials, manufacturing processes, and equipment all work together to deliver the electrical performance ultimately required.”

“During the year, we have seen a lot of interest in our technology from potential clients in the PV, LED, RFID, sensors for medical diagnostic and automotive applications, and PCB, looking to either switch from silver- to copper-based inks or looking to replace conventional PCB with a printed solution using copper ink – primarily in the interests of reducing costs, but with secondary aims of using flexible, low temperature, cheap substrates, making lighter, smaller devices, making throwaway devices, etc.,” said Ian Clark, sales and marketing director at Intrinsiq Materials.

“ECM exploded in 2012 but slowed to normal levels in 2013,” said Steve Toyama of Engineered Conductive Materials (ECM). “We expect and are seeing nice growth again in 2014. We are growing in pressure sensitive inks and in sprayable inks for medical devices.”

Paul Lindquist, business development manager, Methode Electronics, Inc., said that during the past year, there has been a lot of growth and interest in printed electronic applications.

“Methode has spent a significant amount of time focused on finalizing and proving the robustness of the manufacturing process for opportunities that have been in the pipeline for over a year,” said Lindquist. “There was also a lot of interest generated at the printed electronics show, and most of that activity is picking up in the first quarter of 2014.”

Key Markets for Conductive Inks

Flexible and printed electronics have the potential to be utilized in numerous markets. Sensors and labels, touch panels and lighting, RFID and printed memory are just a few of the places where PE can find a home.

For example, Reid noted silver nanofiber inks for transparent conductive films for touch panels are a key end use market. Clark said that in the near term, PV, LED and RFID are interesting markets, while in the longer term, display, touch screen and medical applications offer promise. Farnsworth noted that displays are an excellent field.

“The percentage of our clients working with transparent-conductors and other display-related areas have grown over the past year,” Farnsworth said. “These clients are taking many approaches to the TCO opportunity, both on the materials-innovation side and on the processing side. Packaging is also seeing increased interest. There has been some activity historically in packaging, but the level of activity in that space is really growing.”

“Our strategic focus on applications which include printed antenna RFID and 3D, smart labels, touch switches and sensors, and as part of our collaboration with T+ink, new advanced material packages for applications such as touch code, are exposing Sun Chemical to significant opportunities where a new generation of materials is required,” Bjorlin said.

Toyama said that growth markets include computer input devices, medical devices, biosensors, solar panels, heaters, ESD coating in fabrics and possibly ACF adhesives. “All of the above are in production, except for the pilot testing of ACF adhesives currently going on now,” Toyama added.

Ganslaw said that Creative Materials is seeing growth in medical applications, as well as lighting and touch sensors.

“We are seeing growth, particularly in the medical field in lab testing for medical sensors for glucose or lead, or a patient’s status in an ambulance,” Ganslaw added. “We are also seeing opportunities in lighting with flexible LEDs and with busbars for touch sensors; there’s a lot of growth in those markets. Printed memory is also a growing market for us.”

“At present, the standout market for conductive inks is touch panels,” Osato said.

“Currently we are seeing the most activity in user interface, RFID, display and biosensor applications,” Lindquist said.

Willoughby said that the medical diagnostic market continues to be prominent for conductive inks with new applications starting to emerge.

“Other prominent markets include human interface applications such as traditional membrane touch switches and next-generation touch technologies” said Willoughby. “There are also exciting emerging opportunities in spaces such as antennas and wearable electronics. We expect additional new applications to emerge that will make the idea of ‘electronics everywhere’ become a reality.”

Kaiserman said that T+ink has numerous customer verticals, all of which have different requirements.

“For the T+Mold products, our conductive technology is geared towards rigid automotive, aerospace and white goods products, to name a few,” Kaiserman said. “We typically use high Tg resins and polymers.

“For the Touch Code product, we span a myriad of substrates from rigid glass to knit fabrics, and even to highly elastomeric substrates requiring significant elongation of the conductive materials,” Kaiserman noted. “This can use both low and high Tg constituents to allow for continuity of the printed circuit when subjected to abuse consistent with the particular industry we deliver to. T+ink services the textile market, which requires washable conductors for woven, knit and nonwoven fabrics used for heaters, sensors and switches. T+ink also services the packaging market that can print on paper, board, flexible substrates such as HDPE, LDPE, PVC, etc., or more rigid plastics used for a blister pack and product packaging.”

Heading to Commercialization

For flexible and printed electronics to begin to reach their potential, products have to reach the marketplace. While some applications have had commercial success - printed medical sensors and displays come to mind – other applications have yet to come to market. Conductive ink manufacturers are in an ideal position to see where their customers are heading, and the good news is that more PE products are reaching pilot production and manufacturing.

“We are certainly seeing more printed electronics applications reaching the pilot production and manufacturing stages,” said Bjorlin. “In particular, we are seeing the advanced designs moving towards production at a faster rate. This includes applications for nano silver and inkjet.”

“We are supplying nanofiber and nanoparticle dispersions, which are both being used at pilot production and manufacturing stages,” Reid said.

Once more PE products like temperature sensors reach the market, it is likely other companies will see the advantages and will follow.

“Intrinsiq is at or near pilot production stage with several clients,” Clark said. “As the first application goes commercial, we anticipate a domino effect.”

“As always, there is a continuum, and various applications are at various stages in their life cycles” said Willoughby. “However the general trend we see is that more applications are moving toward commercialization. We continue to see the opportunity to speed adoption through increased collaboration along the supply chain.”

“It has been a challenging process with a lot of auxiliary issues which needed to be addressed. However, the applications are now proceeding to pilot and small production volumes,” Lindquist said.

“We have seen an increase in cases where transparent conductive films are produced by the wet-coating process,” Osato said.

Kaiserman said that there is a tremendous amount of research stage and development stage projects within T+ink, and quite a few have emerged as manufacturing orders.

“Because T+ink has been in business in its different forms for so many years, we have mature and tested formulations that allow most every customer to design a project with existing chemical and engineering know-how,” Kaiserman added.

“For some time, the public discussion of printed electronics has been oriented to product and device performance,” Farnsworth said. “Increasingly though, our clients include people with an operations focus in their job description, with a focus on topics like cost of consumables, product stability and process sensitivity. These customers require products that get the right results reliably and consistently. As more PE companies work with clients in these stages of product use, we’ll see an evolution in the language used to describe the products.”

Important Advances In Conductive Materials

Conductive inks have come a long way in recent years, as suppliers work on meeting the needs of end users. There is still room for improvement, particularly as applications reach production.

“Speed and process simplifications are the key focus areas sought by flexible and printed electronics manufacturers,” said Bjorlin. “Sun Chemical’s range of electronic materials supports both additive and subtractive processes, in addition to aerosol dispensing and inkjet, gravure and offset printing.”

“For nanofibers and transparent conductive films, the drive is to keep improving optical properties, in particular to reduce haze,” Reid said. “For successful commercialization of nanoparticle based inks, low temperature sintering is key.”

Farnsworth and Clark said that conductivity, adhesion and cost are key attributes end users are seeking.

“Clients are still seeking products that maximize performance such as conductivity and substrate adhesion, while minimizing costs,” Farnsworth said. “Progress with end-use applications moving to commercialization is being made because the level of offerings to meet these requirements is improving.”

“The key requirement is delivering high performance, in terms of conductivity and adhesion to substrate, etc. reliably and repeatedly at low cost,” Clark said. “Depending on the demands of the particular application, this tends to require optimization and sometimes reformulation on a case-by-case basis.”

“Cost versus performance is always the equation,” Kaiserman said. “On the material side, lower cost conductors are critical for those of us who want PE to become ubiquitous. On the processing side, lower temperature cure and/or faster cure systems, along with improved stability, are necessary to increase performance and productivity for printers.”

Willoughby reported that DuPont is seeing a few trends from manufacturers.”

“These include the ability to function with new and novel application technologies, getting the right electrical and signal performance for each specific application and the desire to reduce the dependence on precious metals such as silver,” Willoughby added.

Ganslaw noted that increasing conductivity impacts cost.

“Printed electronics manufacturers are seeking a number of advances, such as printing finer features for busbars, touch screens and printed memory, as thinner features means less silver being used,” Ganslaw said. “There is also more tailoring to the conductivity needs for specific areas to reduce cost. Customers are also looking for environmental aging and reliability testing, and we have brought in new testing equipment to meet their needs.”

“There have been advancements in processing efficiency in which the conductive material can be applied only to a required area,” Osato said. “In addition, screen printing as the application method has become simplified and easier to use.”

“Most of the advancements are focused on obtaining adhesion and low resistance levels on substrates which are sensitive to higher temperatures,” Lindquist said. “In addition to the required electrical and physical properties, there is also a need to make connections to the conductive inks, which can be difficult on temperature sensitive substrates. Ink flexibility is another desirable characteristic which would expand the reach of additive manufacturing beyond that of traditional electronics.”

Toyama said that the ability to work with customers on their applications is essential.

“Everyone thinks they need 10-15 micron silver lines, but the real growth occurs with solving problems with the new ideas inventors are coming up with,” Toyama said. “Ink companies have to be innovative and willing to solve hard problems to grow this business moving forward. Finer lines are only a small portion for future growth. Invention is where ECM is making money.”

New Products

With customers looking for improved performance from their conductive materials, ink suppliers are actively developing new formulations.

“We are working on some new ink formulations,” \Farnsworth said.

“We are involved in a number of custom product development projects with key collaborators,” Reid said.

“T+ink has made acquisitions this past year, and a lot of new products are in the market,” Kaiserman said. “Other products will launch this year and next.”

Lindquist noted that Methode is always working on different product innovations, although it is too early to mention any specific items. “Most of the work in the past year has been focused on expanding the range of substrates,” Lindquist noted.

“We have developed aesthetically pleasing color and opaque conductive inks, a low temperature conductive silicon adhesive used for highly flexible applications, and conductive inks for in-mould decorating,” Ganslaw said.

“This last year we introduced our LAPS-60 laser precision sintering system with full x,y automation, designed for use with our copper inks, for prototype and pre-production work,” Clark said. “These have been selling well to corporate R&D departments and academia. Later this year, we plan to release a production version, which will be designed to fit into new and existing client production lines, including roll-to-roll.”

Osato reported that the Toyo Ink Group succeeded in reproducing patterns of around 30 um with conductive silver pastes suited to laser-ablation processing.

“In some applications, manufacturers are paying for more conductivity than they need, and therefore, more silver,” said Willoughby. “We recently launched our PE 8xx series of conductors to offer an alternative with less silver and the right amount of conductivity for certain applications. This series offers a solid value today – with silver at $20 – and a great value in the future when silver prices may be higher. These products include DuPont PE825 and PE826 for MTS applications; DuPont PE815 for RFID applications to help drive improved radio frequency performance; and DuPont PE871 for wearable electronics applications.”

“We have partnered with Sensitronics to produce their pressure sensitive inks and films,” Toyama said. “These inks were responsible for our biggest sales in the past couple years and moving forward.. Also anisotropic conductive adhesives with an innovative twist look promising for new markets we were just made aware of.”

Outlook for Flexible and Printed Electronics

With more end users heading to pilot production and manufacturing, conductive ink suppliers are optimistic about the opportunities ahead for flexible and printed electronics.

“I expect the trends we are seeing to continue,” Farnsworth said. “I expect more early explorers to the space, more organizations committing to research and development of PE-related technologies and products, and, importantly, more organizations transitioning those products into manufacturing. This is our experience at NovaCentrix and, judging by what I see at conferences and read in the press, also the experiences of many other companies in the PE space.”

“The outlook remains very bright for printed electronics,” said Bjorlin. “For Sun Chemical, the effort to support a full range of strategic applications has exposed us to many new growth opportunities. This has enabled our research teams to focus on developing new materials to support these emerging applications.”

“The outlook is very positive, with high confidence in strong market growth though the supply chain,” Reid said.

“For any application, small lot and large variety production of electronic devices is becoming the trend,” Osato said. “We believe that cases that use the simple process of printing method together with conductive pastes as the composite material will expand on a global scale.”

“In the near and medium term, projects are moving into pilot plant and manufacturing,” Lindquist said. “Since the technology is not a drop in replacement, customers are still going through the process of confirming the market acceptance of the new technology.”

Ganslaw expects the printed electronics industry to make significant strides toward commercialization.

“I do see for the next five to 10 years a big push going to the market and becoming a significant industry,” Ganslaw noted.

“We are very bullish – we continue to pick up new clients, as well as maintaining our long-term collaborative relationships with major clients with whom we are working to integrate our ink technology into their next generation device manufacture,” said Clark.

“We have a base of new markets and customers that will make 2014 and beyond look promising for nice growth with decent margins,” Toyama said. “New products command higher margins so we are focused on these new markets.”

“We are cautiously optimistic for near-term growth but see further potential for future growth as new applications are pursued and emerging technologies mature,” Willoughby said.

“We are in for the ride of our lives,” Kaiserman said. “Momentum is growing rapidly and many of us in the PE field are finally at the right place at the right time.”