David Savastano, Editor03.09.18

As the world tuned into the opening ceremonies of the 2018 Winter Olympic Games in South Korea, viewers saw the US athletes in red, white and blue parkas designed by Ralph Lauren.

What they didn’t know was that silver also played a role, in this case conductive silver and carbon inks used for printed electronics heaters designed by Butler Technologies (BTI) to keep the athletes warm in the frigid outdoors.

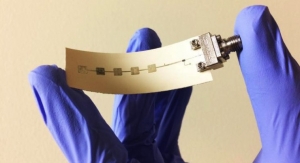

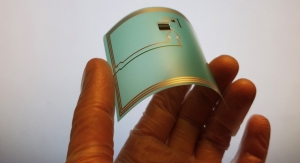

How large is the market for flexible, hybrid and printed electronics systems, which can appear in anything from sensors and wearables to displays and lighting and more? This is uncertain. What is clear is that these systems are appearing in many commercial applications.

General Electric (GE) uses Optomec’s Aerosol Jet technology to print passive strain sensors made of a ceramic material directly onto the turbine blades, saving the company millions of dollars in unnecessary replacements and service. L’Oreal’s My UV Patch, a stretchable skin sensor that monitors UV absorption that L’Oreal developed in conjunction with La Roche-Posay, L’Oreal’s skin care brand, and MC10 Inc., has sold more than one million patches since the heart-shaped patch was introduced in January 2016.

For its Med-ic Syringe Pack, Information Mediary Corp. uses NFC to connect a temperature monitored smart package with printed electronic traces, which records real-time information for each syringe, providing data on whether a patient is actually using the medication. The company reports more than a million units sold to date.

Where the Technology Has Come From

Much has changed in the last 10 years. Wolfgang Mildner, the head of MSWtech, has seen an evolution in the field over the last decade, with the idea that combining printed and silicon-based processes have unique benefits.

“I have seen a change from a research oriented, technically focused market (which was actually no market yet) with a lot of visions,” Mildner said. “I remember statements like “everything will be printed, from solar cells to RFID, from displays to lighting to smart objects. Today, we know its good to print something and for the rest we do hybrid integration.”

Klaus Hecker, executive director of the OE-A, noted that the flexible and printed electronics market had grown substantially over the last decade.

“Ten years ago, besides OLED displays, it was expected that printed RFID will have a breakthrough and enable item level tagging,” Hecker continued. “We have seen that for various reasons this has been more complicated than expected. But recently the availability of a NFC reader infrastructure with basically every smart phone gives a big boost for printed NFC labels, new products and applications.”

Jason Marsh, director of technology for NextFlex, said that in recent years, flexible hybrid systems have evolved.

“Years ago, everybody was focused on printing silicon-free, very low-cost applications, and it was hard to invest capital in markets with such narrow margins,” Marsh added. “Placing semiconductor elements into these systems gives us more intelligent applications with higher margin opportunities.”

Dominic Miranda, regional account manager for Brewer Science, recalled that a decade ago, the printed electronics industry was preparing to embark on a new era of growth and prosperity with OLED displays and organic photovoltaics (OPVs) leading the way.

“While much of the market potential of those applications was never fully realized, and some of the applications have faded away completely, the fundamental strengths of printed electronics have not changed,” Miranda added. “Displays will continue to be a very strong market for printed electronics, as evidenced in the rapid development and adoption of OLED.

“In retail and packaging, RFID technologies are expanding and becoming more diverse in and of themselves, with more complex and fully integrated devices,” added Miranda. “Consumer electronics, especially in the wearables space, represent a great fit for flexible sensor technologies. Most significantly, the Internet of Things (IoT) has opened the floodgates of potential technologies and applications, particularly for sensors and integrated or hybrid system solutions (flexible hybrid electronics – FHEs) by enabling affordable, ubiquitous sensing for every existing technology.”

Dr. Janos Veres, program manager, novel and printed electronics, Electronic Materials and Devices Laboratory at the Palo Alto Research Center, Inc. (PARC), said that a little more than 10 years ago, printed displays, printed solar and even fully printed RFID were the promise.

“They represented existing markets that were well understood,” Dr. Veres continued. “Significant investments were made in both by large companies as well as startups. These directions did not take off, mostly because they were against incumbent technologies that found their ways to scale and reduce cost in a conventional way. OLED certainly has design appeal and automotive projects are ongoing.

“Over the last 10 years we saw companies focus on simple printed features, such as sensors, traces for heaters and keyboards, interface panels,” Dr. Veres reported. “Glucose test strips remained the number one segment in fully printed devices. Automotive companies began experimenting with in-mold electronics.

“The most important shift that occurred over this time is that we realized that we should not try to beat silicon; in fact, we should use it as part of our toolkit,” Dr. Veres noted. “Printing then becomes an integration technique to deliver unique form factors, integration of soft and hard materials/components, enabling customized, on-demand products at low cost.”

“Applications for OPV, OLED, RFID and compact printed electronic systems are increasing. The strongest markets are organic PV, labels with NFC function and OLED technology for lighting,” said Andrea Glawe of KROENERT GmbH.

“It appears membrane switches, the original printed electronic product, has become very much of commodity, while other printed technologies like printed antennas, printed sensors and medical wearable patches have gained in applications and acceptance,” said Tom Bianchi, VP of Eastprint.

Wearables are an area that Mildner sees as an opportunity for flexible electronics.

“Consumers recognize that wearables today are not wearable - they are thick, inflexible and heavy,” Mildner observed. “Using combinations of silicon and printed electronics will allow more convenient wearables, which consumers will like.”

“The strongest potential FHE growth markets are medical applications in human health and performance monitoring, such as perspiration chemistry for athletes,” Marsh said. “There are opportunities for positive returns on investment in this space. Flexibility and stretchability of flexible hybrid electronics lend to being worn on the human body, as well as on objects such as bridges, pipelines, airplane wings and more. Advanced RFID systems can provide temperature and humidity readings, and now we can monitor strain as well.”

“In-mold electronics in automotive is already gaining traction,” Dr. Veres said. “The same is true for control panels for appliances. The use of new materials and freedom of design is exciting for manufacturers. Smart packaging is emerging; one can see numerous experiments with NFC. This is driven by the need for brands to differentiate and connect more with their customers. Supply chain efficiency is another driver. Wearables are another area where printed sensors, traces and microchips come together in soft, flexible form factors.”

The Future for the Technology

Industry leaders anticipate much more ahead for flexible, hybrid and printed electronics.

Mike O’Reilly, director, Aerosol Jet product management for Optomec, Inc., said he believes that emerging PE technologies will become mainstream manufacturing solutions.

“Packaging will only get smaller and lighter with customization becoming the norm,” O’Reilly said. “Having the flexibility of dynamic digitally driven manufacturing processes will be must haves for leading EMS companies. Significant next-generation PE solutions growth can be expected over the next 10 years.”

Roy Bjorlin, global commercial and strategic initiatives director at Sun Chemical Advanced Materials, said that the future is bright for intelligent inks and electronic packaging.

“Sun Chemical is confident that advancements in material technology will continue to drive the development of new applications, particularly in the flexible printing space,” Bjorlin observed. “Cost drivers in photovoltaics, consumer interest in wearables and smart packaging and new cost-effective displays and lighting will increase demand for new materials and processes.”

Allen Reid, commercial director for NANOGAP, believes that a decade from now, wearables and low cost printed electronics will be commonplace.

“Flexible displays will be on the market in significant numbers,” Reid continued. “Technical drivers will focus on flexibility and durability, as well reducing cost while improving performance. And as costs come down, don’t be surprised to see the development of new, disruptive technologies with these materials.”

“The flexible and printed electronics industry, a decade from now, would be a world where fully printed electronic systems are an integral part of our daily lives,” said Miranda. “Clothing and wearable devices will be seamlessly connecting us unobtrusively (literally and figuratively) in our work and play.”

“Flexible hybrid electronics are ideal for being integrated into devices for a multitude of applications,” said Marsh. “Wearables can give updates on medical conditions continuously and in real time.

And while we have better diagnostics on automobiles than we have on ourselves in 2018, the converse can become true, with continuous medical monitoring made possible and practical through FHE.”

Dr. Veres observed that printing is significant as it enables on-demand fabrication of such systems on much larger areas.

“It also enables complex integration layer by layer,” Veres added. “This means that printing has the potential to become a valuable manufacturing technique for a multitude of electronics devices. Overall, we envisage a printed FHE future taking us closer to create custom solutions to things small or large, embedding intelligence in the fabric of devices around us.”

For Glawe, one major possibility is seeing all glass building facades equipped with organic photovoltaics. He also believes that NFC will change the way we communicate with products.

“The whole product world is communicating with labels with NFC function,” Glawe continued. “Due to functional labels and equipment which can read the labels, our commercial life will totally change. Your mobile phone will communicate with your refrigerator at home and will get information about the food you need to shop for the dinner in the evening. The machine is communicating with the operator in a way that can communicate equipment failure before it will be happen. Innovative sensor systems will be developed in the future to allow all these communications.”

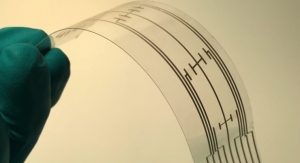

The advantages of the technology – the flexibility, the stretchability, the form factor – are important benefits to designers.

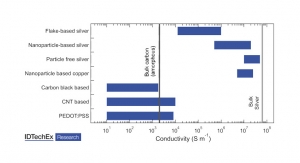

IDTechEx CEO Raghu Das sees the advantages of flexible electronics helping drive future growth.

“The world is moving from hard rigid ‘boxes of electronics’ to softer electronics – electronics that can be curved, be flexed and even stretch, in many guises such as displays, sensors and antennas,” Das continued. “Printed electronics and enabling materials will play a key role in this.”

Stan Farnsworth, chief marketing officer, NovaCentrix, said that he foresees a future where just about everything contains flexible hybrid electronic systems.

“A decade from now, I think most every product we own will incorporate some sort of hybrid printed electronic,” Farnsworth added. “From my discussions with product designers and with my own observations, I believe there will continue to be an evolution in the expectation consumers have regarding the integration of electronics into every-day items. Much of the world is curved, or flexible/dynamic, or both. Electronics designs will adapt to conform with these physical norms which surround us, in the natural world and in the man-made world.”

What they didn’t know was that silver also played a role, in this case conductive silver and carbon inks used for printed electronics heaters designed by Butler Technologies (BTI) to keep the athletes warm in the frigid outdoors.

How large is the market for flexible, hybrid and printed electronics systems, which can appear in anything from sensors and wearables to displays and lighting and more? This is uncertain. What is clear is that these systems are appearing in many commercial applications.

General Electric (GE) uses Optomec’s Aerosol Jet technology to print passive strain sensors made of a ceramic material directly onto the turbine blades, saving the company millions of dollars in unnecessary replacements and service. L’Oreal’s My UV Patch, a stretchable skin sensor that monitors UV absorption that L’Oreal developed in conjunction with La Roche-Posay, L’Oreal’s skin care brand, and MC10 Inc., has sold more than one million patches since the heart-shaped patch was introduced in January 2016.

For its Med-ic Syringe Pack, Information Mediary Corp. uses NFC to connect a temperature monitored smart package with printed electronic traces, which records real-time information for each syringe, providing data on whether a patient is actually using the medication. The company reports more than a million units sold to date.

Where the Technology Has Come From

Much has changed in the last 10 years. Wolfgang Mildner, the head of MSWtech, has seen an evolution in the field over the last decade, with the idea that combining printed and silicon-based processes have unique benefits.

“I have seen a change from a research oriented, technically focused market (which was actually no market yet) with a lot of visions,” Mildner said. “I remember statements like “everything will be printed, from solar cells to RFID, from displays to lighting to smart objects. Today, we know its good to print something and for the rest we do hybrid integration.”

Klaus Hecker, executive director of the OE-A, noted that the flexible and printed electronics market had grown substantially over the last decade.

“Ten years ago, besides OLED displays, it was expected that printed RFID will have a breakthrough and enable item level tagging,” Hecker continued. “We have seen that for various reasons this has been more complicated than expected. But recently the availability of a NFC reader infrastructure with basically every smart phone gives a big boost for printed NFC labels, new products and applications.”

Jason Marsh, director of technology for NextFlex, said that in recent years, flexible hybrid systems have evolved.

“Years ago, everybody was focused on printing silicon-free, very low-cost applications, and it was hard to invest capital in markets with such narrow margins,” Marsh added. “Placing semiconductor elements into these systems gives us more intelligent applications with higher margin opportunities.”

Dominic Miranda, regional account manager for Brewer Science, recalled that a decade ago, the printed electronics industry was preparing to embark on a new era of growth and prosperity with OLED displays and organic photovoltaics (OPVs) leading the way.

“While much of the market potential of those applications was never fully realized, and some of the applications have faded away completely, the fundamental strengths of printed electronics have not changed,” Miranda added. “Displays will continue to be a very strong market for printed electronics, as evidenced in the rapid development and adoption of OLED.

“In retail and packaging, RFID technologies are expanding and becoming more diverse in and of themselves, with more complex and fully integrated devices,” added Miranda. “Consumer electronics, especially in the wearables space, represent a great fit for flexible sensor technologies. Most significantly, the Internet of Things (IoT) has opened the floodgates of potential technologies and applications, particularly for sensors and integrated or hybrid system solutions (flexible hybrid electronics – FHEs) by enabling affordable, ubiquitous sensing for every existing technology.”

Dr. Janos Veres, program manager, novel and printed electronics, Electronic Materials and Devices Laboratory at the Palo Alto Research Center, Inc. (PARC), said that a little more than 10 years ago, printed displays, printed solar and even fully printed RFID were the promise.

“They represented existing markets that were well understood,” Dr. Veres continued. “Significant investments were made in both by large companies as well as startups. These directions did not take off, mostly because they were against incumbent technologies that found their ways to scale and reduce cost in a conventional way. OLED certainly has design appeal and automotive projects are ongoing.

“Over the last 10 years we saw companies focus on simple printed features, such as sensors, traces for heaters and keyboards, interface panels,” Dr. Veres reported. “Glucose test strips remained the number one segment in fully printed devices. Automotive companies began experimenting with in-mold electronics.

“The most important shift that occurred over this time is that we realized that we should not try to beat silicon; in fact, we should use it as part of our toolkit,” Dr. Veres noted. “Printing then becomes an integration technique to deliver unique form factors, integration of soft and hard materials/components, enabling customized, on-demand products at low cost.”

“Applications for OPV, OLED, RFID and compact printed electronic systems are increasing. The strongest markets are organic PV, labels with NFC function and OLED technology for lighting,” said Andrea Glawe of KROENERT GmbH.

“It appears membrane switches, the original printed electronic product, has become very much of commodity, while other printed technologies like printed antennas, printed sensors and medical wearable patches have gained in applications and acceptance,” said Tom Bianchi, VP of Eastprint.

Wearables are an area that Mildner sees as an opportunity for flexible electronics.

“Consumers recognize that wearables today are not wearable - they are thick, inflexible and heavy,” Mildner observed. “Using combinations of silicon and printed electronics will allow more convenient wearables, which consumers will like.”

“The strongest potential FHE growth markets are medical applications in human health and performance monitoring, such as perspiration chemistry for athletes,” Marsh said. “There are opportunities for positive returns on investment in this space. Flexibility and stretchability of flexible hybrid electronics lend to being worn on the human body, as well as on objects such as bridges, pipelines, airplane wings and more. Advanced RFID systems can provide temperature and humidity readings, and now we can monitor strain as well.”

“In-mold electronics in automotive is already gaining traction,” Dr. Veres said. “The same is true for control panels for appliances. The use of new materials and freedom of design is exciting for manufacturers. Smart packaging is emerging; one can see numerous experiments with NFC. This is driven by the need for brands to differentiate and connect more with their customers. Supply chain efficiency is another driver. Wearables are another area where printed sensors, traces and microchips come together in soft, flexible form factors.”

The Future for the Technology

Industry leaders anticipate much more ahead for flexible, hybrid and printed electronics.

Mike O’Reilly, director, Aerosol Jet product management for Optomec, Inc., said he believes that emerging PE technologies will become mainstream manufacturing solutions.

“Packaging will only get smaller and lighter with customization becoming the norm,” O’Reilly said. “Having the flexibility of dynamic digitally driven manufacturing processes will be must haves for leading EMS companies. Significant next-generation PE solutions growth can be expected over the next 10 years.”

Roy Bjorlin, global commercial and strategic initiatives director at Sun Chemical Advanced Materials, said that the future is bright for intelligent inks and electronic packaging.

“Sun Chemical is confident that advancements in material technology will continue to drive the development of new applications, particularly in the flexible printing space,” Bjorlin observed. “Cost drivers in photovoltaics, consumer interest in wearables and smart packaging and new cost-effective displays and lighting will increase demand for new materials and processes.”

Allen Reid, commercial director for NANOGAP, believes that a decade from now, wearables and low cost printed electronics will be commonplace.

“Flexible displays will be on the market in significant numbers,” Reid continued. “Technical drivers will focus on flexibility and durability, as well reducing cost while improving performance. And as costs come down, don’t be surprised to see the development of new, disruptive technologies with these materials.”

“The flexible and printed electronics industry, a decade from now, would be a world where fully printed electronic systems are an integral part of our daily lives,” said Miranda. “Clothing and wearable devices will be seamlessly connecting us unobtrusively (literally and figuratively) in our work and play.”

“Flexible hybrid electronics are ideal for being integrated into devices for a multitude of applications,” said Marsh. “Wearables can give updates on medical conditions continuously and in real time.

And while we have better diagnostics on automobiles than we have on ourselves in 2018, the converse can become true, with continuous medical monitoring made possible and practical through FHE.”

Dr. Veres observed that printing is significant as it enables on-demand fabrication of such systems on much larger areas.

“It also enables complex integration layer by layer,” Veres added. “This means that printing has the potential to become a valuable manufacturing technique for a multitude of electronics devices. Overall, we envisage a printed FHE future taking us closer to create custom solutions to things small or large, embedding intelligence in the fabric of devices around us.”

For Glawe, one major possibility is seeing all glass building facades equipped with organic photovoltaics. He also believes that NFC will change the way we communicate with products.

“The whole product world is communicating with labels with NFC function,” Glawe continued. “Due to functional labels and equipment which can read the labels, our commercial life will totally change. Your mobile phone will communicate with your refrigerator at home and will get information about the food you need to shop for the dinner in the evening. The machine is communicating with the operator in a way that can communicate equipment failure before it will be happen. Innovative sensor systems will be developed in the future to allow all these communications.”

The advantages of the technology – the flexibility, the stretchability, the form factor – are important benefits to designers.

IDTechEx CEO Raghu Das sees the advantages of flexible electronics helping drive future growth.

“The world is moving from hard rigid ‘boxes of electronics’ to softer electronics – electronics that can be curved, be flexed and even stretch, in many guises such as displays, sensors and antennas,” Das continued. “Printed electronics and enabling materials will play a key role in this.”

Stan Farnsworth, chief marketing officer, NovaCentrix, said that he foresees a future where just about everything contains flexible hybrid electronic systems.

“A decade from now, I think most every product we own will incorporate some sort of hybrid printed electronic,” Farnsworth added. “From my discussions with product designers and with my own observations, I believe there will continue to be an evolution in the expectation consumers have regarding the integration of electronics into every-day items. Much of the world is curved, or flexible/dynamic, or both. Electronics designs will adapt to conform with these physical norms which surround us, in the natural world and in the man-made world.”