David Savastano, Editor11.09.18

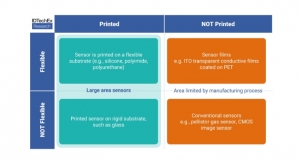

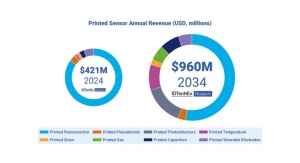

Flexible sensors are an area of great interest in the flexible and printed electronics field. From medical sensors that can conform to the body to the billions of sensors that will be needed to power the Internet of Things, flexible sensors have the potential to be a thriving technology.

Nicholas Skelton, digital marketing manager for Brewer Science, Inc., said the company is seeing more interest in the flexible sensor segment, driven by the potential for flexible form factors.

“Our ability to customize not only form factor but also to supply critical information is creating more direct interest in Brewer Science,” he added. “Over the last year, we have seen an increased interest in printed sensors with flexible form factors and believe that we are starting to see the adoption curve change from just R&D and innovators to more early adopters looking at these products.”

Roy Bjorlin, global commercial and strategic initiatives director, Electronics Materials, Sun Chemical, said he is seeing more interest from end users for flexible and printed sensors.

“End users are very much interested in what is possible with flexible and printed sensors and what is available today,” Bjorlin reported. “It remains somewhat exploratory. The majority of interest is expressed by three key groups – medical device, wearables and consumer brands.”

NextFlex is one aspect aiding the development of flexible sensors. NextFlex brings together companies and academic institutions to create projects with an eye on forming a manufacturing ecosystem for flexible electronic systems. To date, NextFlex has provided more than $59 million in funding to member projects through its Project Call series.

“The idea behind NextFlex, stemming from when it was formed in 2015 through a cooperative agreement with the US Department of Defense, is to promote and advance US manufacturing of flexible hybrid electronics (FHE),” said Dr. Malcolm Thompson, executive director of NextFlex. “NextFlex helps its partners bridge the gap between the production of a prototype and large-scale production. Our members come from the whole FHE ecosystem including high-volume manufacturers like Jabil and Flex.

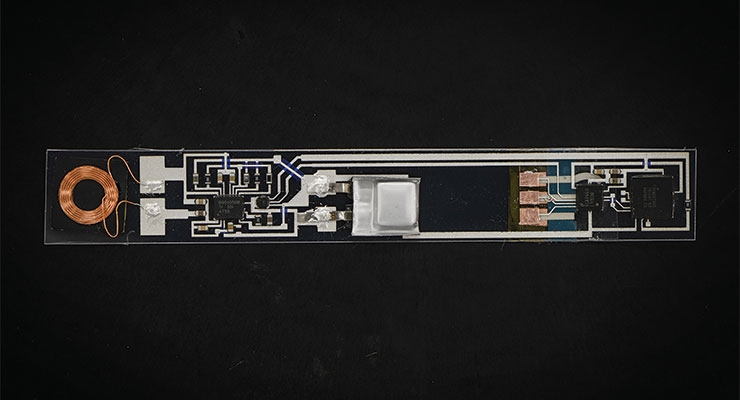

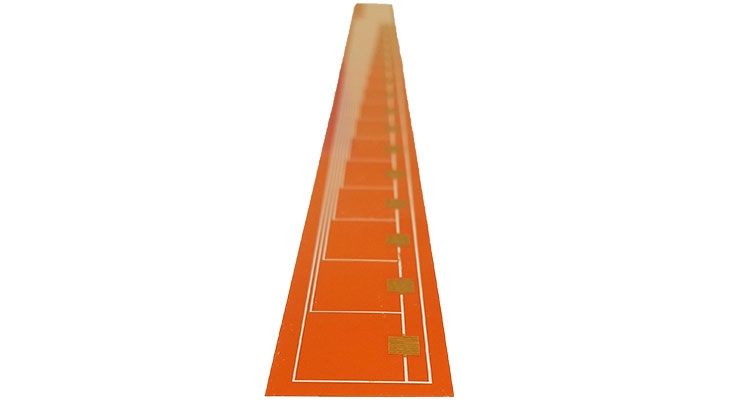

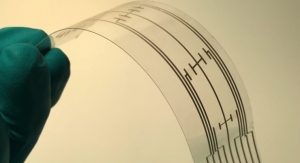

“We create systems on thin polymer (plastic) substrates and we then print the interconnect on the circuit with metal ink,” Dr. Thompson added. “Finally, we place thin silicon chips on the substrate, using the interconnects to fully form the system. These FHE systems that can bend, stretch and twist are enabling applications in aviation, structural health monitoring and healthcare, including electronics that can stick right to the body of an aircraft or body of a person. The weight of these systems is only 30% of the weight of a conventional printed circuit board and is produced in half of the manufacturing steps, so these systems are very appealing for a number of applications.”

Wilfried Bair, senior engineering manager for device integration and packaging at NextFlex, reported that NextFlex is seeing “tremendous interest” in body worn human monitoring systems for medical and fitness monitoring in professional environments.

“FHE is enabling the use of skin conformal and stretchable electronic systems that have found a high level of acceptance with the users,” Bair said. “Compared to a rigid object attached to the body, a Band-Aid-like electronics board is comfortable to wear.

“There are multiple FHE applications close to approval for monitoring blood pressure, pulse oximetry and glucose in a small and lightweight form factor not yet available today,” Bair said. “Printed and conformal antennas are used today in commercial drones to enable high-frequency communication including live video streaming.”

“We continue to see steady work in sensor development around standard flexible technologies such as conductive inks on flexible substrates,” said Stan Farnsworth, chief marketing officer for NovaCentrix. “Where the interest is growing is with the application of new technologies such as the ability to solder standard surface mount components onto polymer films using an evolution of our PulseForge tools. Within a few seconds the components can be soldered to the flexible, printed substrate with no damage to the substrate. Sensor applications range from a variety of bio-med sensors to applications such as X-ray detectors.”

Ultimately, consumers are the key to any technology, and flexible sensors are no exception. Interest, particularly in health solutions, is helping drive growth in this sector.

“Consumers are driving a lot of the interest in flexible hybrid electronics,” Bjorlin said. “As devices become available in personal tracking and some advancement in noninvasive medical testing, consumers are asking for more innovations. Materials suppliers are developing innovative solutions that include new conductor materials such as nanosilver and molecular silver. Both can achieve very fine lines and be applied digitally, which enables smaller more high-density circuity. Other material innovations include the use of graphene as well as new developments in silver chloride electrodes and enzymes formulations.”

“Rapid advances in materials like stretchable conductive inks and flexible device integration methods, combined with accelerated learning in manufacturing methods, are quickly allowing for the market introduction of ‘peel and stick electronics’ that were not viable even a few years ago,” Bair added.

Promising End-Use Markets

There are many possibilities for flexible sensors. For example, Dr. Thompson said that NextFlex is at the forefront of advanced manufacturing development in healthcare, aerospace, structural health monitoring, agriculture, and other applications.

“NextFlex provides a unique forum for unlikely partnerships to form, including between startups and large companies or government agencies,” added Dr. Thompson. “For example, startup Chromera was able to meet Boeing, leading to their collaboration on a flexible condition monitoring sensor array. This forms a unique and valuable network to America’s FHE manufacturing ecosystem, fostering collaboration on projects that have included human wearables and aviation equipment.”

“We’re seeing some exciting applications for FHE in advanced display development and manufacturing, and beyond that, we’re involved in some significant efforts in different automotive applications as well as continued efforts in some bio-med areas,” Farnsworth reported. “One application of innovative sensor technology that is near commercial application is the magnetic resonance imaging (MRI) coil work being done at UC Berkeley by Dr. Ana Claudia Aria’s group. That one is especially exciting because it will help children receive much better imaging results and overall have a better diagnostic experience.”

“Medical diagnostics and patient tracking appear to be leading the way,” Bjorlin said. “Noninvasive monitoring of glucose and some cardiac functions are creating a lot of demand. Of course, the Internet of Things and the commensurate infrastructure is already being built to support the anticipated demand. This infrastructure will also enable the consumer brand groups to support item-level tagging and smart surfaces which drive the consumer experience in the retail space.”

Bjorlin said that Sun Chemical is seeing a wide range of applications for its technology.

“There are exciting developments in a range of markets, including wearables in medical diagnostics,” he noted. “New solutions in materials development and fine line printing are enabling higher density circuits. Development in graphene technology offers new solutions to onboard printed components, as well as developments in new adhesives for attaching components and other innovations in pressure sensitive adhesives and liquid adhesives. Printed batteries are another interesting area. Combining these solutions will enable designers to offer smaller, more comfortable wearable sensors for consumers, as well as lower cost solutions for commercial applications in the consumer packaged goods space.”

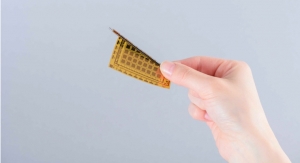

Sri Peruvemba, VP of strategy, BeBop Sensors, said that end-users in consumer, industrial, medical and automotive industries are looking for a solution to solve a real problem in their industry.

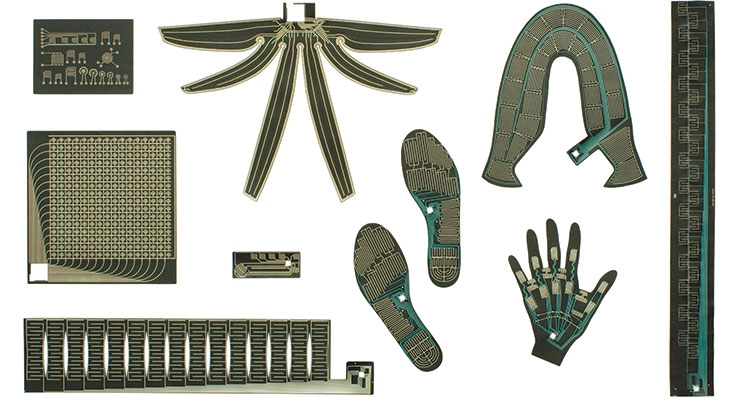

“BeBop’s primary goal has been to connect squishy humans to rigid computers so that the quality of our life improves greatly and constantly,” Peruvemba said. “To do this, we have been making fabric-based sensors that can adapt to us ‘squishy’ humans (our wrists, feet, head, etc. are not flat, are not rigid and don’t conform to a spec) to computers that can take the data from the sensors and return a treasure trove of information back to us that we can use to improve our lives, from medical safety to industrial productivity to sports and entertainment.

“We are seeing the most traction in industrial, medical, transportation and consumer applications, there are quite a few within each of these applications,” Peruvemba added. “There is no dearth to new applications.”

“Human monitoring and medical diagnostics continue to be at the forefront of FHE technology use,” Bair said. “Soft robotics, ranging from harvesting delicate fruit to body worn exoskeletons to aid in recovery after surgery or injury, is a highly promising technology currently in development and about three to five years away from commercial availability.”

Bair added that NextFlex is currently working with a Bay Area-based medical device company to convert a rigid body-worn sensor for noninvasive body monitoring into a thin and lightweight flexible system.

Skelton noted that Brewer Science is pursuing many different end-use markets.

“Because we are able to be highly customizable, the end-use markets are nearly limitless for applications that require precision and repeatability,” Skelton said. “We have found that there are three main key markets where FHE will proliferate: industrial IoT (IIoT), environmental monitoring and air monitoring. All of these markets have their challenges but all represent an opportunity in that they require real-time data in a flexible form factor that can be customized and lightweight.

“There are a couple of unique projects we are currently working on, but one of our IIoT projects has been one of the most exciting and challenging,” Skelton added. “We are working on taking over 30,000 data points to create a fingerprint from all the data to predict the wear and tear of specific mechanical parts while in the process to reduce costs from unnecessary preventative maintenance.”

Challenges Ahead

There are significant obstacles ahead, beginning with reaching full-scale manufacturing. Bair noted that transitioning design and manufacturing technologies from pilot volumes into high volume manufacturing is a challenge that requires significant capital investment to create new production lines.

Customization is also key, as flexible sensors are not a one-size-fits-all device.

“Demand can suddenly skyrocket, and various customers may require different characterization due to the design flexibility of this technology,” said Skelton. “We are no longer confined to a mass-produced device case or rigid circuit board. With the thin and flexible properties of FHE, we can place sensors in locations not previously achievable. With this design, flexibility brings engineering and manufacturing challenges as most designs have some level of customization required.”

Outlook for the Flexible Sensor Market

With all of this in place and still more coming in the future, industry leaders say they see many new opportunities ahead for the next five to 10 years.

“I am very optimistic,” Bjorlin said. “Medical device sensors will likely lead in terms of short-term growth followed closely by the consumer brand space. We are already seeing innovative new printed sensors in each of these markets already. Consumers are getting a taste for what’s possible and will drive further innovations. This will also lead to the supporting manufacturing and design infrastructure becoming aligned.”

“Based on the trends we are seeing, and on what we see with our own technology and product roadmap plus what our customers are telling us, we see strong growth potential,” Farnsworth said.

“The challenges associated with the growth of this new business area are very exciting,” Skelton noted. “There are many unknowns in the market that need to be figured out, but we thrive on coming up with new and unique solutions to impact the world in a meaningful and sustainable way.”

“We see billions of sensors being deployed in a variety of applications that will improve our lives,” Peruvemba added. “Our customers are creating all of this magic. We are providing them with a valuable ingredient.”

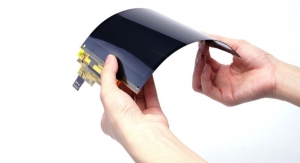

“As other electronic devices become flexible – in particular with the advent of flexible and foldable displays – the electronics sector will move into lightweight and conformal electronics, which will be pervasive and almost invisible compared to today’s ‘boxed-in’ electronics,” Bair concluded.

Nicholas Skelton, digital marketing manager for Brewer Science, Inc., said the company is seeing more interest in the flexible sensor segment, driven by the potential for flexible form factors.

“Our ability to customize not only form factor but also to supply critical information is creating more direct interest in Brewer Science,” he added. “Over the last year, we have seen an increased interest in printed sensors with flexible form factors and believe that we are starting to see the adoption curve change from just R&D and innovators to more early adopters looking at these products.”

Roy Bjorlin, global commercial and strategic initiatives director, Electronics Materials, Sun Chemical, said he is seeing more interest from end users for flexible and printed sensors.

“End users are very much interested in what is possible with flexible and printed sensors and what is available today,” Bjorlin reported. “It remains somewhat exploratory. The majority of interest is expressed by three key groups – medical device, wearables and consumer brands.”

NextFlex is one aspect aiding the development of flexible sensors. NextFlex brings together companies and academic institutions to create projects with an eye on forming a manufacturing ecosystem for flexible electronic systems. To date, NextFlex has provided more than $59 million in funding to member projects through its Project Call series.

“The idea behind NextFlex, stemming from when it was formed in 2015 through a cooperative agreement with the US Department of Defense, is to promote and advance US manufacturing of flexible hybrid electronics (FHE),” said Dr. Malcolm Thompson, executive director of NextFlex. “NextFlex helps its partners bridge the gap between the production of a prototype and large-scale production. Our members come from the whole FHE ecosystem including high-volume manufacturers like Jabil and Flex.

“We create systems on thin polymer (plastic) substrates and we then print the interconnect on the circuit with metal ink,” Dr. Thompson added. “Finally, we place thin silicon chips on the substrate, using the interconnects to fully form the system. These FHE systems that can bend, stretch and twist are enabling applications in aviation, structural health monitoring and healthcare, including electronics that can stick right to the body of an aircraft or body of a person. The weight of these systems is only 30% of the weight of a conventional printed circuit board and is produced in half of the manufacturing steps, so these systems are very appealing for a number of applications.”

Wilfried Bair, senior engineering manager for device integration and packaging at NextFlex, reported that NextFlex is seeing “tremendous interest” in body worn human monitoring systems for medical and fitness monitoring in professional environments.

“FHE is enabling the use of skin conformal and stretchable electronic systems that have found a high level of acceptance with the users,” Bair said. “Compared to a rigid object attached to the body, a Band-Aid-like electronics board is comfortable to wear.

“There are multiple FHE applications close to approval for monitoring blood pressure, pulse oximetry and glucose in a small and lightweight form factor not yet available today,” Bair said. “Printed and conformal antennas are used today in commercial drones to enable high-frequency communication including live video streaming.”

“We continue to see steady work in sensor development around standard flexible technologies such as conductive inks on flexible substrates,” said Stan Farnsworth, chief marketing officer for NovaCentrix. “Where the interest is growing is with the application of new technologies such as the ability to solder standard surface mount components onto polymer films using an evolution of our PulseForge tools. Within a few seconds the components can be soldered to the flexible, printed substrate with no damage to the substrate. Sensor applications range from a variety of bio-med sensors to applications such as X-ray detectors.”

Ultimately, consumers are the key to any technology, and flexible sensors are no exception. Interest, particularly in health solutions, is helping drive growth in this sector.

“Consumers are driving a lot of the interest in flexible hybrid electronics,” Bjorlin said. “As devices become available in personal tracking and some advancement in noninvasive medical testing, consumers are asking for more innovations. Materials suppliers are developing innovative solutions that include new conductor materials such as nanosilver and molecular silver. Both can achieve very fine lines and be applied digitally, which enables smaller more high-density circuity. Other material innovations include the use of graphene as well as new developments in silver chloride electrodes and enzymes formulations.”

“Rapid advances in materials like stretchable conductive inks and flexible device integration methods, combined with accelerated learning in manufacturing methods, are quickly allowing for the market introduction of ‘peel and stick electronics’ that were not viable even a few years ago,” Bair added.

Promising End-Use Markets

There are many possibilities for flexible sensors. For example, Dr. Thompson said that NextFlex is at the forefront of advanced manufacturing development in healthcare, aerospace, structural health monitoring, agriculture, and other applications.

“NextFlex provides a unique forum for unlikely partnerships to form, including between startups and large companies or government agencies,” added Dr. Thompson. “For example, startup Chromera was able to meet Boeing, leading to their collaboration on a flexible condition monitoring sensor array. This forms a unique and valuable network to America’s FHE manufacturing ecosystem, fostering collaboration on projects that have included human wearables and aviation equipment.”

“We’re seeing some exciting applications for FHE in advanced display development and manufacturing, and beyond that, we’re involved in some significant efforts in different automotive applications as well as continued efforts in some bio-med areas,” Farnsworth reported. “One application of innovative sensor technology that is near commercial application is the magnetic resonance imaging (MRI) coil work being done at UC Berkeley by Dr. Ana Claudia Aria’s group. That one is especially exciting because it will help children receive much better imaging results and overall have a better diagnostic experience.”

“Medical diagnostics and patient tracking appear to be leading the way,” Bjorlin said. “Noninvasive monitoring of glucose and some cardiac functions are creating a lot of demand. Of course, the Internet of Things and the commensurate infrastructure is already being built to support the anticipated demand. This infrastructure will also enable the consumer brand groups to support item-level tagging and smart surfaces which drive the consumer experience in the retail space.”

Bjorlin said that Sun Chemical is seeing a wide range of applications for its technology.

“There are exciting developments in a range of markets, including wearables in medical diagnostics,” he noted. “New solutions in materials development and fine line printing are enabling higher density circuits. Development in graphene technology offers new solutions to onboard printed components, as well as developments in new adhesives for attaching components and other innovations in pressure sensitive adhesives and liquid adhesives. Printed batteries are another interesting area. Combining these solutions will enable designers to offer smaller, more comfortable wearable sensors for consumers, as well as lower cost solutions for commercial applications in the consumer packaged goods space.”

Sri Peruvemba, VP of strategy, BeBop Sensors, said that end-users in consumer, industrial, medical and automotive industries are looking for a solution to solve a real problem in their industry.

“BeBop’s primary goal has been to connect squishy humans to rigid computers so that the quality of our life improves greatly and constantly,” Peruvemba said. “To do this, we have been making fabric-based sensors that can adapt to us ‘squishy’ humans (our wrists, feet, head, etc. are not flat, are not rigid and don’t conform to a spec) to computers that can take the data from the sensors and return a treasure trove of information back to us that we can use to improve our lives, from medical safety to industrial productivity to sports and entertainment.

“We are seeing the most traction in industrial, medical, transportation and consumer applications, there are quite a few within each of these applications,” Peruvemba added. “There is no dearth to new applications.”

“Human monitoring and medical diagnostics continue to be at the forefront of FHE technology use,” Bair said. “Soft robotics, ranging from harvesting delicate fruit to body worn exoskeletons to aid in recovery after surgery or injury, is a highly promising technology currently in development and about three to five years away from commercial availability.”

Bair added that NextFlex is currently working with a Bay Area-based medical device company to convert a rigid body-worn sensor for noninvasive body monitoring into a thin and lightweight flexible system.

Skelton noted that Brewer Science is pursuing many different end-use markets.

“Because we are able to be highly customizable, the end-use markets are nearly limitless for applications that require precision and repeatability,” Skelton said. “We have found that there are three main key markets where FHE will proliferate: industrial IoT (IIoT), environmental monitoring and air monitoring. All of these markets have their challenges but all represent an opportunity in that they require real-time data in a flexible form factor that can be customized and lightweight.

“There are a couple of unique projects we are currently working on, but one of our IIoT projects has been one of the most exciting and challenging,” Skelton added. “We are working on taking over 30,000 data points to create a fingerprint from all the data to predict the wear and tear of specific mechanical parts while in the process to reduce costs from unnecessary preventative maintenance.”

Challenges Ahead

There are significant obstacles ahead, beginning with reaching full-scale manufacturing. Bair noted that transitioning design and manufacturing technologies from pilot volumes into high volume manufacturing is a challenge that requires significant capital investment to create new production lines.

Customization is also key, as flexible sensors are not a one-size-fits-all device.

“Demand can suddenly skyrocket, and various customers may require different characterization due to the design flexibility of this technology,” said Skelton. “We are no longer confined to a mass-produced device case or rigid circuit board. With the thin and flexible properties of FHE, we can place sensors in locations not previously achievable. With this design, flexibility brings engineering and manufacturing challenges as most designs have some level of customization required.”

Outlook for the Flexible Sensor Market

With all of this in place and still more coming in the future, industry leaders say they see many new opportunities ahead for the next five to 10 years.

“I am very optimistic,” Bjorlin said. “Medical device sensors will likely lead in terms of short-term growth followed closely by the consumer brand space. We are already seeing innovative new printed sensors in each of these markets already. Consumers are getting a taste for what’s possible and will drive further innovations. This will also lead to the supporting manufacturing and design infrastructure becoming aligned.”

“Based on the trends we are seeing, and on what we see with our own technology and product roadmap plus what our customers are telling us, we see strong growth potential,” Farnsworth said.

“The challenges associated with the growth of this new business area are very exciting,” Skelton noted. “There are many unknowns in the market that need to be figured out, but we thrive on coming up with new and unique solutions to impact the world in a meaningful and sustainable way.”

“We see billions of sensors being deployed in a variety of applications that will improve our lives,” Peruvemba added. “Our customers are creating all of this magic. We are providing them with a valuable ingredient.”

“As other electronic devices become flexible – in particular with the advent of flexible and foldable displays – the electronics sector will move into lightweight and conformal electronics, which will be pervasive and almost invisible compared to today’s ‘boxed-in’ electronics,” Bair concluded.