11.29.18

Butler Technologies, ACI Materials, Principled Design, and Lubrizol have partnered to produces an innovative fashion-functional Multi-Tech Commuter Jacket, which provides warmth on demand powered by flexible printed electronics.

The Multi-Tech Commuter Jacket was commissioned by Lubrizol with the purpose of demonstrating how solutions and supply chain partners can be integrated to deliver innovative, valuable solutions to the wearables market.

The Multi-Tech Commuter Jacket is the result of an impressive multiple-partner collaboration that took the project from concept to completion in nine months. This project underscores the importance of systems thinking in the development of novel wearable electronics — combining design, material science, applications know-how, and value chain partners having the right mindset and capabilities – to quickly turn innovative ideas into prototypes and then commercial scale realities.

Lubrizol commissioned Despina Papadopoulos from Principled Design in New York to design and oversee development of Lubrizol’s Multi-Tech Commuter Jacket, including the development of the supply chain, and contract assembly of jacket components into final garment form. The jacket showcases innovative technologies from Lubrizol’s Engineered Polymers and Performance Coatings portfolios, which are well-suited for electronics including flexible hybrid electronics, wearables, mobile devices and accessories, and 3D printing.

“Designing fashion-forward, clothing that incorporates advanced technology requires a village, and that’s exactly what happened here. Through open communications and the sharing of expertise resulted in the MTC Jacket. The whole experience was very positive, and we are looking forward to the next steps,” said Papadopoulos.

To incorporate Lubrizol’s highly flexible material solutions into a wearable platform, Principled Design then selected ACI Materials for their expertise in conductive inks, encapsulants and resistance heater flexible circuit technology, and Butler Technologies, Inc. for their capabilities in designing, developing printed electronics, from proof of concept and prototyping to full-scale production.

“We produced the printed heaters with scalability in mind. Using high precision screen printing that allows us to manufacture the circuit consistently and efficiently on a large scale,” said Todd Gray, project lead for Butler Technologies.

Designed for stylish and functional street-to-office wearability, the Multi-Tech Commuter Jacket features Lubrizol materials that ensure function, comfort and durability over the life of the garment. Stretch denim and polyester fabrics move and breathe with the wearer for comfortable motion and mobility. ACI’s flexible circuit heating element with stretchable encapsulation providing protection for conductive traces located across the inside of the jacket’s back provides warmth on demand – without the bulk of additional clothing layers. Fabric treatment at the elbows and palms with Lubrizol coating technology enhances garment durability both in-use and when laundering.

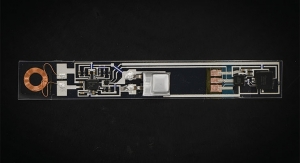

The Multi-Tech Commuter Jacket.. (Source: Butler Technologies)

The Multi-Tech Commuter Jacket was commissioned by Lubrizol with the purpose of demonstrating how solutions and supply chain partners can be integrated to deliver innovative, valuable solutions to the wearables market.

The Multi-Tech Commuter Jacket is the result of an impressive multiple-partner collaboration that took the project from concept to completion in nine months. This project underscores the importance of systems thinking in the development of novel wearable electronics — combining design, material science, applications know-how, and value chain partners having the right mindset and capabilities – to quickly turn innovative ideas into prototypes and then commercial scale realities.

Lubrizol commissioned Despina Papadopoulos from Principled Design in New York to design and oversee development of Lubrizol’s Multi-Tech Commuter Jacket, including the development of the supply chain, and contract assembly of jacket components into final garment form. The jacket showcases innovative technologies from Lubrizol’s Engineered Polymers and Performance Coatings portfolios, which are well-suited for electronics including flexible hybrid electronics, wearables, mobile devices and accessories, and 3D printing.

“Designing fashion-forward, clothing that incorporates advanced technology requires a village, and that’s exactly what happened here. Through open communications and the sharing of expertise resulted in the MTC Jacket. The whole experience was very positive, and we are looking forward to the next steps,” said Papadopoulos.

To incorporate Lubrizol’s highly flexible material solutions into a wearable platform, Principled Design then selected ACI Materials for their expertise in conductive inks, encapsulants and resistance heater flexible circuit technology, and Butler Technologies, Inc. for their capabilities in designing, developing printed electronics, from proof of concept and prototyping to full-scale production.

“We produced the printed heaters with scalability in mind. Using high precision screen printing that allows us to manufacture the circuit consistently and efficiently on a large scale,” said Todd Gray, project lead for Butler Technologies.

Designed for stylish and functional street-to-office wearability, the Multi-Tech Commuter Jacket features Lubrizol materials that ensure function, comfort and durability over the life of the garment. Stretch denim and polyester fabrics move and breathe with the wearer for comfortable motion and mobility. ACI’s flexible circuit heating element with stretchable encapsulation providing protection for conductive traces located across the inside of the jacket’s back provides warmth on demand – without the bulk of additional clothing layers. Fabric treatment at the elbows and palms with Lubrizol coating technology enhances garment durability both in-use and when laundering.

The Multi-Tech Commuter Jacket.. (Source: Butler Technologies)