10.04.17

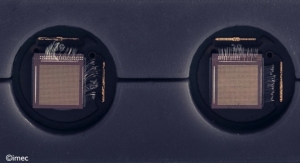

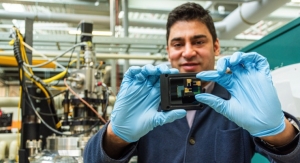

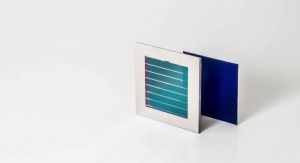

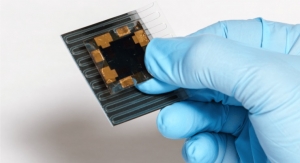

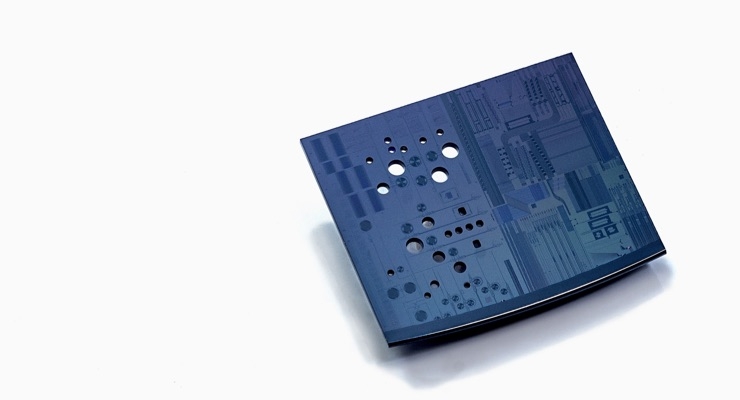

Imec unveiled at its Imec Technology Forum (ITF) Health a pressure sensor based on micro-optomechanical systems (MOMS) technology. The sensor exhibits measurement precision in a large pressure range while being compact, resistant to electromagnetic interference (EMI), and having multiplexing capabilities. Leveraging imec’s technical expertise in both MEMS and photonics, the sensor can be used in applications that require high-quality sensing, notably in the medical and life sciences domains.

“Our advanced sensor could be used in a variety of (biomedical) applications such as intracranial pressure or intravascular blood pressure monitoring, where high-quality remote sensing is required. The sensor has also proven its biocompatibility and can be used in combination with MRI technology as there are no metal parts,” said Xavier Rottenberg, principal member of the technical staff at imec. “With our current demonstrator, and the high performance it achieves on a large pressure range, imec has demonstrated the superior performance of MOMS-based pressure sensors and their potential to complement – and in some applications even replace – current MEMS-based devices.”

Pressure sensors to measure parameters such as altitude and depth, or to engage in flow sensing are currently based on either MEMS or optical fiber technologies, which bring both advantages and shortcomings. MEMS-based pressure sensors are popular as they are known for their good performance and small size. Optical fiber sensors are suitable for use in harsh environments that can be characterized by EMI or high temperatures. However, they make for less integrated and more complex and expensive systems. Imec’s new MOMS-based pressure sensor shows high tolerance to EMI interference and supports multiplexing.

Imec’s Micro-Optomechanical Pressure Sensor. (Source: Imec)

“Our advanced sensor could be used in a variety of (biomedical) applications such as intracranial pressure or intravascular blood pressure monitoring, where high-quality remote sensing is required. The sensor has also proven its biocompatibility and can be used in combination with MRI technology as there are no metal parts,” said Xavier Rottenberg, principal member of the technical staff at imec. “With our current demonstrator, and the high performance it achieves on a large pressure range, imec has demonstrated the superior performance of MOMS-based pressure sensors and their potential to complement – and in some applications even replace – current MEMS-based devices.”

Pressure sensors to measure parameters such as altitude and depth, or to engage in flow sensing are currently based on either MEMS or optical fiber technologies, which bring both advantages and shortcomings. MEMS-based pressure sensors are popular as they are known for their good performance and small size. Optical fiber sensors are suitable for use in harsh environments that can be characterized by EMI or high temperatures. However, they make for less integrated and more complex and expensive systems. Imec’s new MOMS-based pressure sensor shows high tolerance to EMI interference and supports multiplexing.

Imec’s Micro-Optomechanical Pressure Sensor. (Source: Imec)