09.13.18

Safety helmets with built-in microdisplays and multifunction data glasses will soon monitor production lines, advise workers of dangers, and display storage locations. The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP is developing OLED microdisplays and sensors as the foundation for intelligent data glasses in the sectors of medicine, vehicle production, entertainment, and for Industry 4.0.

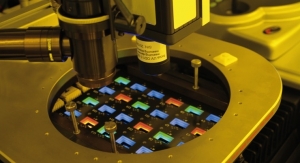

The respective display design and parameters such as resolution, pixel size, and supplementary functions can be varied and combined depending on the application, such as for monitoring manufacturing processes or in logistics. The range of displays runs from high-resolution microdisplays in extended full HD for AR/VR applications to variants with ultra-low power consumption for consumer wearables. Evaluation kits are available from Fraunhofer FEP as development tools.

The scientists at Fraunhofer FEP in Dresden specialize in the development of custom microdisplays for AR and VR data glasses. The microdisplays take advantage of OLED-on-silicon technology. In contrast to other display types, no supplementary illumination is required for OLED microdisplays, as they are themselves luminescent.

“The compact displays are particularly suitable for use in industrial applications. For example, they can be mounted in glasses and thus provide production personnel or machinery operators with all the information needed, like picking station or part numbers,“ explains Dr. Uwe Vogel, head of the Microdisplays and Sensors division at the Fraunhofer FEP.

Currently Fraunhofer FEP is working together with partners in the joint project “Glass@Service,” which include Siemens, UVEX, and Ubimax among others, on use cases for data glasses in Industry 4.0. Logistics represents one of the major fields of application. Thanks to data glasses, a warehouse clerk can have both hands free for activities and is continuously guided through individual processes via the display in the glasses. The clerk can be dedicated entirely to the primary task at hand, while all the data – what has been picked, packed, and where it goes next – is simultaneously transferred.

However, the researchers see unsolved challenges ahead that they want to tackle, especially for microdisplays in consumer-ready Augmented Reality (AR) glasses: higher brightness, good yield for large (chip) areas, curved surfaces for more compact optics, irregular pixel matrices with even higher pixel densities, integrated eye tracking, and transparent substrates.

Source: Fraunhofer FEP.

The respective display design and parameters such as resolution, pixel size, and supplementary functions can be varied and combined depending on the application, such as for monitoring manufacturing processes or in logistics. The range of displays runs from high-resolution microdisplays in extended full HD for AR/VR applications to variants with ultra-low power consumption for consumer wearables. Evaluation kits are available from Fraunhofer FEP as development tools.

The scientists at Fraunhofer FEP in Dresden specialize in the development of custom microdisplays for AR and VR data glasses. The microdisplays take advantage of OLED-on-silicon technology. In contrast to other display types, no supplementary illumination is required for OLED microdisplays, as they are themselves luminescent.

“The compact displays are particularly suitable for use in industrial applications. For example, they can be mounted in glasses and thus provide production personnel or machinery operators with all the information needed, like picking station or part numbers,“ explains Dr. Uwe Vogel, head of the Microdisplays and Sensors division at the Fraunhofer FEP.

Currently Fraunhofer FEP is working together with partners in the joint project “Glass@Service,” which include Siemens, UVEX, and Ubimax among others, on use cases for data glasses in Industry 4.0. Logistics represents one of the major fields of application. Thanks to data glasses, a warehouse clerk can have both hands free for activities and is continuously guided through individual processes via the display in the glasses. The clerk can be dedicated entirely to the primary task at hand, while all the data – what has been picked, packed, and where it goes next – is simultaneously transferred.

However, the researchers see unsolved challenges ahead that they want to tackle, especially for microdisplays in consumer-ready Augmented Reality (AR) glasses: higher brightness, good yield for large (chip) areas, curved surfaces for more compact optics, irregular pixel matrices with even higher pixel densities, integrated eye tracking, and transparent substrates.

Source: Fraunhofer FEP.