11.08.18

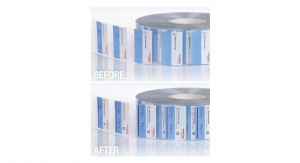

PragmatIC announced a strategic collaboration with Smooth & Sharp Corporation (S&S), a supplier of RFID inlays and manufacturing tools, which will accelerate the adoption of PragmatIC’s flexible integrated circuits (FlexICs).

S&S has experience designing manufacturing equipment for traditional silicon inlays, which they have adapted to deliver a new flip-chip machine for PragmatIC’s FlexICs. With a throughput of 4,200 UPH (parts per hour), the new machine offers the lowest up-front cost for assembly of FlexICs onto paper or plastic inlays.

The new machine has been demonstrated not only with conventional aluminum antennas, but also a range of antennas produced by S&S using flexographic, inkjet and screen printing. The availability of printed electronic solutions further lowers the cost barrier for RFID inlays.

This change in cost, coupled with the thin, flexible and robust nature of FlexICs, opens up the potential for consumer goods brands to rapidly adopt and scale new smart packaging solutions based on RFID and NFC functionality that was previously unaffordable.

“We are very excited that Smooth & Sharp Corporation is delivering solutions that enable the integration of our unique technology for ultra-low-cost flexible electronics,” said Scott White, CEO of PragmatIC. “Our strong portfolio of partners, including our global RFID and NFC inlay manufacturers, ensures that the worlds’ largest consumer brands can now add intelligence into everyday items.”

“Smooth & Sharp Corporation is focused on delivering the best solutions for our customers” added Alan Wu, CEO of S&S. “Combining PragmatIC’s novel FlexICs with our printed antennas on low-cost substrates will bring significant advantages for customers who want to add RFID and NFC to a more diverse range of inexpensive products.”

Source: PragmatIC.

S&S has experience designing manufacturing equipment for traditional silicon inlays, which they have adapted to deliver a new flip-chip machine for PragmatIC’s FlexICs. With a throughput of 4,200 UPH (parts per hour), the new machine offers the lowest up-front cost for assembly of FlexICs onto paper or plastic inlays.

The new machine has been demonstrated not only with conventional aluminum antennas, but also a range of antennas produced by S&S using flexographic, inkjet and screen printing. The availability of printed electronic solutions further lowers the cost barrier for RFID inlays.

This change in cost, coupled with the thin, flexible and robust nature of FlexICs, opens up the potential for consumer goods brands to rapidly adopt and scale new smart packaging solutions based on RFID and NFC functionality that was previously unaffordable.

“We are very excited that Smooth & Sharp Corporation is delivering solutions that enable the integration of our unique technology for ultra-low-cost flexible electronics,” said Scott White, CEO of PragmatIC. “Our strong portfolio of partners, including our global RFID and NFC inlay manufacturers, ensures that the worlds’ largest consumer brands can now add intelligence into everyday items.”

“Smooth & Sharp Corporation is focused on delivering the best solutions for our customers” added Alan Wu, CEO of S&S. “Combining PragmatIC’s novel FlexICs with our printed antennas on low-cost substrates will bring significant advantages for customers who want to add RFID and NFC to a more diverse range of inexpensive products.”

Source: PragmatIC.